Method for improving oxidation yield of hydrogenated liquid of hydrogen peroxide prepared by utilizing anthraquinone process

A technology of hydrogen peroxide and hydrogenation liquid, applied in the directions of peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of increasing the danger of oxidation tower equipment It can solve the problems of stability, low yield of hydrogen peroxide products, and low hydrogen peroxide stabilization ability, so as to achieve the effects of increasing product revenue, improving stability and reducing emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

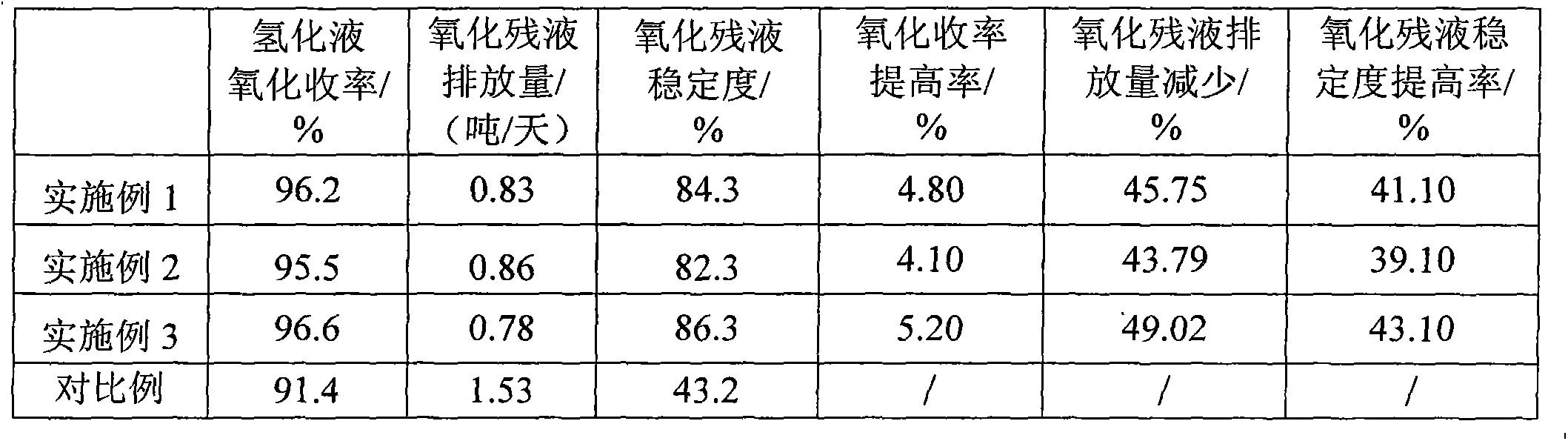

[0017] On the device for producing hydrogen peroxide by anthraquinone method, ethylenediaminetetramethylenephosphonic acid and water are mixed according to the mass fraction of 25% ethylenediaminetetramethylenephosphonic acid and 75% water in the phosphoric acid solution preparation tank. Acid solution, through the hydrogenation liquid pump and the hydrogenation liquid whose hydrogenation efficiency is 7.6g / L, the volume ratio is 1:(3×10 4 ) into the oxidation tower to react with air after being mixed, and the oxidation residue is discharged from the bottom of the tower. The oxidation reaction temperature is 50°C, and the pressure of the oxidation tail gas is 0.22MPa. The experimental results are shown in Table 1.

Embodiment 2

[0019] On the same hydrogen peroxide production device, in the phosphoric acid solution preparation tank, citric acid, phosphoric acid, and water are formulated into a compound acid solution according to the mass fraction of citric acid 10%, phosphoric acid 30%, and water 60%. The hydrogenation liquid of the same hydrogenation efficiency of embodiment 1 is by volume ratio 1: (5 * 10 4 ) into the oxidation tower to react with air after mixing. Others are the same as embodiment 1. The experimental results are shown in Table 1.

Embodiment 3

[0021] On the same hydrogen peroxide production device, polyacrylic acid, phosphoric acid, water are made into composite acid solution by mass fraction polyacrylic acid (number average molecular weight 3000) 2%, phosphoric acid 40%, water 58% in the phosphoric acid solution preparation tank, through The hydrogenated liquid pump and the hydrogenated liquid with the same hydrogenation efficiency as in Example 1 are in volume ratio 1: (10×10 4 ) into the oxidation tower to react with air after mixing. Others are the same as embodiment 1. The experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com