Patents

Literature

68results about How to "Real-time display of test results" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grid fault diagnosis method based on data mining

InactiveCN103728507AReal-time display of test resultsReal-time displayElectrical testingSpecial data processing applicationsRough setFailure diagnosis

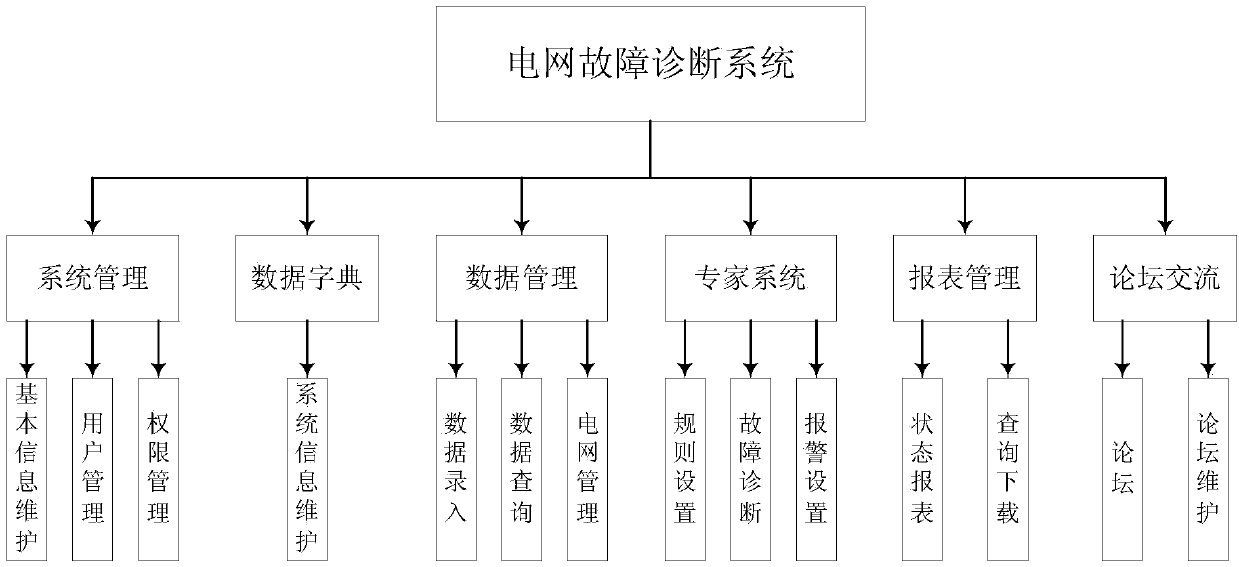

The invention discloses a grid fault diagnosis method based on data mining. On the basis of the characteristics that grid measurement data quantity is large and dimensionality is high, grid fault diagnosis is achieved by means of a data mining technique. Firstly, the data correlation degree is evaluated by means of a neighborhood rough set method, reduction processing is carried out on data by means of a greedy search algorithm, then failure diagnoses are classified according to features by means of a competition coagulation clustering algorithm, and then failure diagnosis of a grid is achieved on the basis of a fuzzy association rule algorithm. According to the method, failure detection, classification and positioning of various devices and elements which break down in the grid with mass data can be carried out, ultimately, an IDEA integrated development tool and an MySQL database are used, an object-oriented program design concept is adopted, and a grid failure diagnosis system in a B / S mode is developed.

Owner:芜湖大学科技园发展有限公司

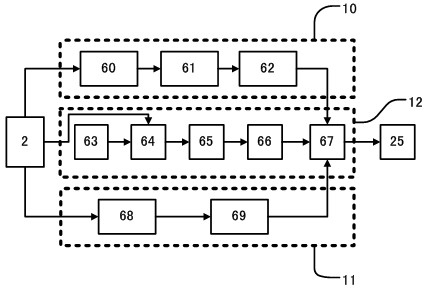

Circuit structure and method for automatically testing analog baseband chip comprising analog-digital converter (ADC) and digital-analog converter (DAC)

ActiveCN102207535AEasy to buildReduce complexityElectronic circuit testingDigital down converterWork performance

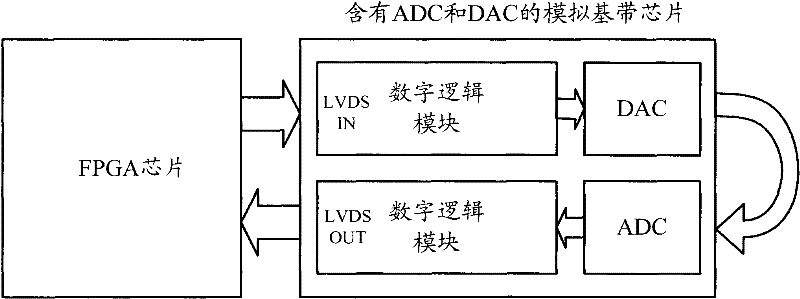

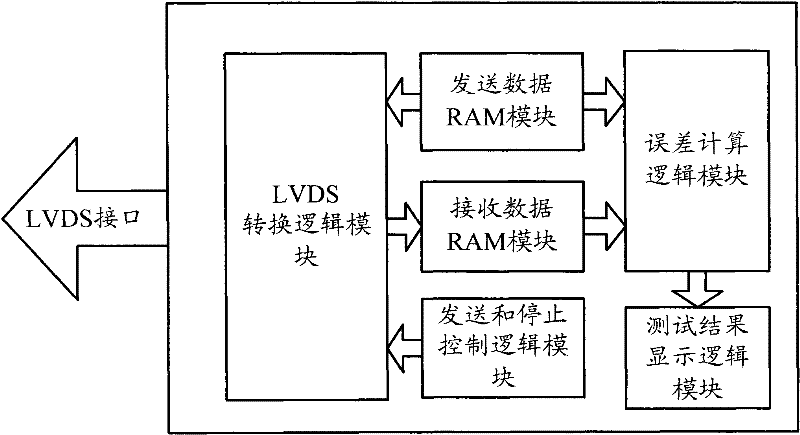

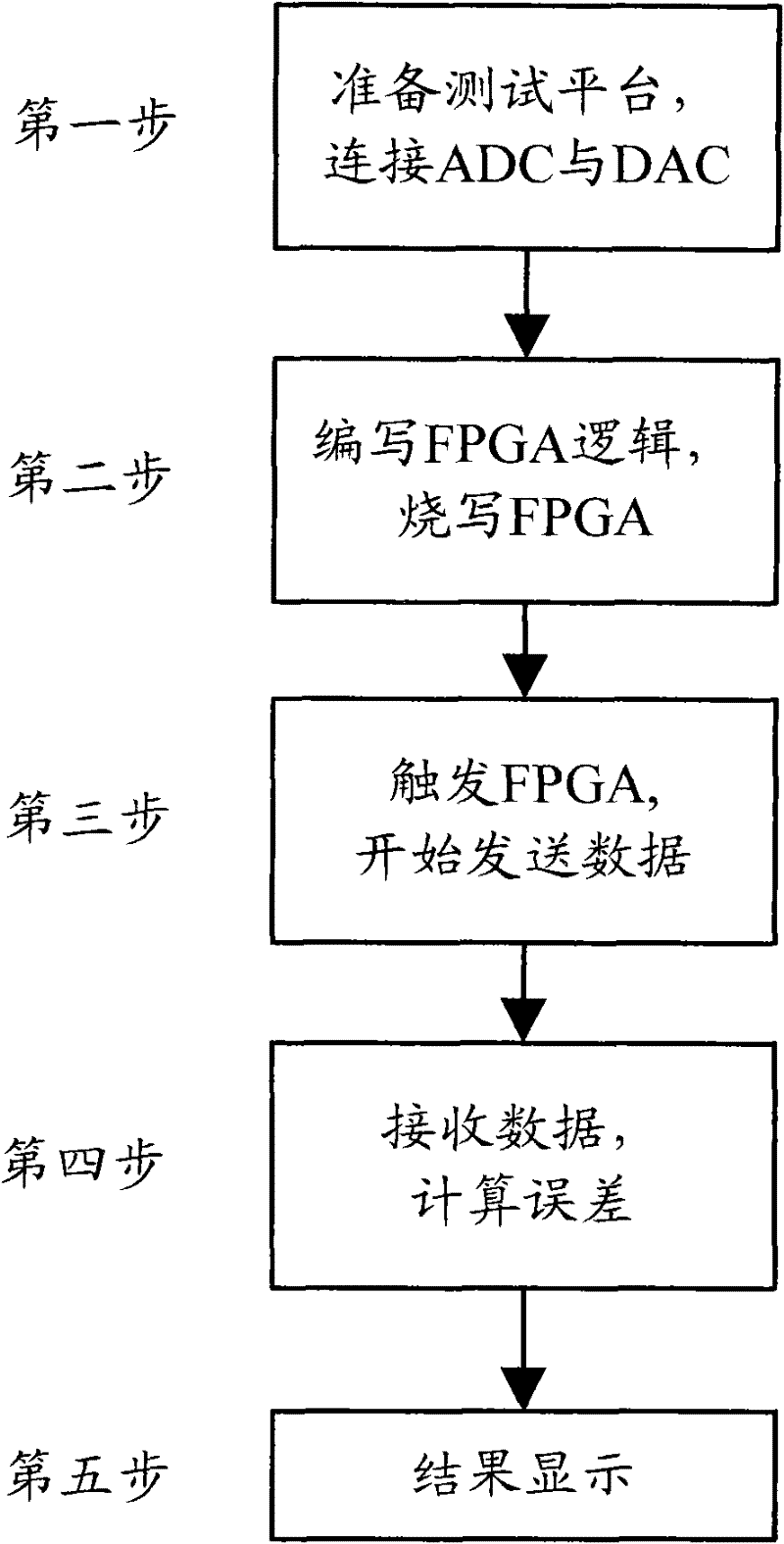

The invention relates to a circuit structure for automatically testing an analog baseband chip comprising an analog-digital converter (ADC) and a digital-analog converter (DAC). A low-voltage differential signal conversion module is connected with a low-voltage differential signal input end and a low-voltage differential signal output end of the analog baseband chip; an output end of the DAC of the analog baseband chip is connected with an input end of the ADC; the low-voltage differential signal conversion module is connected with a transmit data storage module, a receive data storage module and a transmitting and stopping control module; and the transmit data storage module and the receive data storage module are connected with an external display device via an error calculation module and a test result display module. The invention also relates to a method for automatically testing the analog baseband chip comprising the ADC and the DAC based on the circuit structure. By the circuit structure and the method for automatically testing the analog baseband chip comprising the ADC and the DAC, the testing complexity is reduced, the testing time is shortened, and the testing precision and reliability are improved; and the process is convenient and fast, the working performance is stable, and the application rage is wider.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

