Automatic detection method of battery positive-negative electrode lug terminal length

An automatic detection, positive and negative technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of increasing labor costs and management costs, unable to meet speed requirements, unable to guarantee accuracy, etc., to achieve stable, accurate and efficient dimensions Automatic detection, to achieve the effect of automatic size detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

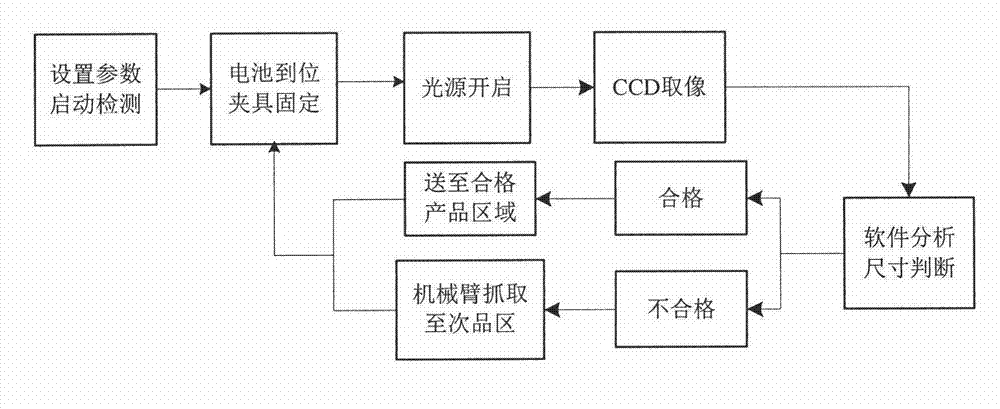

[0017] First, the process parameters of the current batch of battery tabs are set on the host computer (8), and then the detection is started.

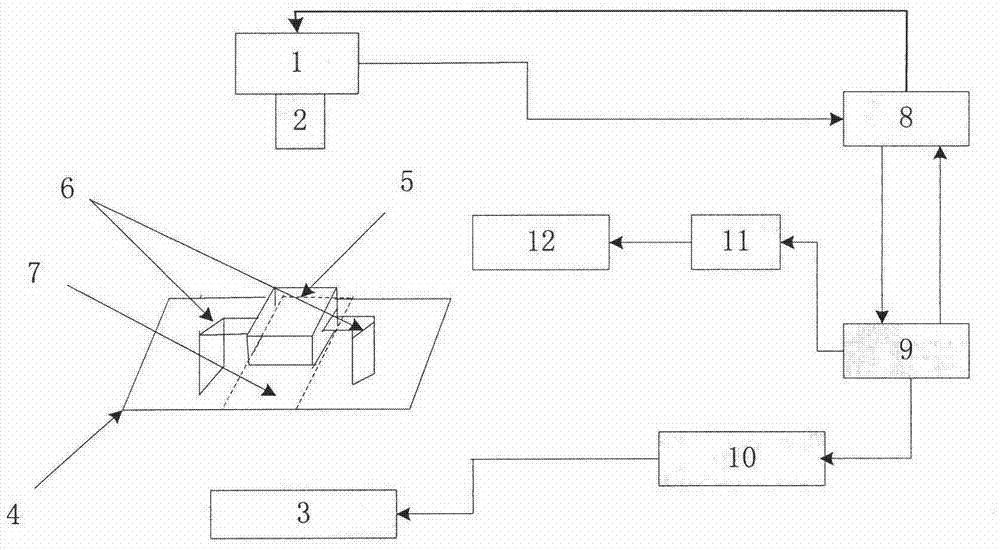

[0018] When starting the test, the product to be tested (5) is manually placed on the feeding area of the test table (4), and the PLC (9) controls the action of the fixture (6) to fix the product to be tested (5), and then the PLC (9) Control the slide rail on the testing platform (4) to move the product to be tested (5) to the right below the industrial CCD (1), that is, the designated area above the organic transparent glass plate (7) in the middle of the testing platform (4). The PLC (9) sends a light source signal to the 7250I / O card (10). After the LED blue backlight (3) is turned on, the PLC (9) sends a trigger signal to the CCD (1) through the upper computer (8), and the CCD ( 1) Complete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com