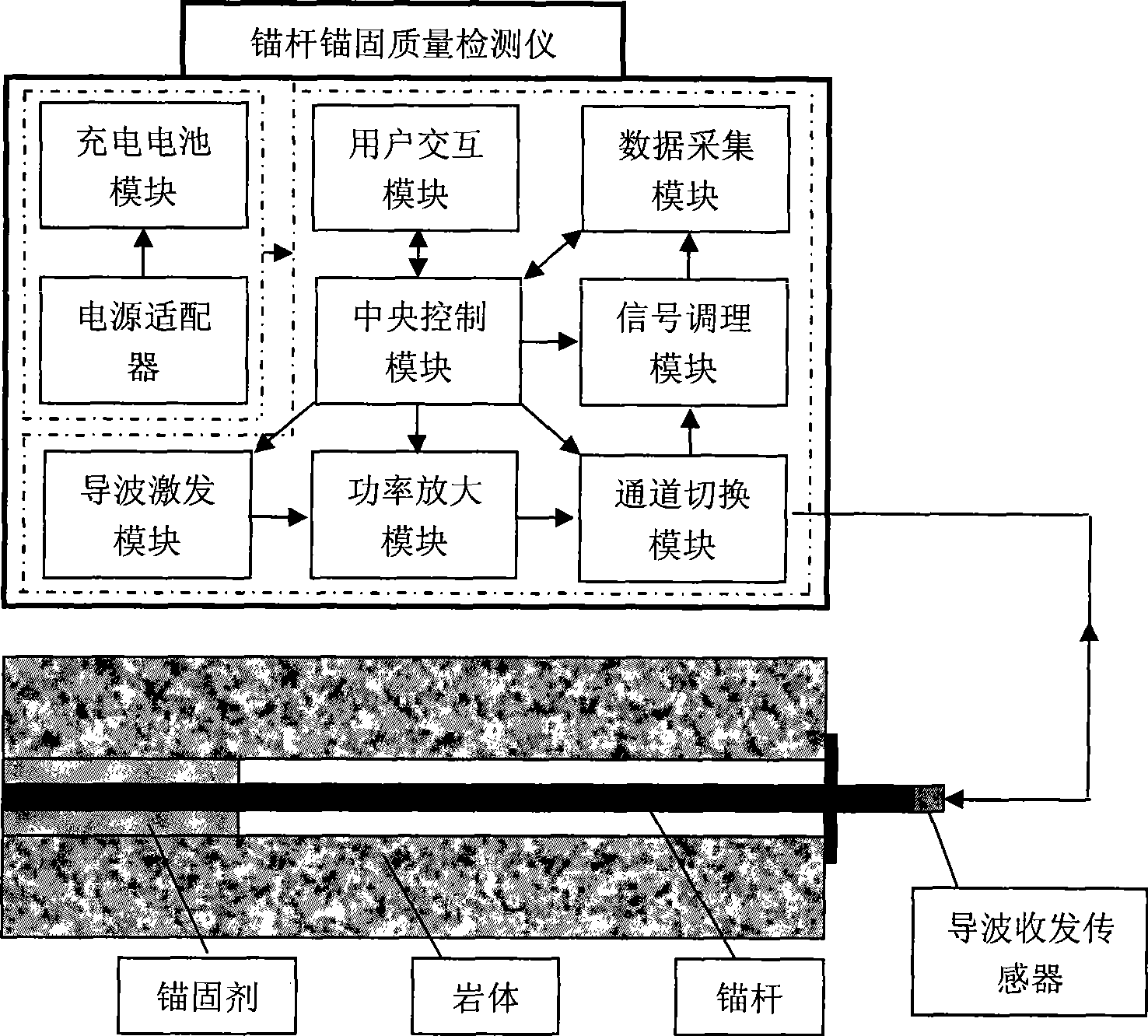

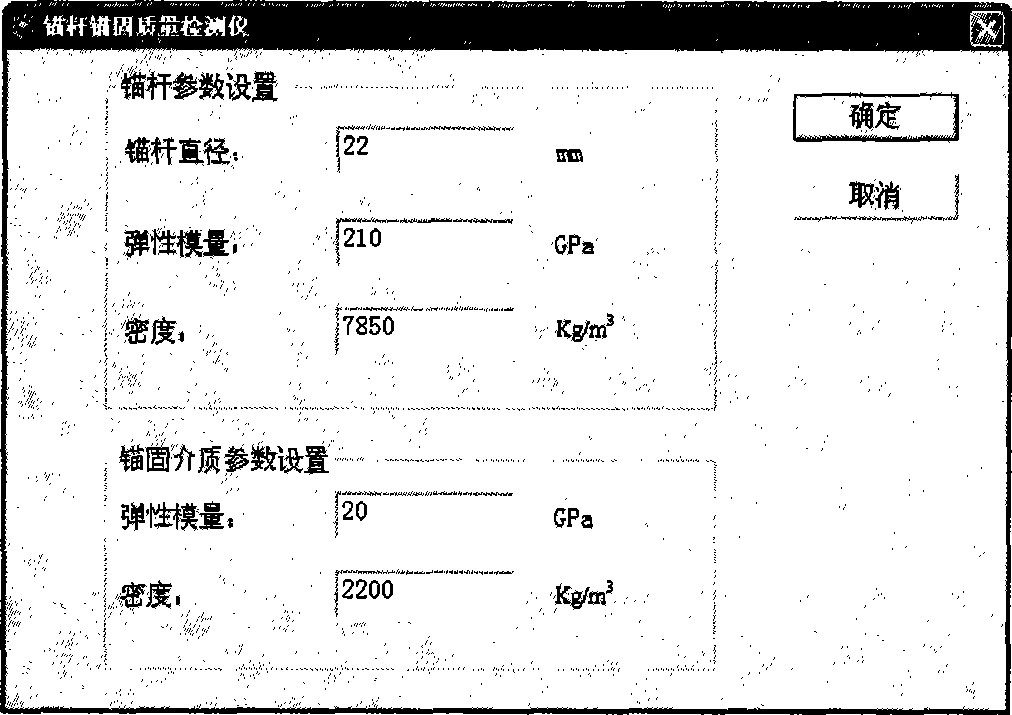

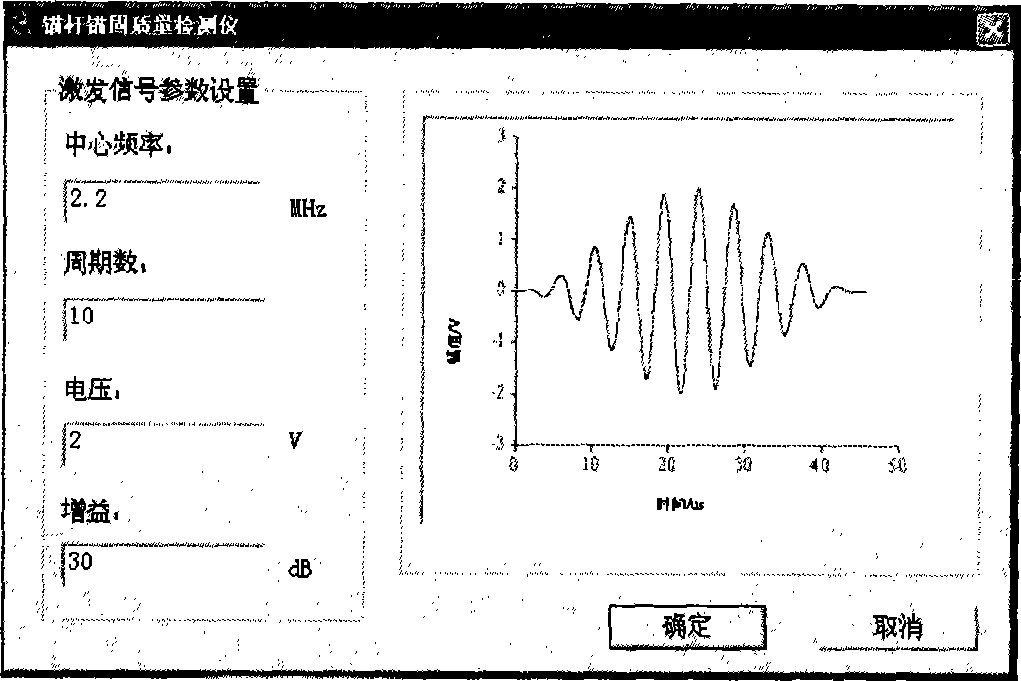

Anchor rod anchoring quality detecting instrument

InactiveCN101458232AWon't hurtQuick checkMaterial analysis using acoustic emission techniquesForce measurementDual modeData acquisition

The invention relates to an anchor rod anchoring quality detector, and belongs to the non-destructive test technical field. The detector comprises a central control module, a guided wave excitation module, a power amplification module, a channel switching module, a signal conditioning module, a data acquisition module, a user interaction module, a rechargeable battery module, a power adapter and a guided wave transceiving transducer. The detector adopts high-frequency and low-frequency guided wave dual-mode detection, and can comprehensively evaluate the anchor rod anchoring quality. The detector has simple operation, can display detection results in real time, can be manufactured into a plurality of modes such as a portable type, a vehicle-borne type, a stationary type and the like, and facilitates working personnel to be capable of rapidly detecting the anchor rod anchoring quality in practical engineering.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

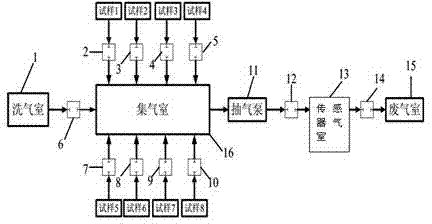

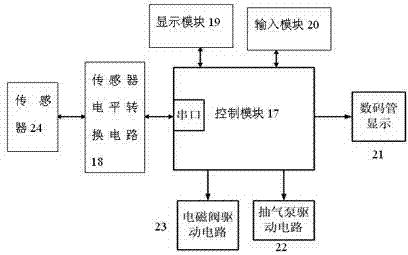

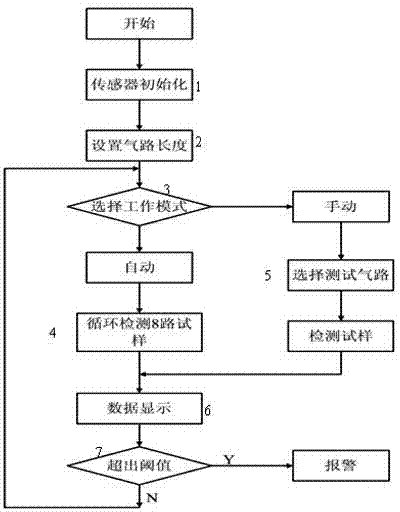

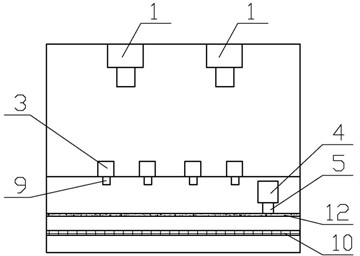

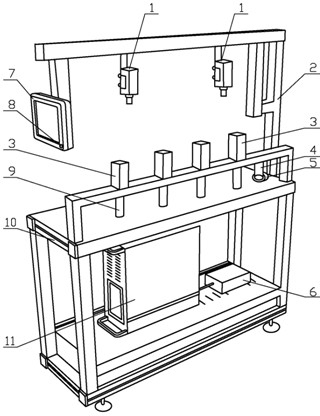

High sensitive multipath SF6 on-line leak detector and detection method thereof

ActiveCN102661834AReal-time detection contentReal-time display of test resultsColor/spectral properties measurementsFluid-tightness measurement using fluid/vacuumSolenoid valveProcess engineering

The invention discloses a high sensitive multipath SF6 on-line leak detector, comprises a gas washing chamber which has a gas outlet connected with a solenoid valve for washing gas; a gas collecting chamber which has a gas inlet connected with the solenoid valve for washing gas and a plurality of paths of samples, wherein gas path solenoid valves are arranged on the gas path between each path of samples and the gas collecting chamber; a suction pump which has a gas inlet connected with the gas outlet of the gas collecting chamber; a sensor gas chamber which has a gas inlet and a gas outlet connected respectively with solenoid valves for sensor, wherein the solenoid valve for sensor beside the gas inlet is connected with the gas outlet of the suction pump; an exhaust gas chamber which has a gas inlet connected with the solenoid valve for sensor beside the gas inlet of the sensor gas chamber; control circuits; and a sensor which is arranged inside the sensor gas chamber. The detector of the invention detects SF6 content in a real-time way and displays detection results. Multipath gas samples can be detected at the same time without switching off equipments and the paths of gas which need to be detected can be switched based on needs freely. Cleaning can be performed to the gas path of the leak detector and detection processes of different gas paths do not interfere mutually.

Owner:KUNSHAN HEZHI ELECTRICAL EQUIP

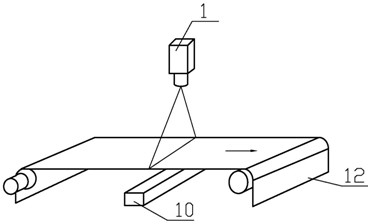

System for detecting defects of filter paper based on machine vision technology and detection method thereof

InactiveCN102323272AReal-time online stable, accurate and efficientOnline stable, accurate and efficientOptically investigating flaws/contaminationComputer printingDisplay device

The invention relates to a system for detecting defects of filter paper based on a machine vision technology and a detection method thereof. The system comprises a machine frame, a machine vision device, an industrial personal computer and defect mark printers, wherein the machine vision device comprises a light source and a plurality of high-speed cameras; the industrial personal computer comprises a central microprocessor and a display of built-in embedded image processing software; the defect mark printer comprises an encoder and a plurality of defect mark printers; according to characteristics of a product to be detected, noises are eliminated through smoothing filtering by using a two-dimensional zero-mean discrete Gaussian function, and based on a roof edge subpixel positioning algorithm, the defects of the image of the product are recognized; the characteristics of materials to be detected are picked up by the high-speed cameras; and the defect mark printers are controlled by the central microprocessor. By the system and the detection method, the defects of the filter paper can be detected stably, accurately and efficiently online in real time; coordinates are automatically positioned to print defect marks; and the system can alarm automatically and display detection results in real time.

Owner:HEFEI WHEREVER ELECTRONICS TECH +1

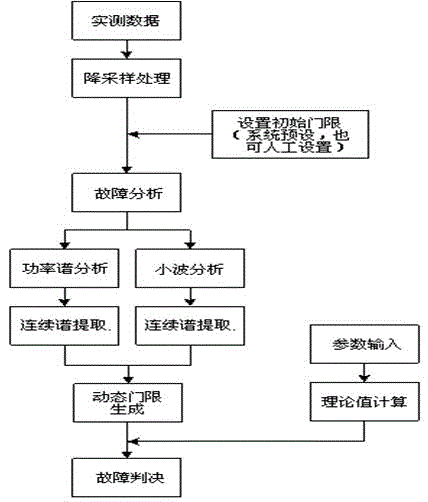

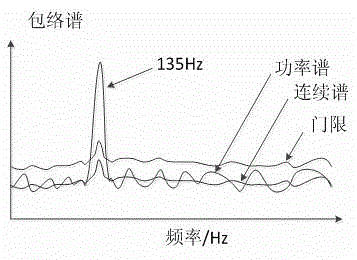

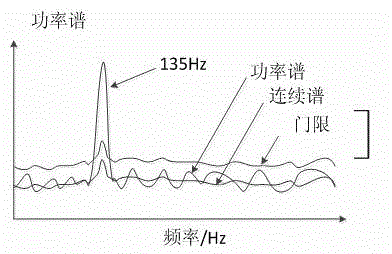

Bearing fault detection method

InactiveCN104614182AImprove efficiency and accuracyRefined detectionMachine bearings testingWavelet transformBearing fault detection

A bearing fault detection method includes six steps of collecting signals, obtaining the fault character frequency, conducting analysis, conducting filtering, extracting thresholds and distinguishing faults. The method has the advantages that the characteristic result of an envelope spectrum is extracted by comprehensively using a power spectrum and wavelet conversion, whether a line spectrum in the bearing detection process is an interference spectrum or a fault line spectrum is judged, and the bearing detection efficiency and accuracy are effectively improved. The method is simple, small in calculation amount and easy to achieve, the detection result can be displayed in a computer in real time, and the automated and intelligent bearing detection is completely achieved.

Owner:DALIAN SCI TEST & CONTROL TECH INST

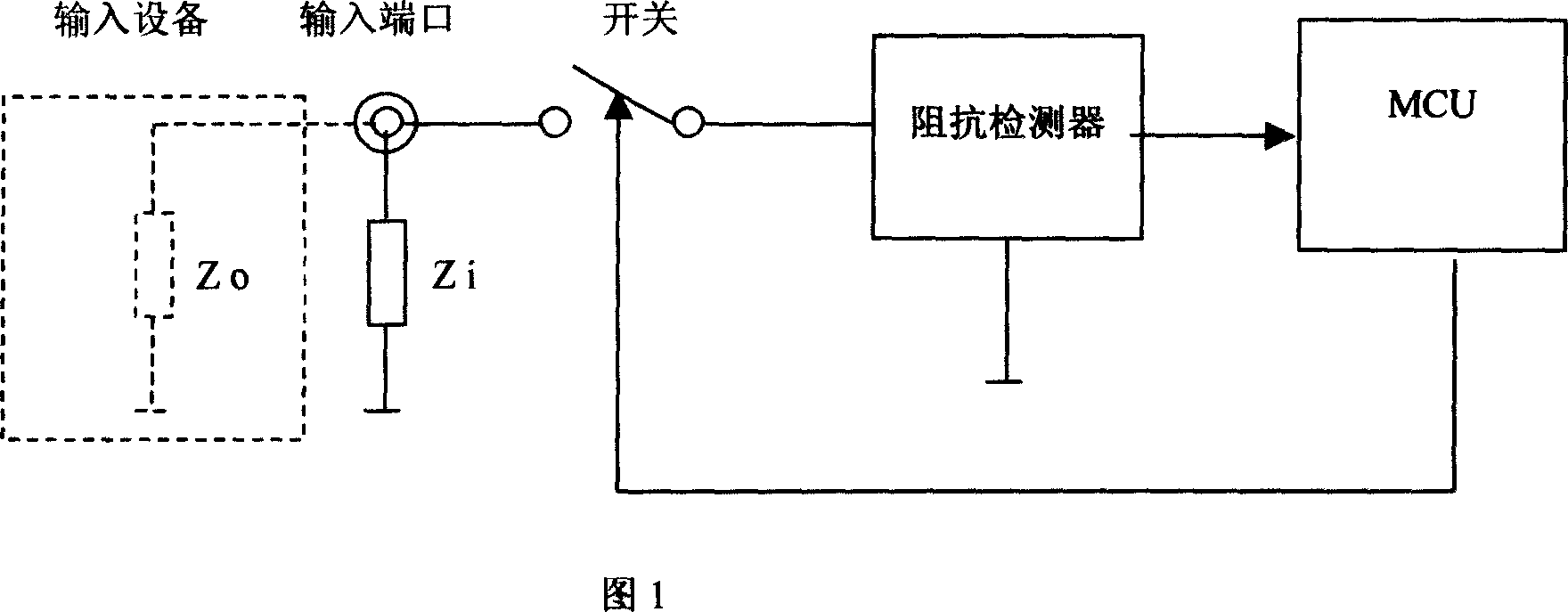

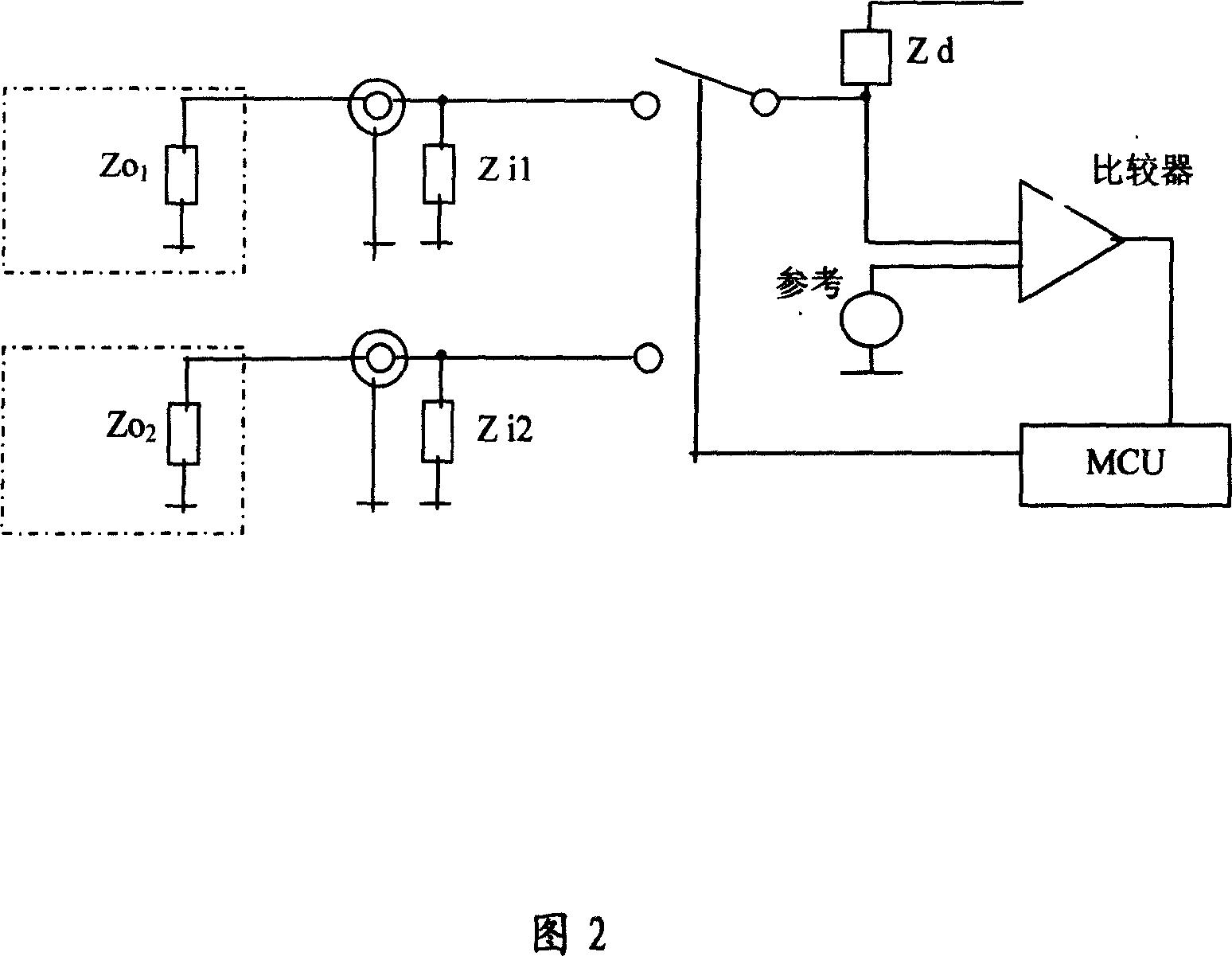

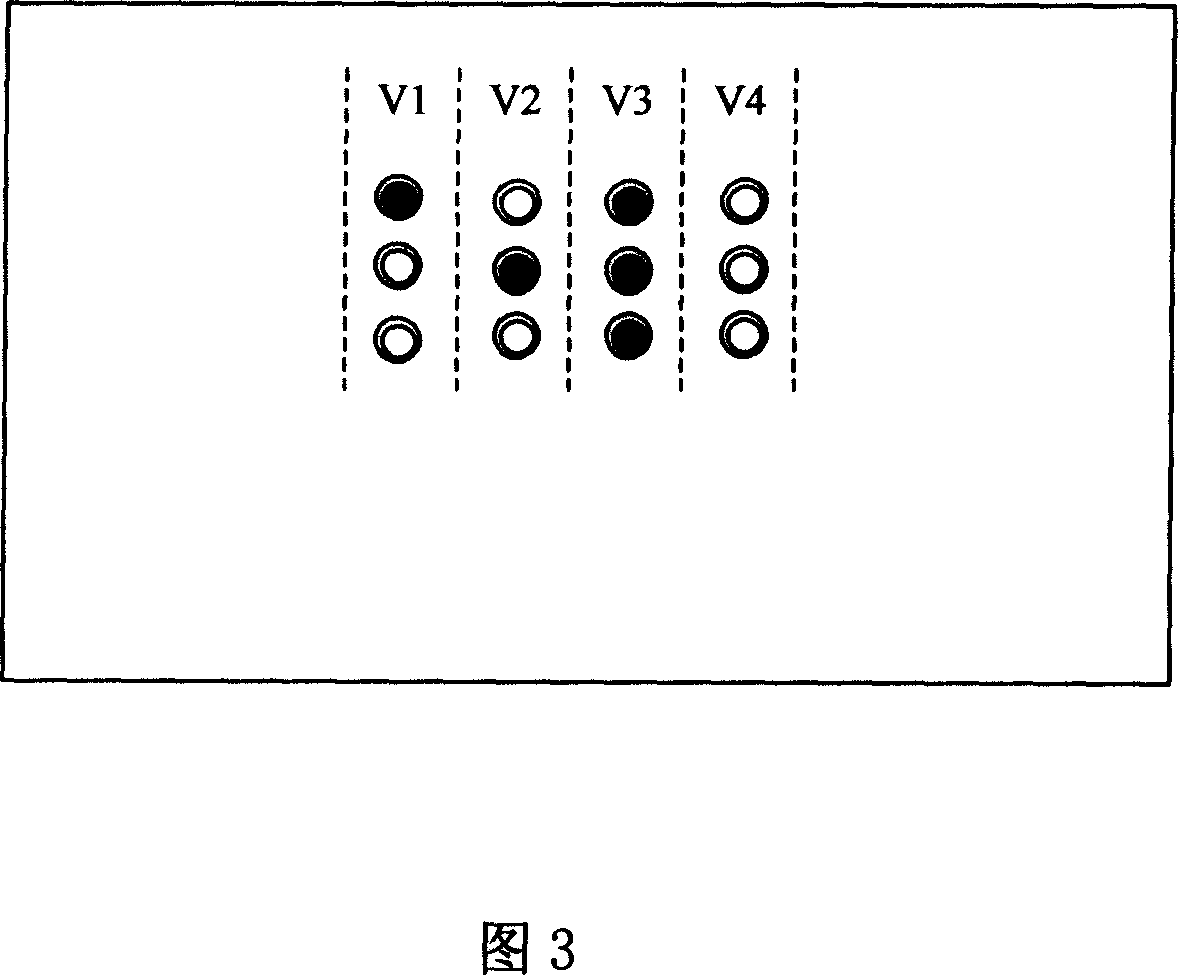

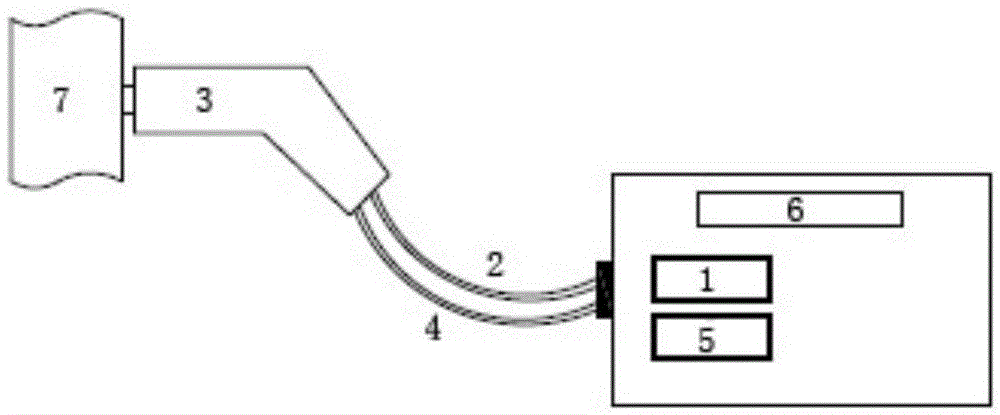

Method and apparatus for inspecting connection status between display device and peripheral equipment

ActiveCN101074976AReal-time display of test resultsImprove the display effectElectrical testingElectric digital data processingDisplay deviceReal time display

A device used for detecting connection state between display unit and externally connected unit consists of input port of display unit, microprocessor MCU and impedance detector connected with said input port. It is featured as using said impedance detector to detect impedance value of said input port and using said MCU to judge connection state between display unit and externally connected unit according to detected impedance value.

Owner:SHENZHEN TCL NEW-TECH CO LTD

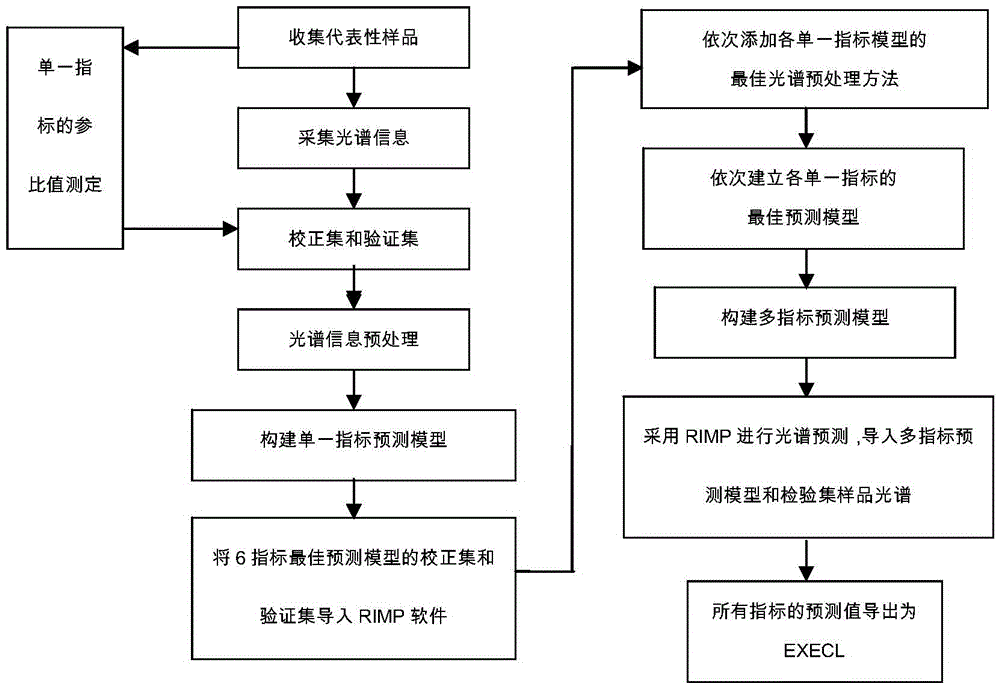

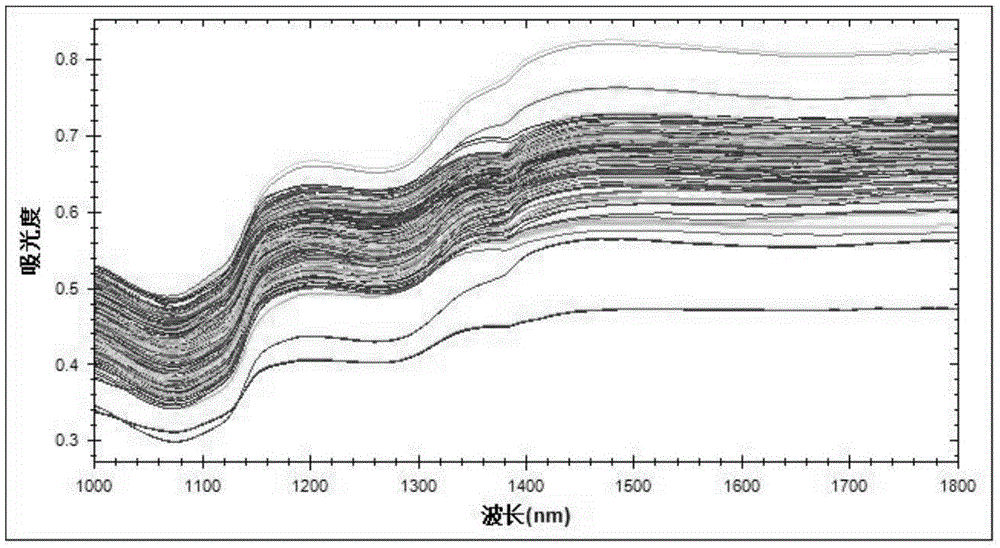

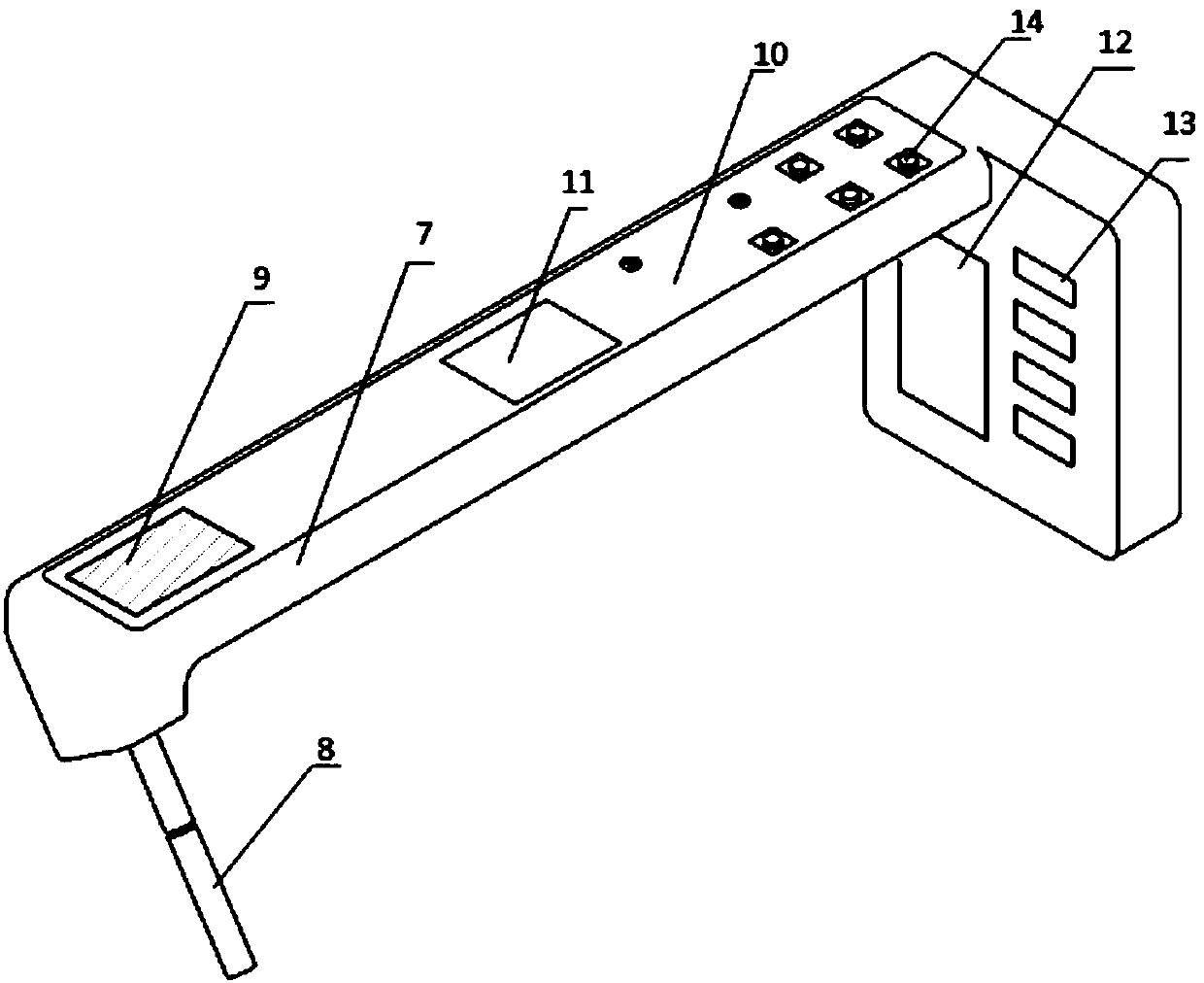

A multi-index rapid nondestructive synchronous detection method for fresh beef

The invention relates to a multi-index rapid nondestructive synchronous detection method for fresh beef. The method is based on multi-index detection of contents of cholesterol, water, fat and protein, shear force and retention ability of the fresh beef by means of a portable near-infrared spectrograph. Compared with current national standard methods in China and other applying methods of desktop near-infrared spectrographs, the method is characterized by being simple, rapid, efficient, accurate and capable of synchronous multi-index detection. The method has no limit on sample dimension and shapes. Samples to be detected are free of any destructive pretreatment, thus achieving nondestructive detection and saving a cost. A microprocessor comprising system programs is high in degree of intellectualization. Detection and analysis are completed automatically, and a detection result is displayed in real time. Special training for operators is not needed. The method is simple and convenient to operate and can be applied for online detection.

Owner:CHINA MEAT RES CENT

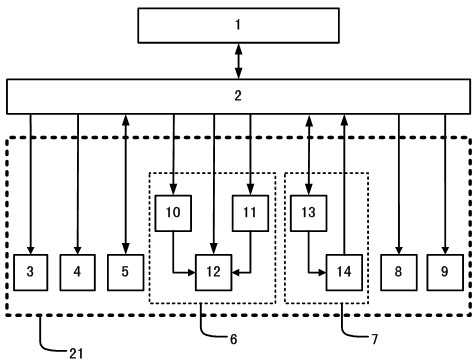

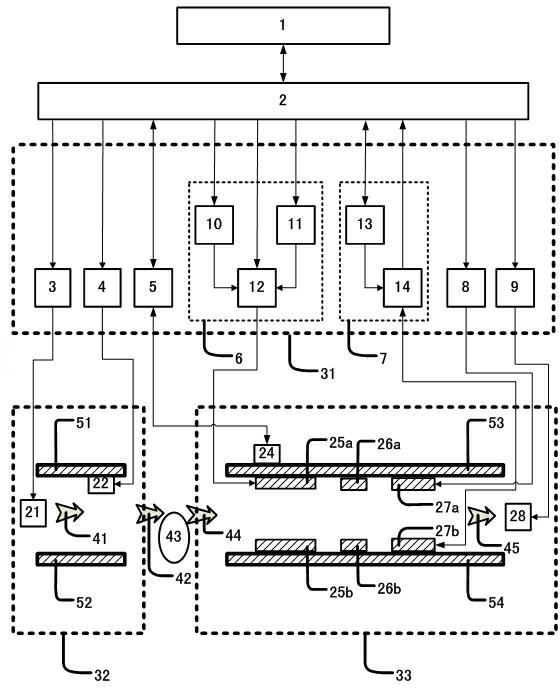

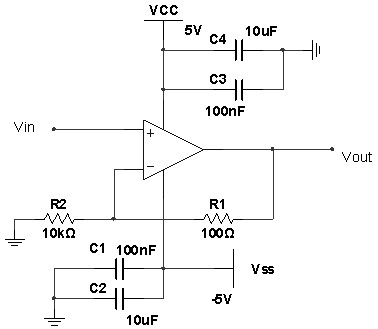

Miniature measurement and control system fit for high-field asymmetric waveform transference tube

InactiveCN102636555AReduce noiseUltra-Low Input Bias CurrentMaterial analysis by electric/magnetic meansLow noiseControl system

The invention discloses a miniature measurement and control system fit for a high-field asymmetric waveform transference tube. The system comprises a man-machine interaction module, an upper computer system and a measurement and control circuit module, wherein the measurement and control circuit module comprises a plurality of sub-circuit modules; an operator sends an operation command and observes a detection result through a friendly instrument operation interface provided by the upper computer system and the man-machine interaction module; the upper computer system is connected with the sub-circuit modules in the measurement and control circuit module; and the sub-circuit modules are connected with corresponding components in the high-field asymmetric waveform transference tube to generate measuring signals necessary for detecting substance ingredients of the high-field asymmetric waveform transference tube and detect a signal output by the high-field asymmetric waveform transference tube at high precision. The miniature measurement and control system provided by the invention is fit for high-field asymmetric waveform transference tubes with different sizes and manufactured by various techniques, and the system has the advantages of low noise, high integration degree, good reliability and anti-interference capability, and quick and simple operation, and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

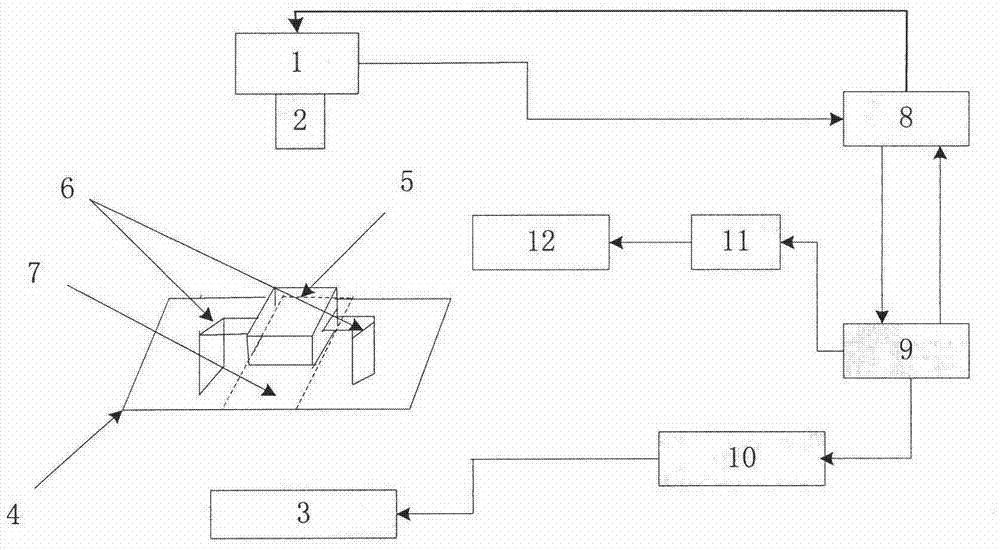

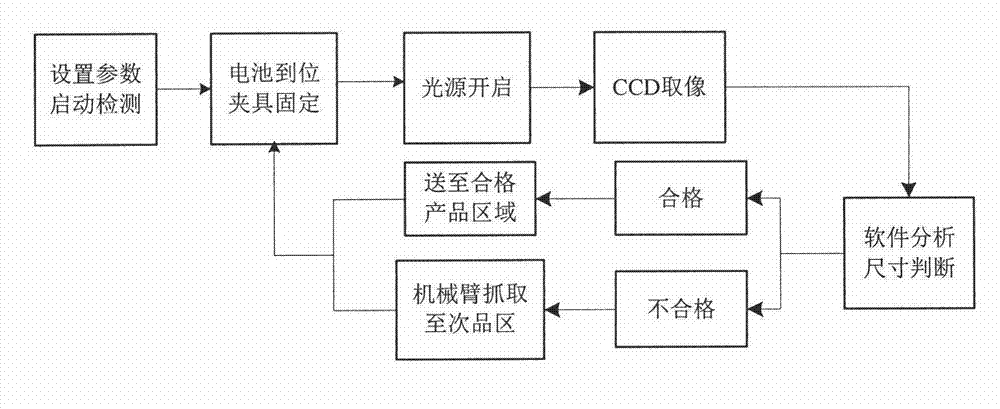

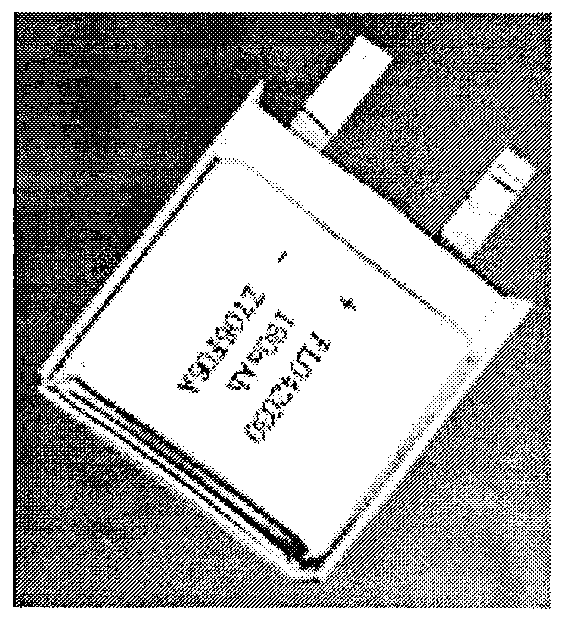

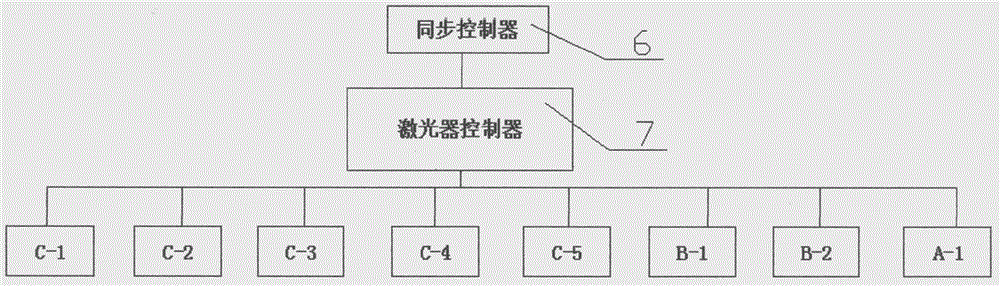

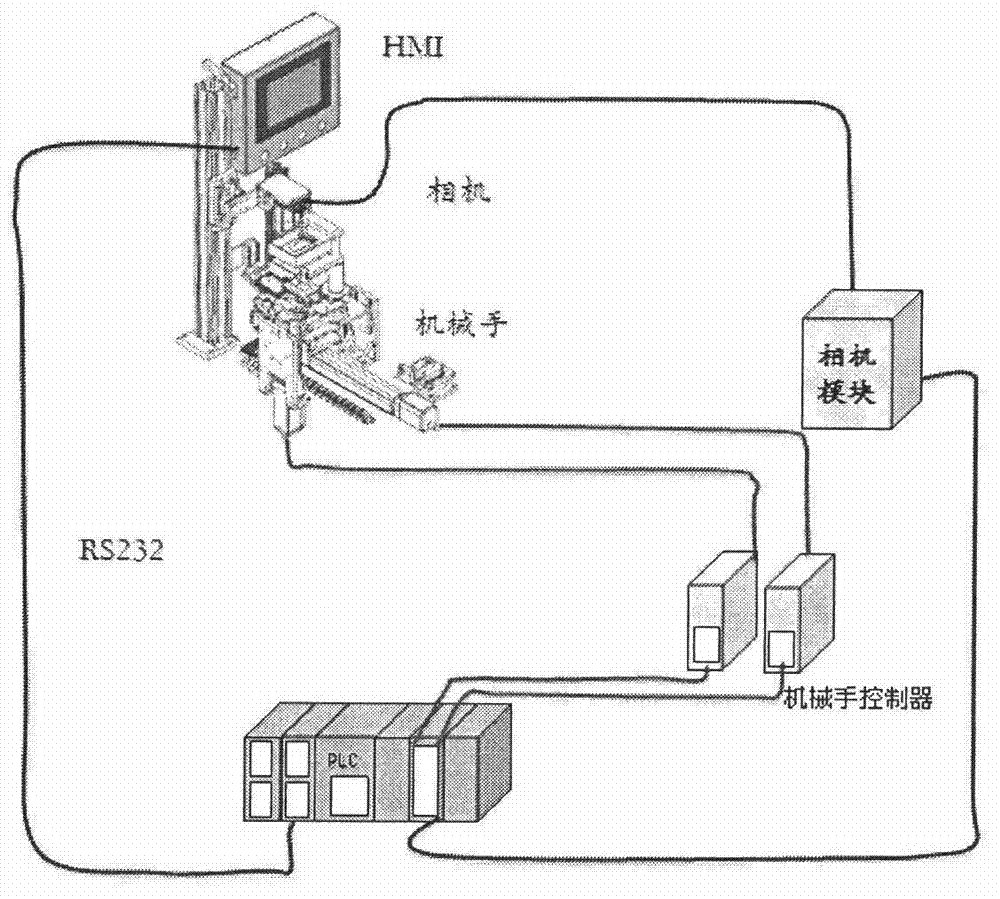

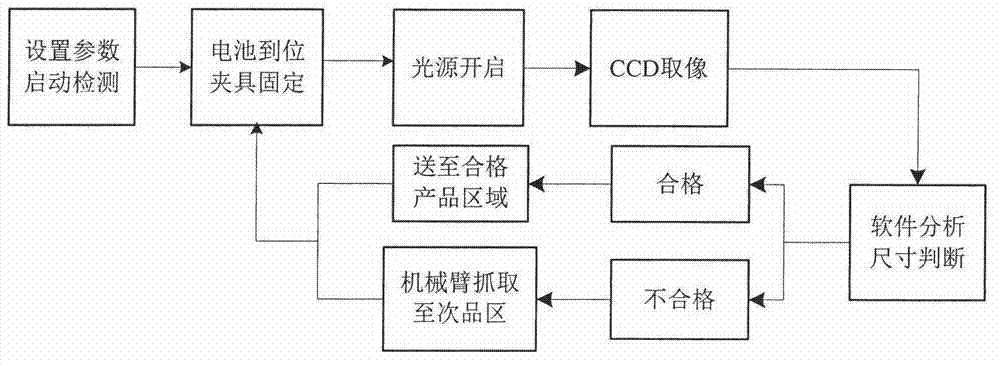

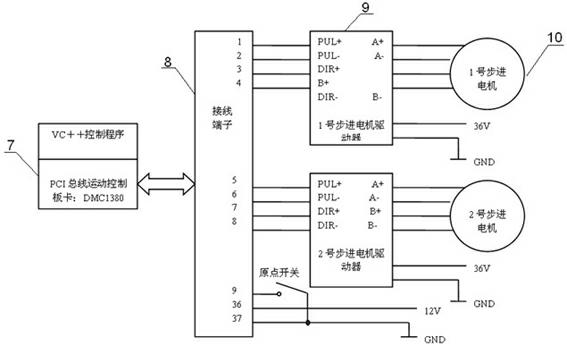

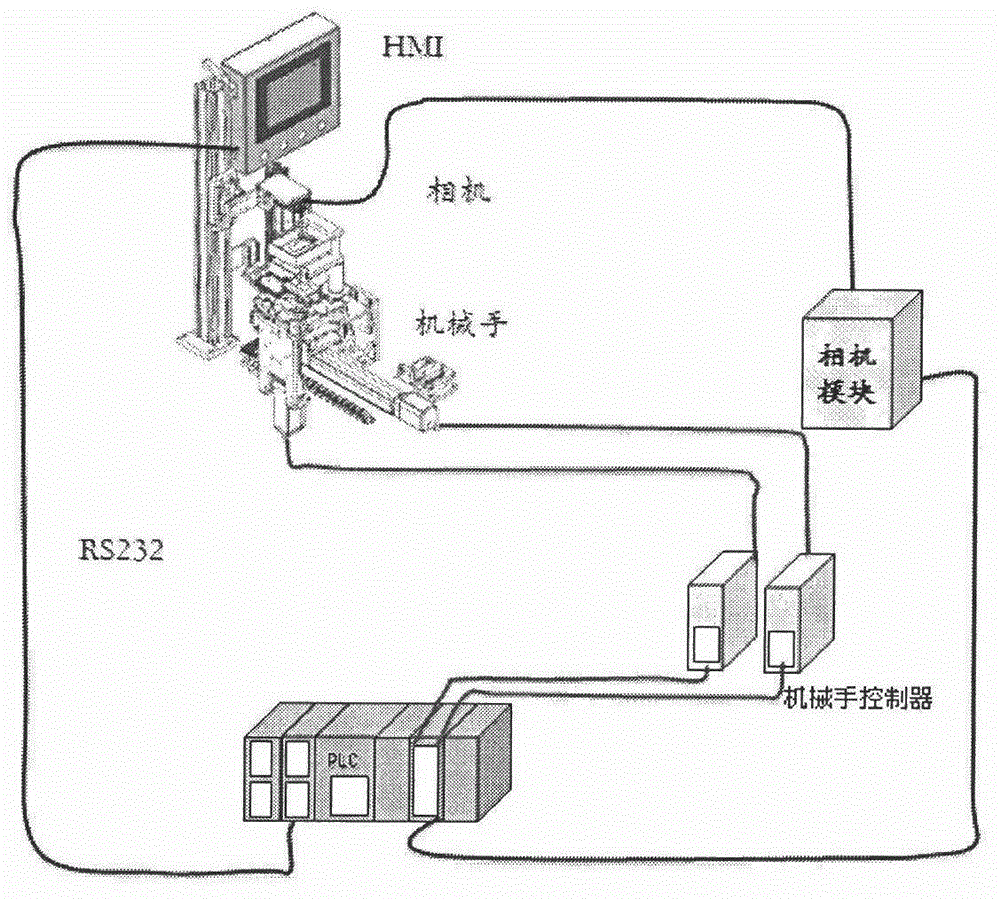

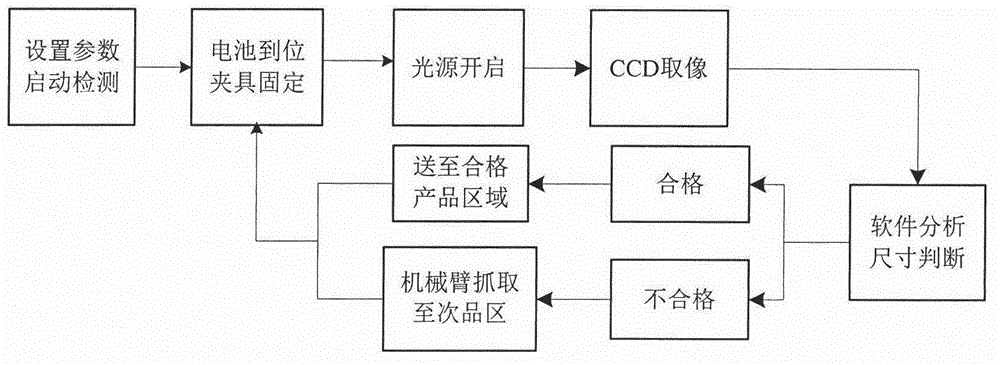

Automatic detection method of battery positive-negative electrode lug terminal length

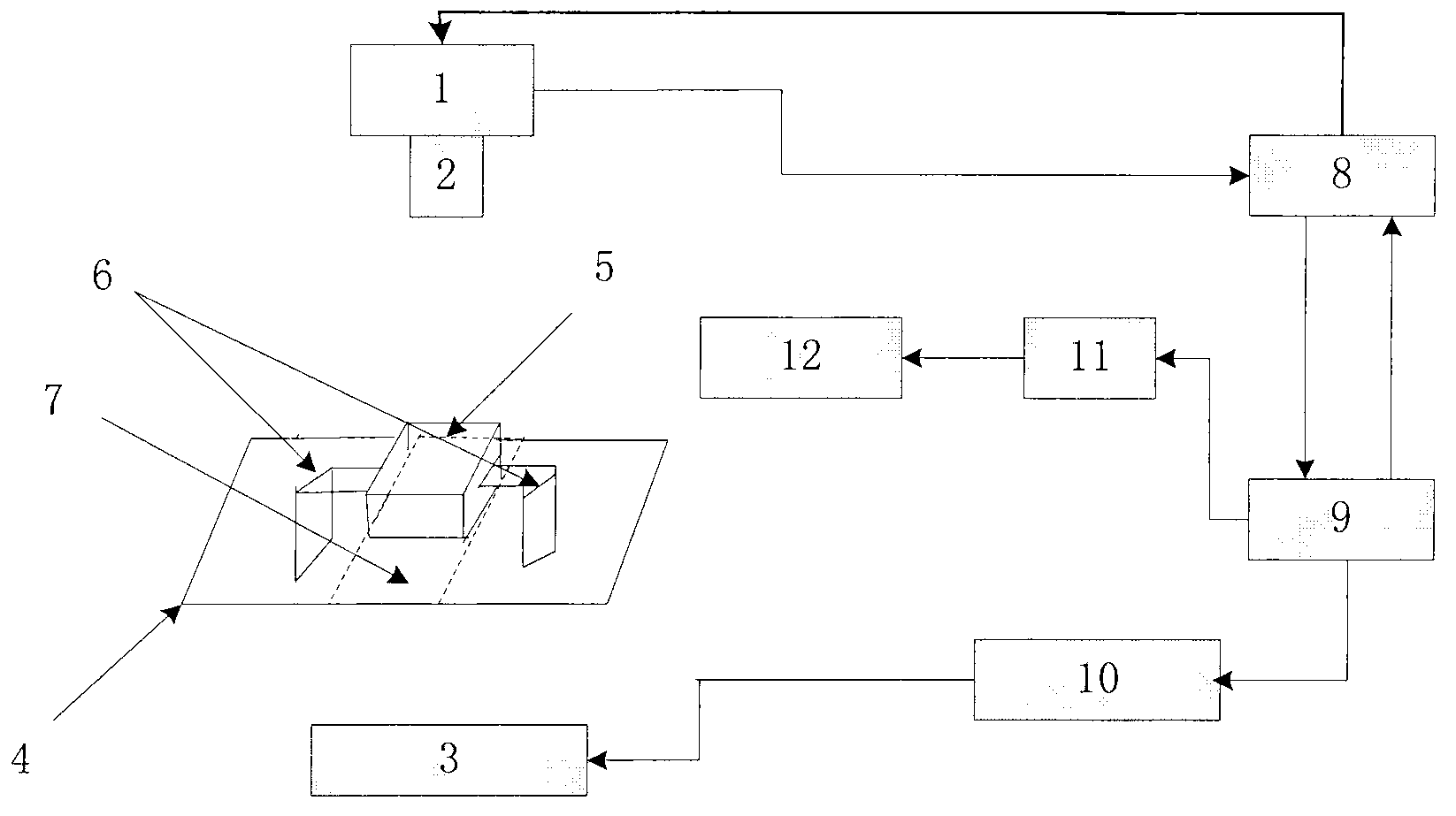

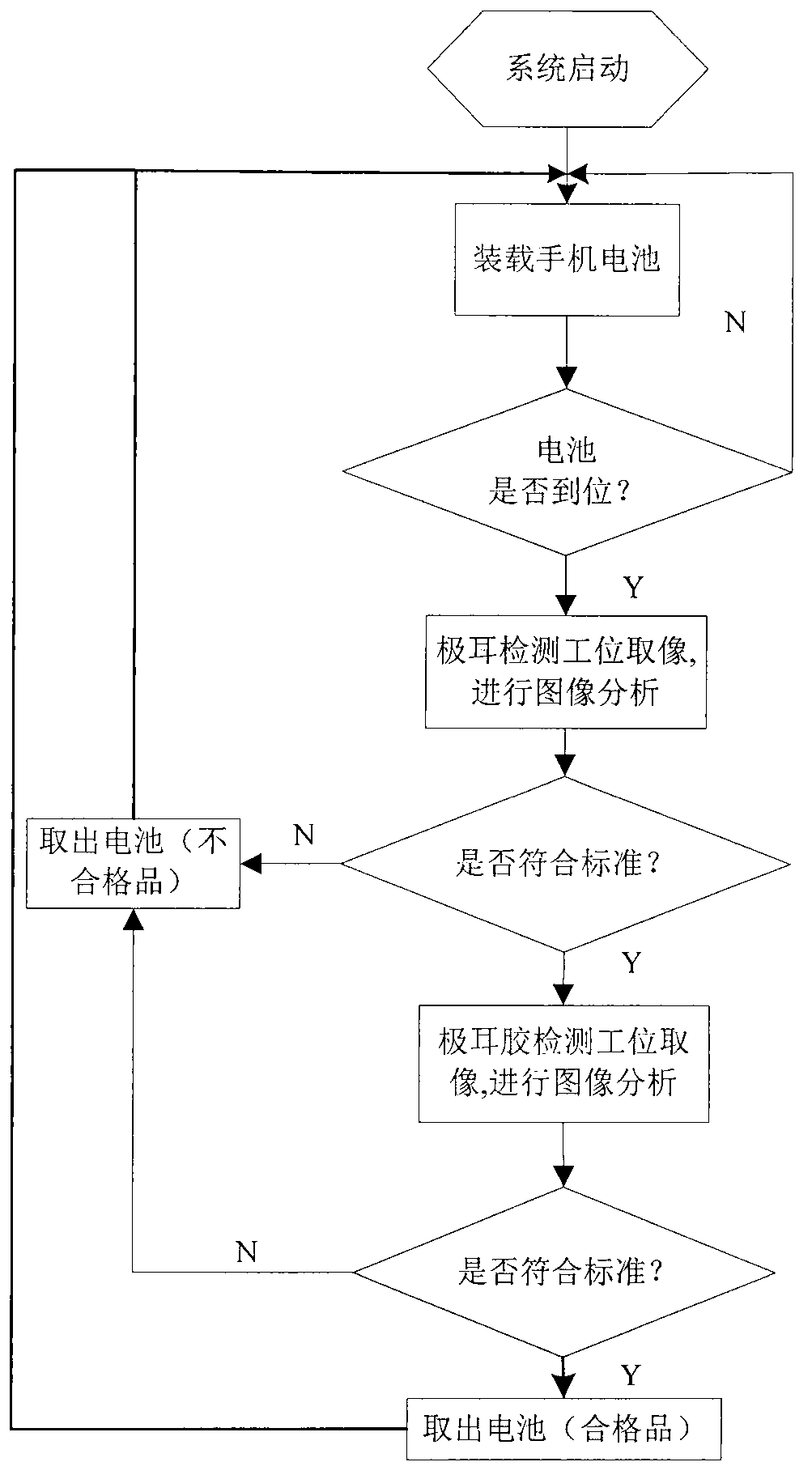

ActiveCN103196373AStable, accurate and efficient size automatic detectionRealization of size automatic detectionUsing optical meansImaging processingEngineering

The invention discloses an automatic detection method of battery positive-negative electrode lug terminal length. A detection system comprises an image processing unit, a motion control unit, a real-time monitoring unit and an upper computer. The image processing unit conducts software processing analysis on collected images and conducts detection on electrode lug size. A bottom datum line I8, a line segment I4, a line segment I5, a line segment I6, and a line segment I7 are found through an image identifying method. The top point R1 of a positive electrode lug and the top point R2 of a negative electrode lug are respectively determined through an intersection point of the line segment I4, the line segment I5, the line segment I6, and the line segment I7, then the distance D1from the R1 to the bottom datum line I8 and the distance D2 from the R2 to the bottom datum line I8 are respectively calculated, the values of the D1 and the D2 are the length of the positive electrode lug terminal and the length of the negative electrode lug terminal. The automatic detection method of the battery positive-negative electrode lug terminal length can achieve fast and accurate automatic detection of the length of the battery positive electrode lug terminal and the length of the battery negative electrode lug terminal.

Owner:无锡埃姆维工业控制设备有限公司

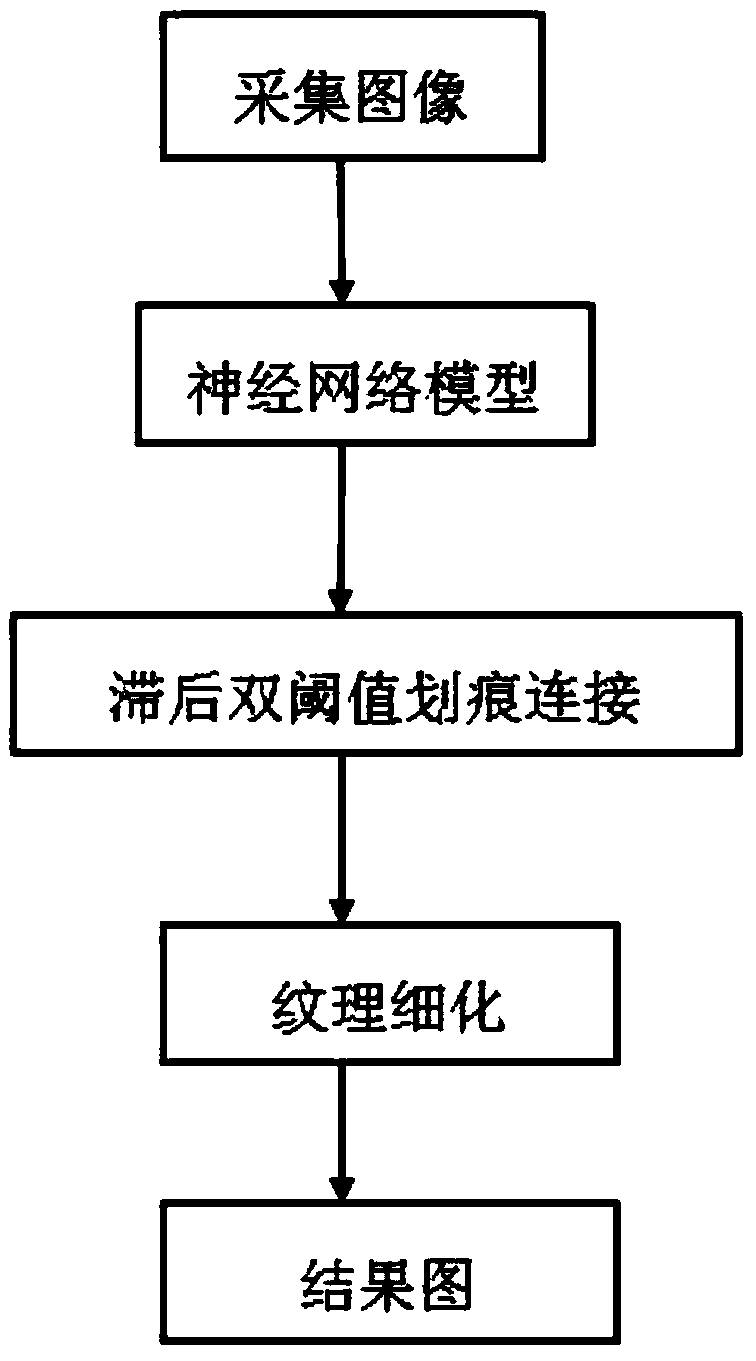

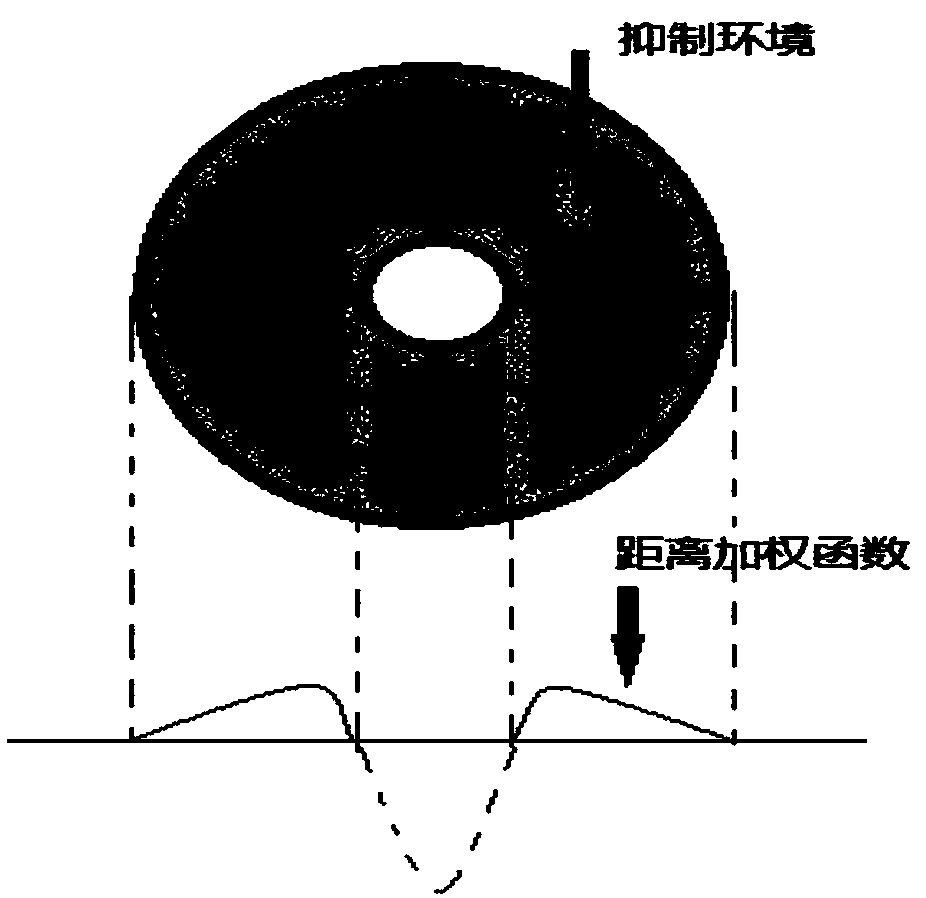

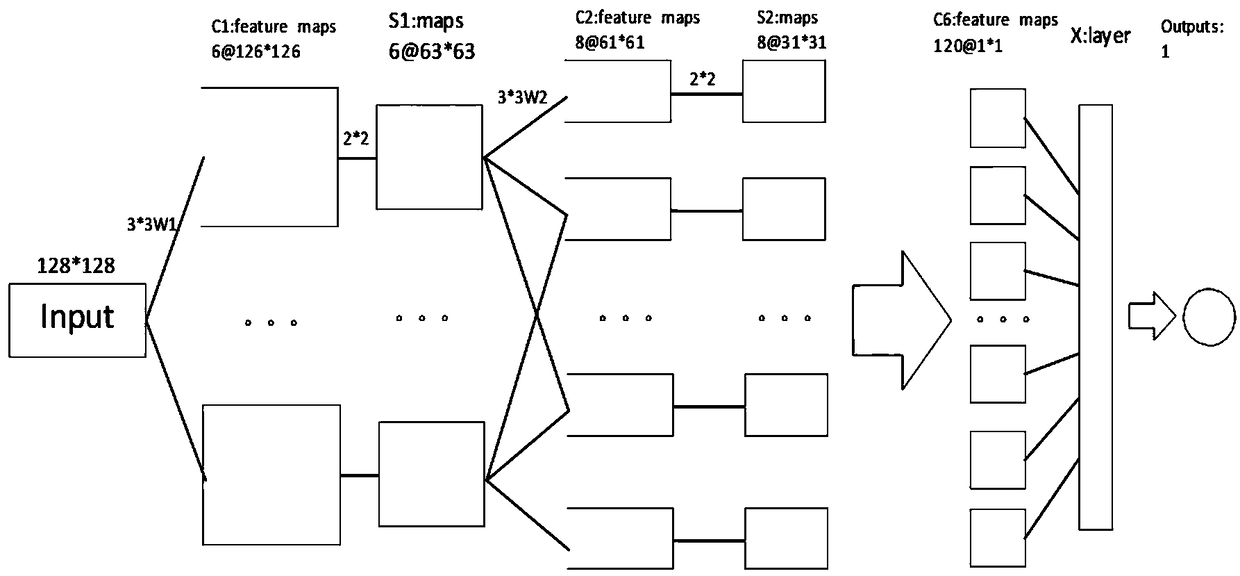

Product surface scratch detecting method based on machine vision

ActiveCN109060838AEfficient detectionAccurate detectionMaterial analysis by optical meansMachine visionDouble threshold

The invention discloses a product surface scratch detecting method based on machine vision, and relates to the technical field of machine vision defect detection. The product surface scratch detectingmethod specifically comprises the steps that signals are received, and image information is collected; texture inhibition is conducted on images through a convolutional neural network, nonclassical feeling wild inhibition is conducted on the collected images first, then the inhibited images are input into the trained convolutional neural network to be subjected to texture estimation, and at lastthe images are subjected to dynamic iteration inhibition to initially obtain scratch images; lagged double-threshold scratch connection is conducted, breakage scratches in a small range are connected,a high threshold and a low threshold are adopted to conduct binaryzation on the images, and the edges of the images are connected with the high threshold as the basis and the low threshold as the compensation; and the scratch images are thinned. According to the product surface scratch detecting method, mobile phone partition images are quickly collected in real time and are subjected to a seriesof treatment, so that surface scratches are efficiently and accurately detected, and detecting results are displayed in real time.

Owner:SANGU XIAMEN TECH CO LTD

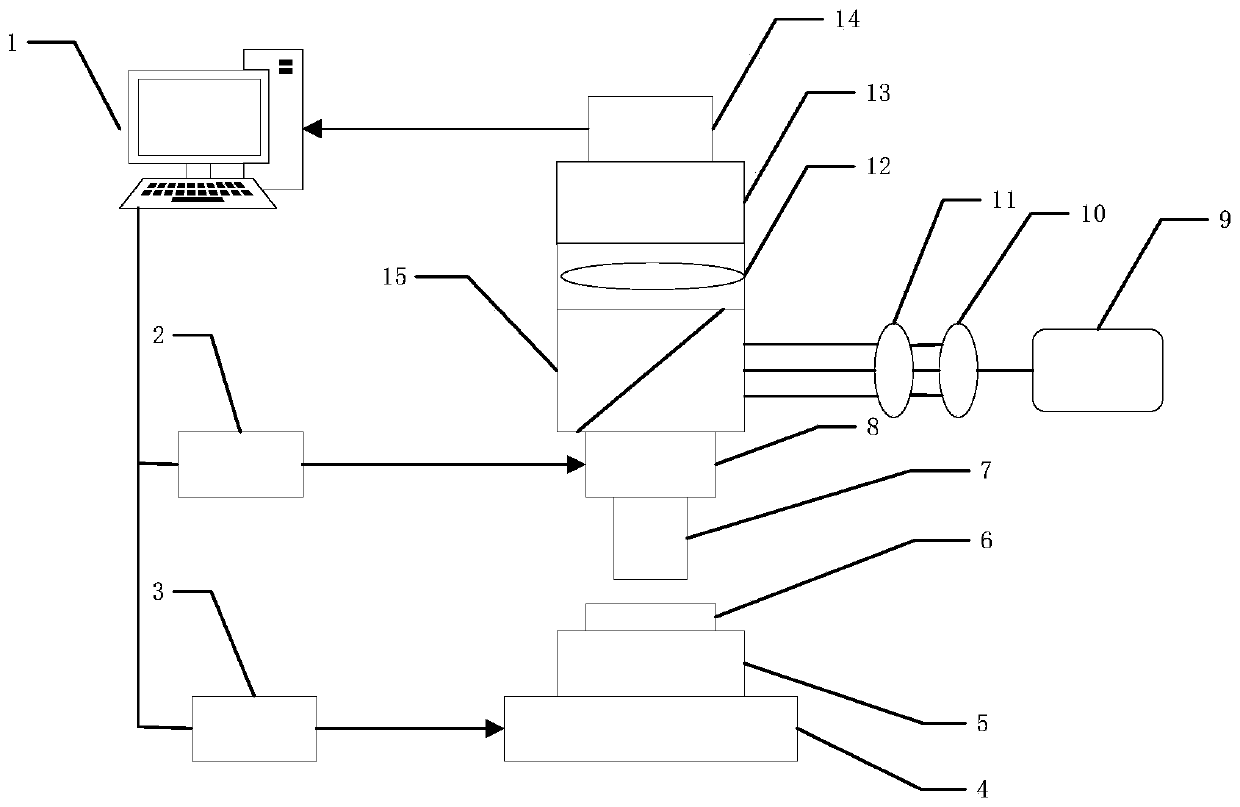

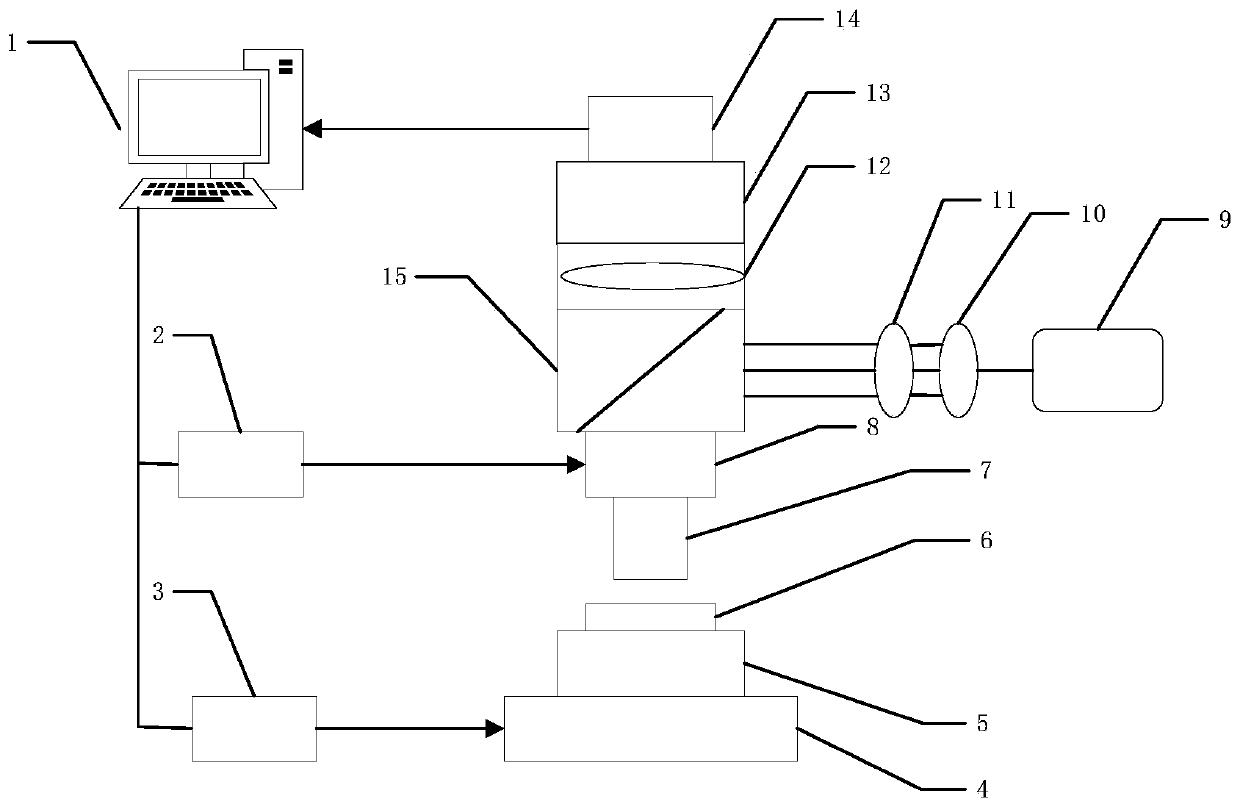

Super-resolution defect detecting device and detecting method based on super-oscillation lens

ActiveCN110031478ARealize defect detection functionReal-time online monitoringOptically investigating flaws/contaminationLithographic artistLaser light

The invention discloses a super-resolution defect detecting device and detecting method based on a super-oscillation lens. A workpiece table, a vacuum adsorption device, a substrate, a semi-transparent and semi-reflective mirror group, a laser light source, a collimating lens, an objective lens, a CCD, a piezoelectric motor, a linear motor, an upper computer and the like are used, so that a collimated laser light is irradiated to the semi-transparent and semi-reflective mirror group; the semi-transparent and semi-reflective mirror group reflects the laser light onto the substrate first; then the light reflected from the surface of the substrate passes through the semi-transparent and semi-reflective mirror, and then converges on the CCD through a specially optimized super-oscillation lens;and the process of automatic focusing is completed by using an image acquired by the CCD and a program in the host computer, and finally the defect detection of the substrate below 100 nm is realized. The super-resolution defect detecting device and detecting method based on the super-oscillation lens can be used for the detection of substrate defects in a lithography machine, and improves the yield of the lithography machine in actual industrial production.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

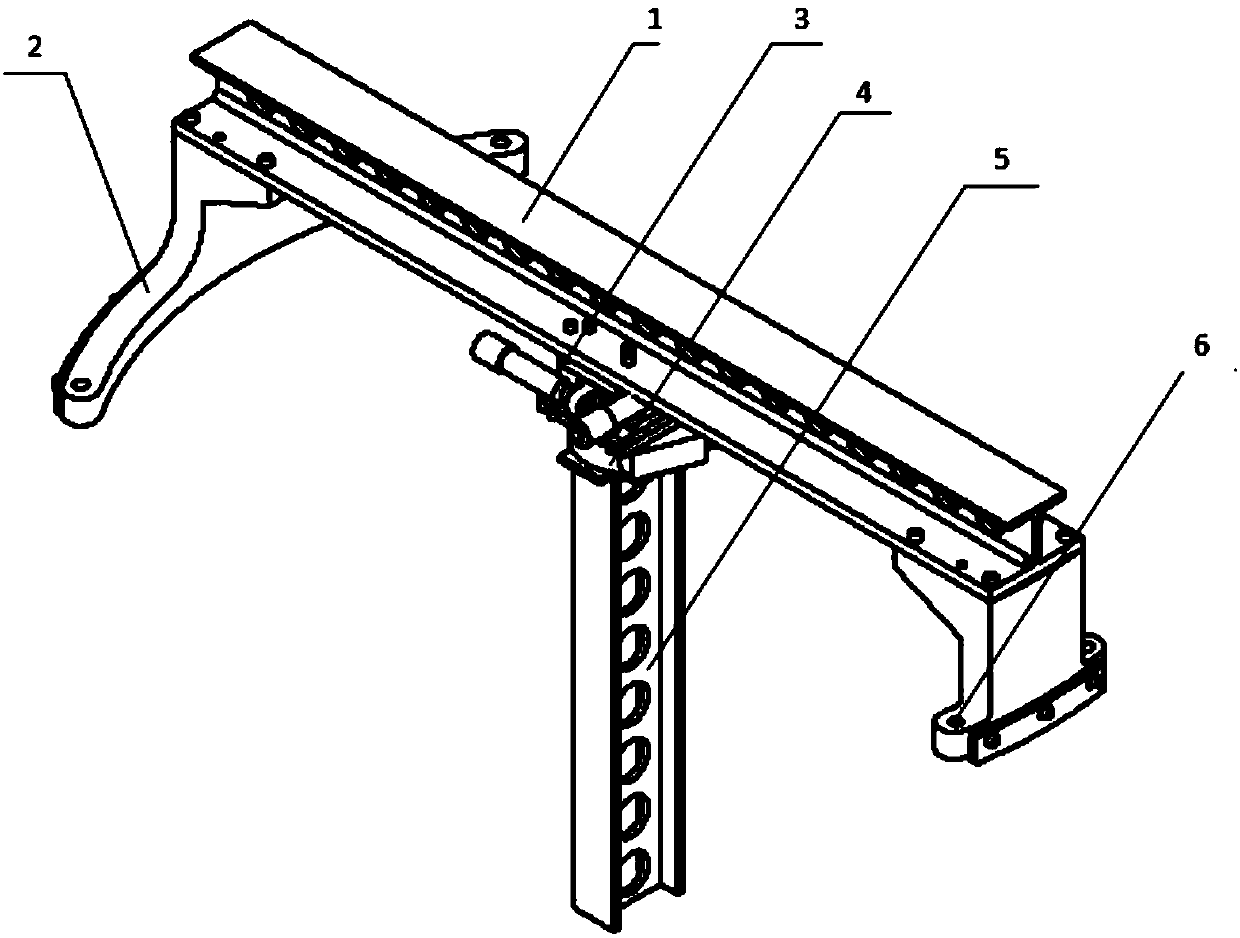

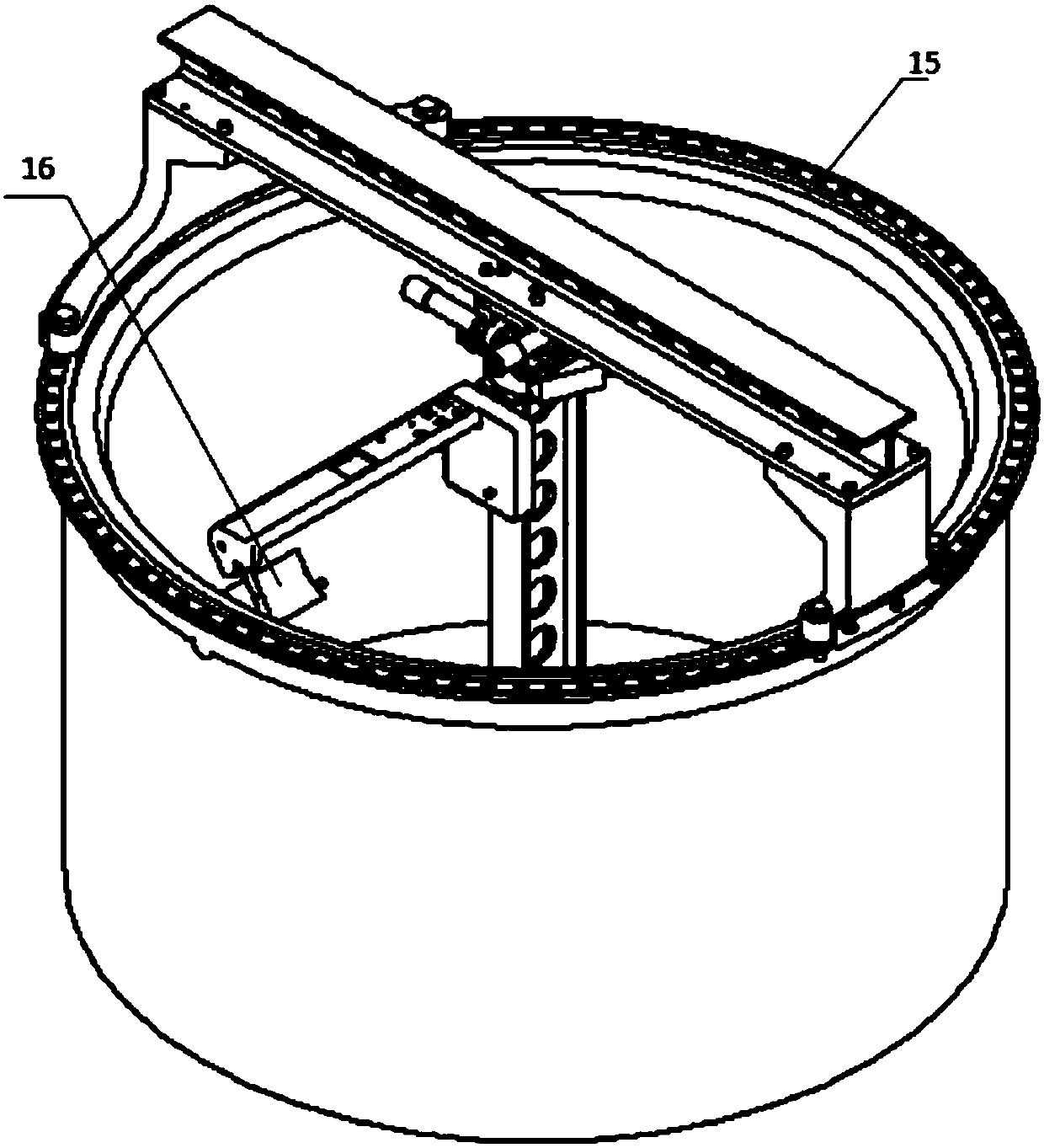

Intelligent detection device and method for compressor stator guide vane setting angle

ActiveCN109780976AHigh measurement accuracyImprove efficiencyAngles/taper measurementsEngineeringData recording

The invention relates to an intelligent detection device and method for a compressor stator guide vane setting angle. A measuring and positioning tool is composed of a tool cross beam (1), supportingbases (2), a two-dimensional sliding table (3), a high-precision rotary table (4), a depth shaft (5) and positioning pins (6), wherein the two-dimensional sliding table (3) and the high-precision rotary table (4) are sequentially installed on the lower end face of the middle of the tool cross beam (1), and the depth shaft (5) is fixed to the high-precision rotary table (4); the two supporting bases (2) are located on the two sides of the tool cross beam (1) respectively, the positioning pins (6) are arranged on the supporting bases (2), and the measuring and positioning tool is fixedly placedon a to-be-detected compressor case (15) through the positioning pins (6). Detection results can be displayed in real time, detection result data storage and export functions are provided, and the defects of manual misreading, complex data recording and the like are overcome; the detection method is high in measurement precision, high in efficiency and convenient to use.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC +1

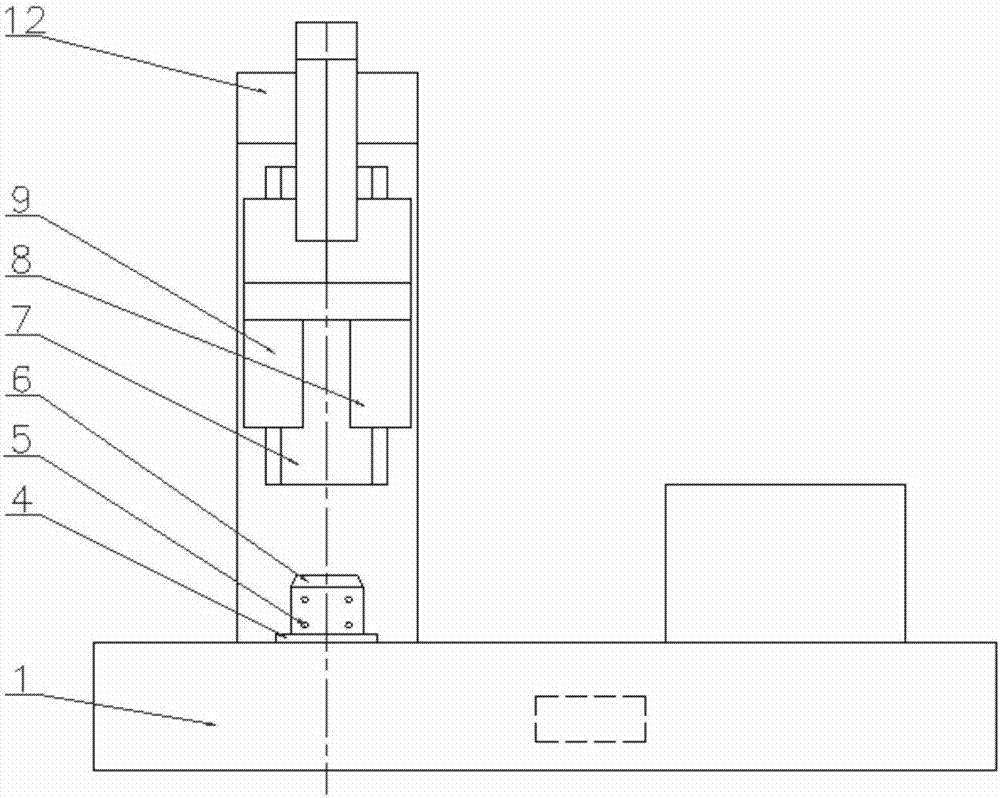

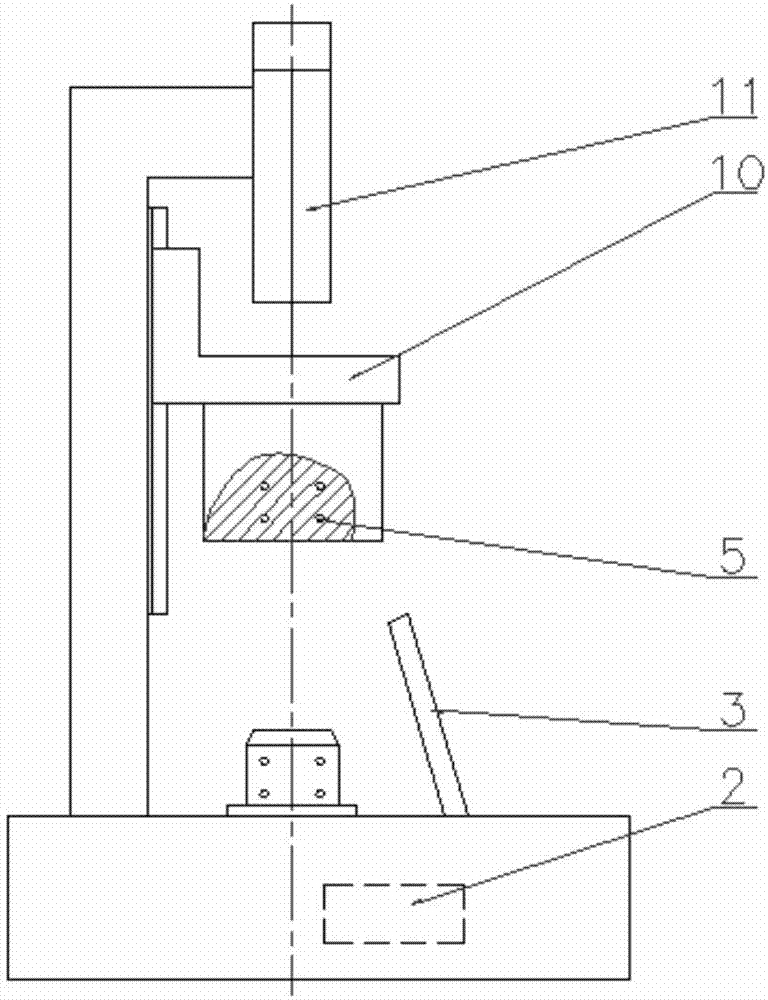

Flying drone engine's sleeving size and geometrical error detection device

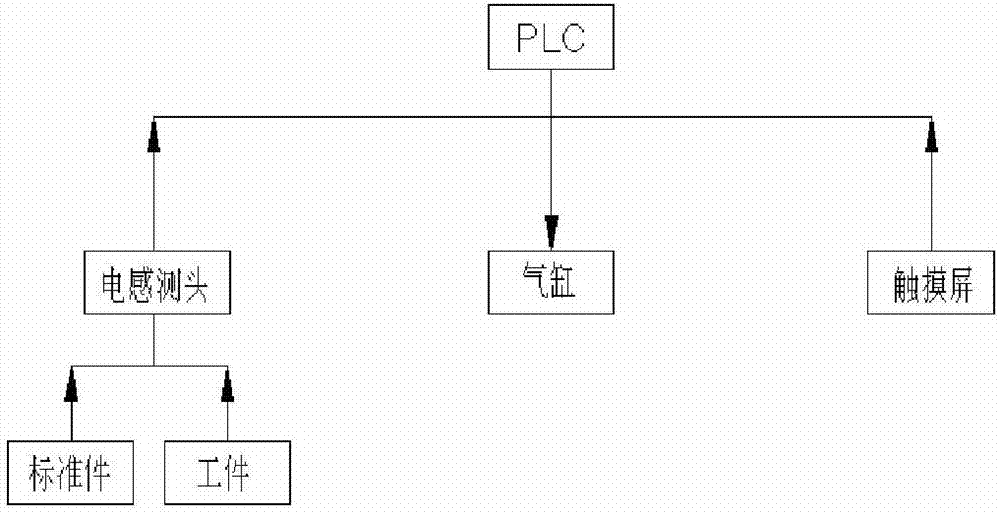

PendingCN107144212AImprove detection efficiencyGuaranteed accuracyElectric/magnetic contours/curvatures measurementsUsing electrical meansDisplay deviceUncrewed vehicle

The invention discloses flying drone engine's sleeving size and a geometrical error detection device. The programmable controller of the detection device is installed inside a base. The contact touch screen display and the support are fixedly arranged on the base. The sliding block cooperates with the guide rail arranged at the inner side of the support. The first measuring baseline block and the second measuring baseline block are installed at the lower end face of the sliding block. The inner measuring baseline column and the positioning ring are mounted on the base in a cooperative manner, and are arranged under the first measuring baseline block and the second measuring baseline block. The air cylinder is fixedly arranged at the upper end part of the support; the programmable controller controls the air cylinder piston to move and drives the sliding block to move upwards and downwards along the guide rail of the support. The inner measuring baseline column, and the first measuring baseline block as well as the second measuring baseline block are provided with a plurality of electric induction sensor probes. The electric induction sensor probes acquire and transmit the data to the programmable controller where the data are processed. The detection result is displayed through the contact touch screen display. The detection device can detect the diameters of the inner circle and the outer circle, the cylindricity and the coaxiality of the sleeving ring at one time while the sleeving ring is clamped. Therefore, the detection efficiency and quality are increased.

Owner:XIAN AISHENG TECH GRP +1

Method for automatically detecting center distance of battery tabs

ActiveCN103196383AStable, accurate and efficient size automatic detectionRealize automatic size detectionUsing optical meansLine segmentMovement control

The invention discloses a method for automatically detecting center distance of battery tabs. The detection system comprises an image processing unit, a motion control unit, a real-time monitoring unit and an upper computer, wherein the image processing unit performs software processing analysis on the acquired image to detect the size of the center distance of the tabs, namely the process comprises the steps: finding reference lines I1 and I2, a bottom reference line I8, and segments I4, I5, I6 and I7 through an image recognition method; fitting a central line I3 through the lines I1 and I2, respectively determining the vertexes R1 and R2 of positive and negative tabs through the intersection of the lines I4 and I5 and the intersection of the lines I6 and I7, and respectively determining base points R3 and R4 of the positive and negative tabs through the intersection of the lines I4 and I8 and the intersection of the lines I6 and I8; and respectively calculating the distances W1-W4 from the points R1-R4 to the central line I3, wherein the value is the center distance of the tabs. According to the method, the size of the center distance of the battery tabs can be rapidly, accurately and automatically detected.

Owner:无锡埃姆维工业控制设备有限公司

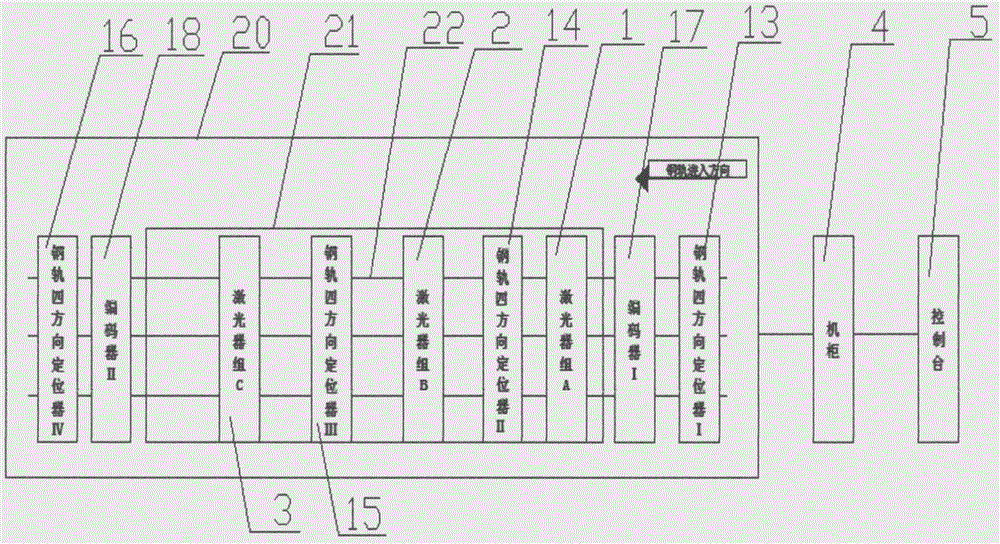

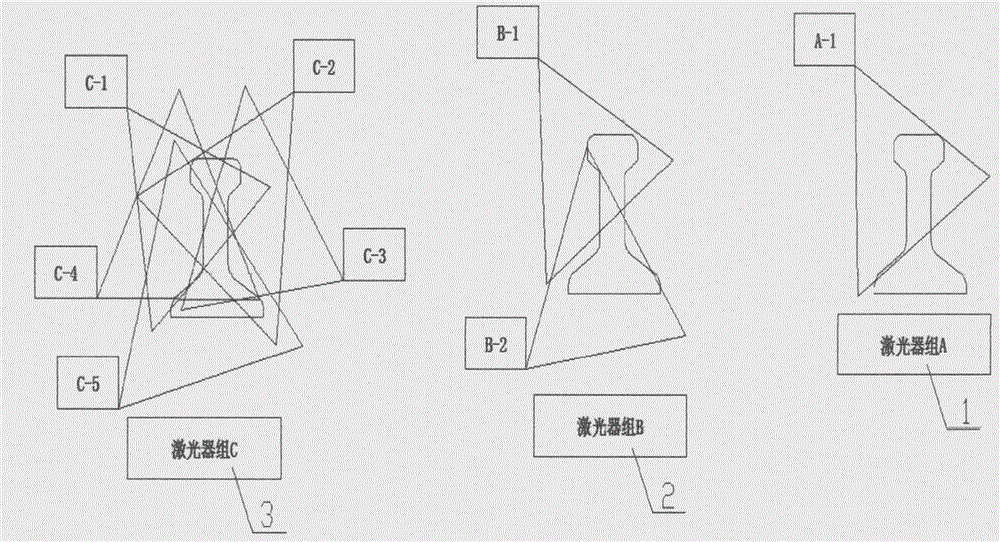

Steel rail appearance geometric dimension and surface defect detection device

InactiveCN106546176ARealize automatic track matchingRealize rail information entryOptically investigating flaws/contaminationUsing optical meansMeasurement deviceLaser sensor

The present invention discloses a steel rail appearance geometric dimension and surface defect detection device and belongs to the railway management technical field. The steel rail appearance geometric dimension and surface defect detection device comprises a measuring device, a cabinet and a console; the measuring device comprises a rigid support, a measuring cross beam, laser sets and steel rail four-directional locators; the laser set A, the laser set B and the laser set C are arranged on the rigid support along the entering direction of a steel rail; the steel rail four-directional locator I is arranged at the right side of the laser set A; the steel rail four-directional locator II is arranged between the laser set A and the laser set B; the steel rail four-directional locator III is arranged between the laser set B and the laser set C; the steel rail four-directional locator IV is arranged at the left side of the laser set C; the cabinet is connected with the measuring device; and the console is connected with the cabinet. According to the steel rail appearance geometric dimension and surface defect detection technology, the three sets of lasers, namely, eight two-dimensional laser sensors, are adopted to collect the contour data of the steel rail.

Owner:WUHAN HANNING TECH

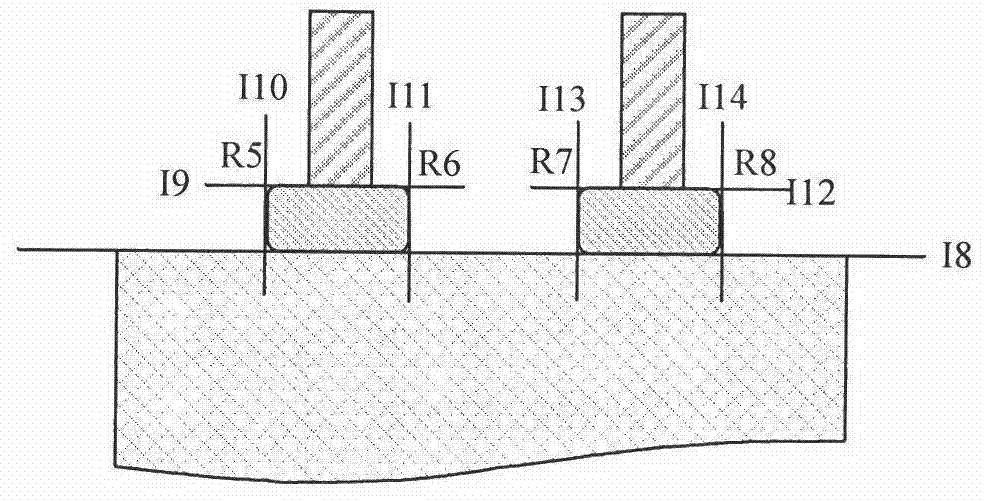

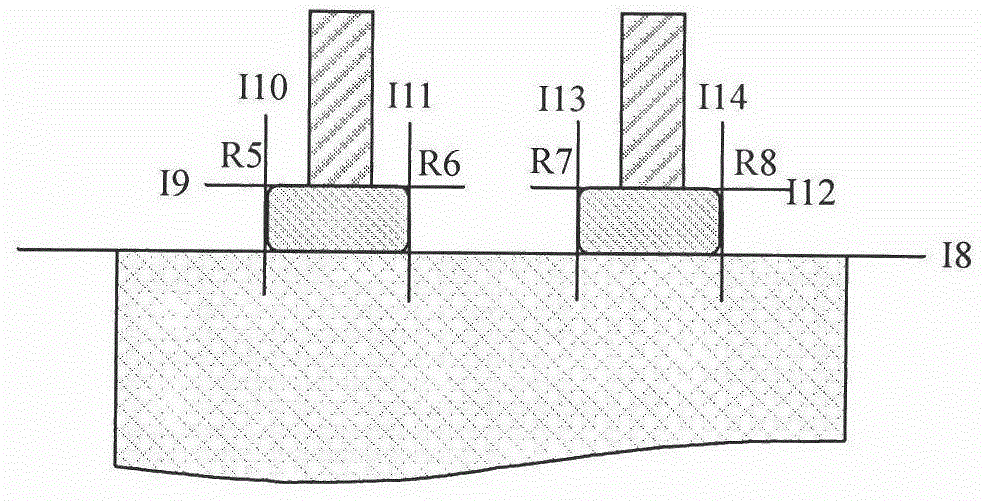

Automatic detection method of battery positive pole and negative pole tab-film heights

ActiveCN103196375AStable, accurate and efficient size automatic detectionRealization of size automatic detectionUsing optical meansImaging processingElectrical battery

The invention discloses an automatic detection method of battery positive pole and negative pole tab-film heights. A detection system comprises an image processing unit, a motion control unit, a real-time monitoring unit and a host computer. The image processing unit is used for carrying out software processing analysis on collected images and detecting tab-film sizes: a bottom datum line I8 and line segments I9, I10, I11, I12, I13 and I14 are found through an image recognition method. Negative pole tab-film peaks R5 and R6 are determined through intersection points between the line segment I9 and the line segments I10 and I11, positive pole tab-film peaks R7 and R8 are determined through intersection points of the line segment I12 and the line segments I13 and I14, the distances d1, d2, d3 and d4 from the R5, R6, R7 and R8 to the bottom datum line I8 are computed respectively, and the distance values are the pole tab-film heights. The method can achieve quick, accurate and automatic detection of the pole tab-film heights.

Owner:无锡埃姆维工业控制设备有限公司

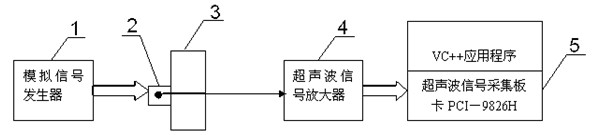

Ultrasonic imaging detection method for density distribution of high molecular polymer material

InactiveCN102692362AImprove test accuracyReal-time display of test resultsSpecific gravity measurementMeasurement pointDensity distribution

The invention relates to an ultrasonic imaging detection method for density distribution of a high molecular polymer material. A mechanical movement platform control module is used for controlling and driving an ultrasonic probe to move; an ultrasonic signal emitting and collecting module is used for collecting signals, processing the signals and sending the signals to a measurement control soft module in real time; and a measurement control software module supports an interface to display measurement state. The ultrasonic probe is used for scanning a plurality of measurement points and when the density of the measurement points changes, the ultrasound transmission speed of the measurement point also changes. By calculating the ultrasound transmission speed of each measurement point, the density value and the density distribution cloud picture of the high molecular polymer material are obtained. By adopting the method, the measurement result can be displayed in real time and the measurement accuracy is high.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

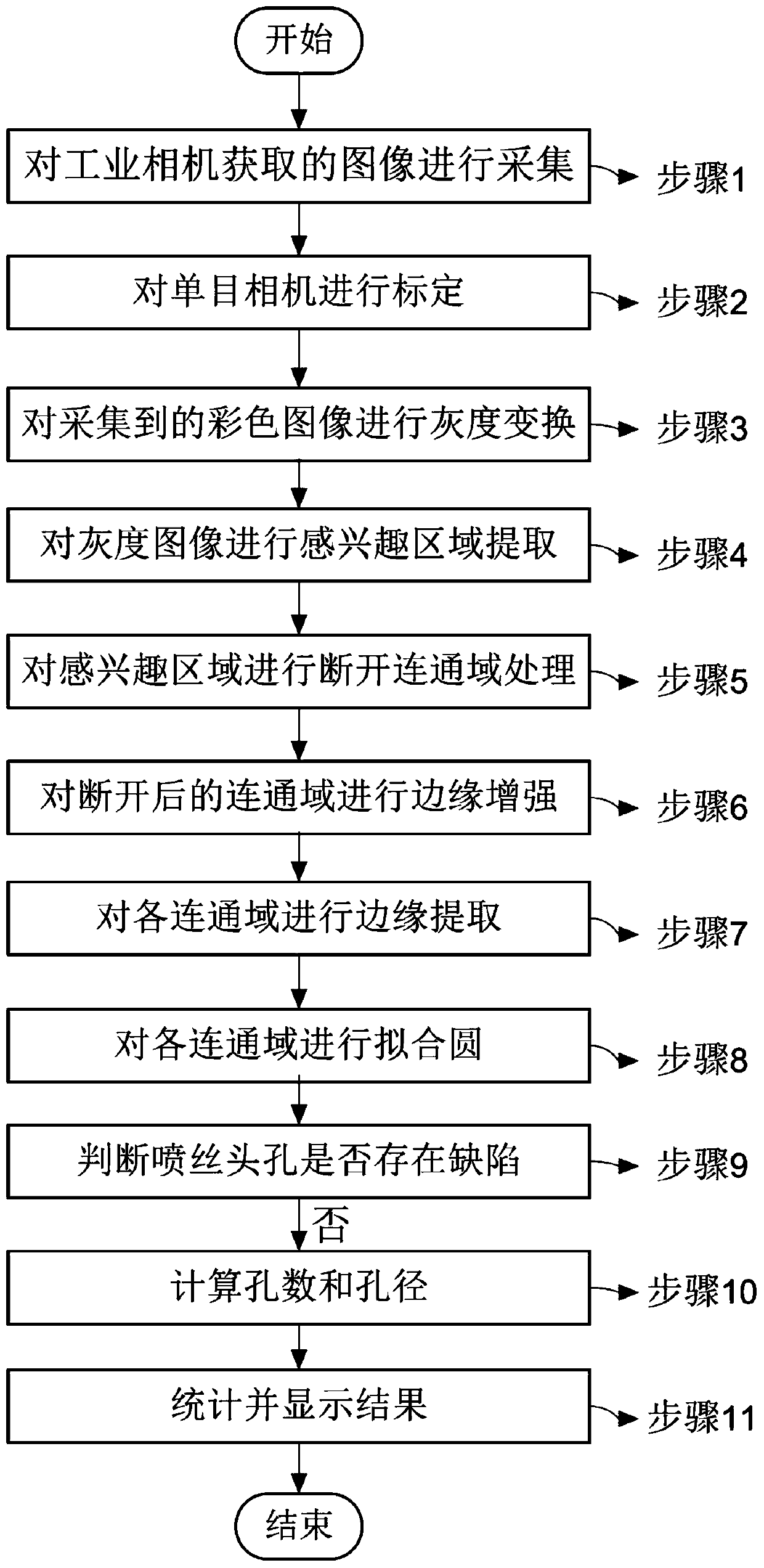

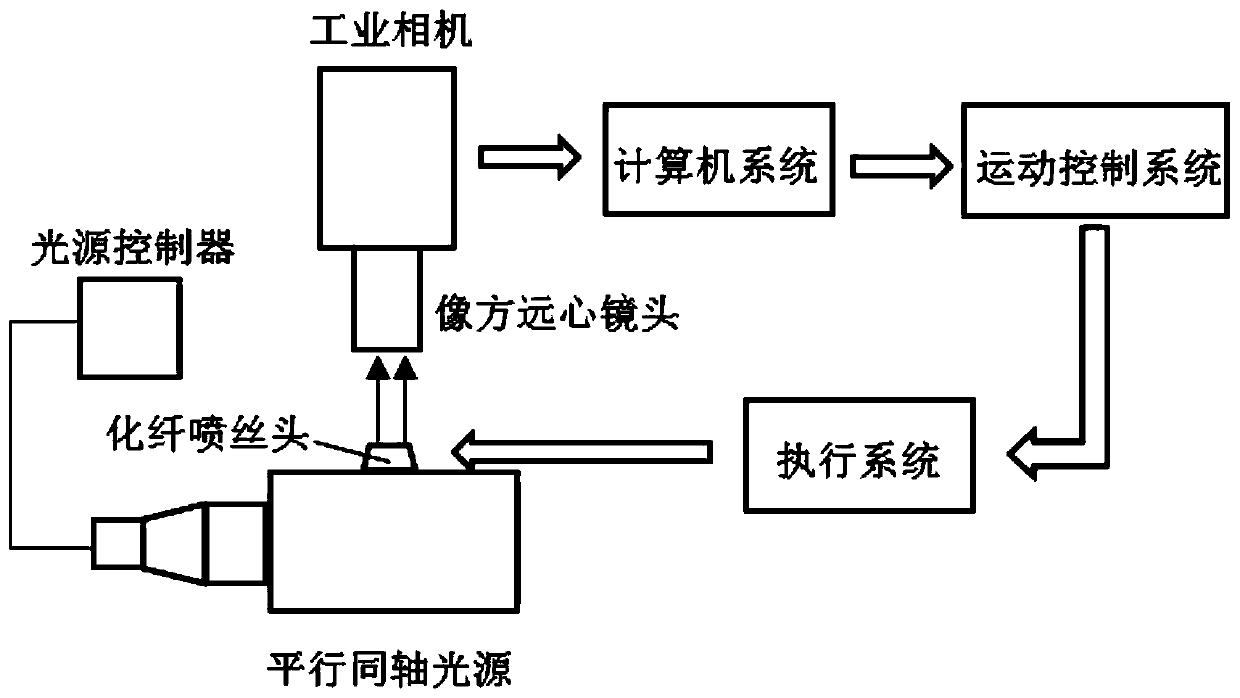

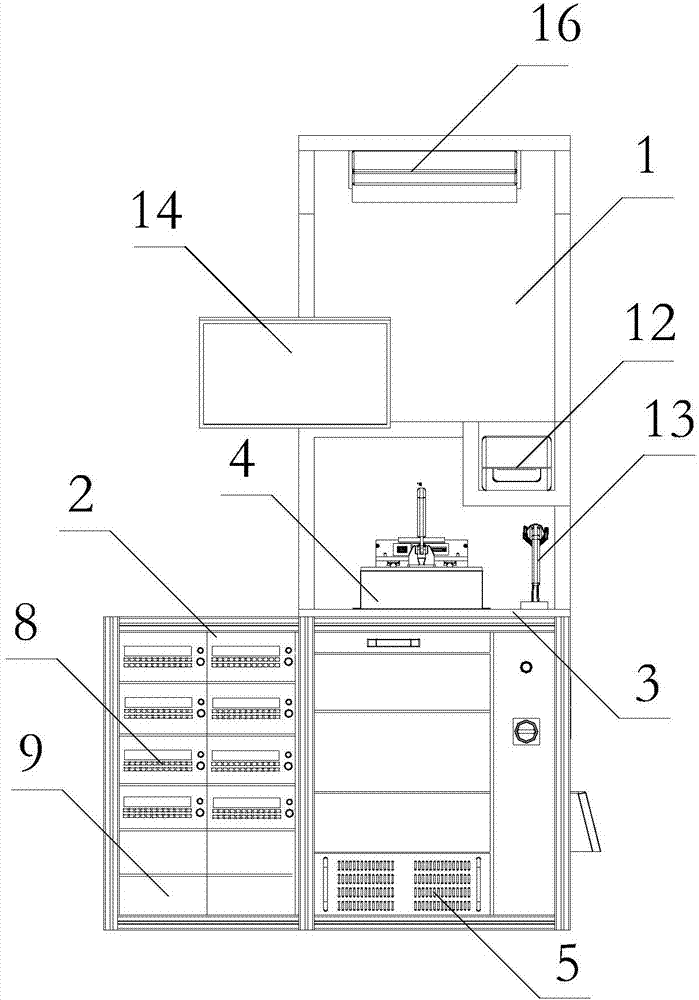

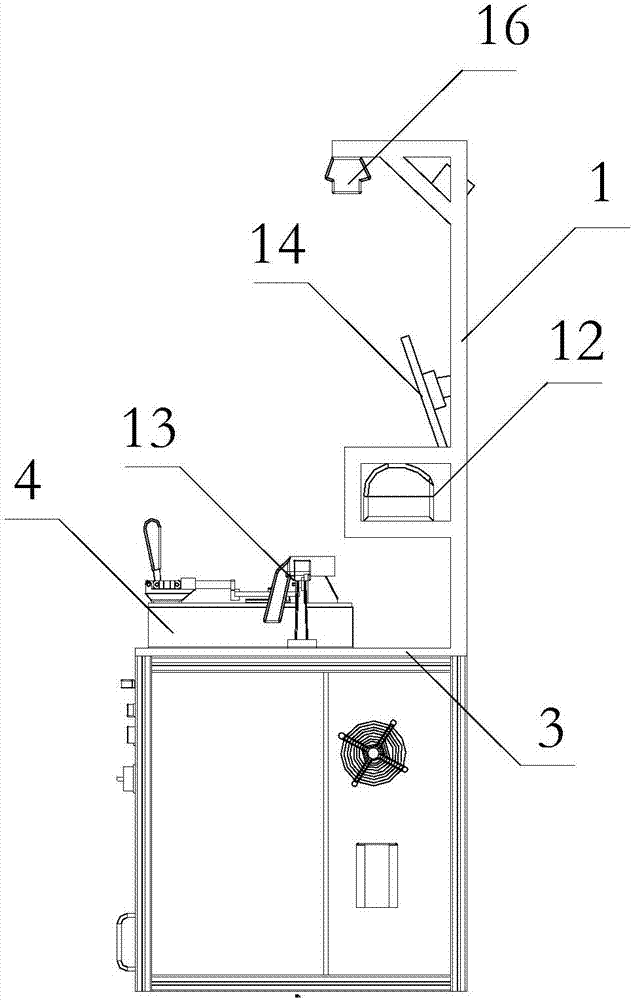

Machine vision-based defect detection method of chemical fiber spinning nozzle hole

InactiveCN110441318AReduce labor intensityReduce manufacturing costImage analysisCharacter and pattern recognitionMachine visionCommunications system

The invention discloses a machine vision-based defect detection method of a chemical fiber spinning nozzle hole. The machine vision-based defect detection method involves a defect detection algorithm,a light source, an industrial camera, a computer system, a control and communication system and an execution system. By a series of pre-processing and defect detection algorithms on an image acquiredby the industrial camera, detection on defects such as plug and burrs of the chemical fiber spinning nozzle hole and on aperture and hole numbers is achieved, the detection efficiency and accuracy can be improved, the labor intensity of a worker is reduced, meanwhile, the production cost of an enterprise is reduced, and a detection result can be displayed in real time.

Owner:ZHENGZHOU UNIV

Automatic detection equipment of automobile body control module

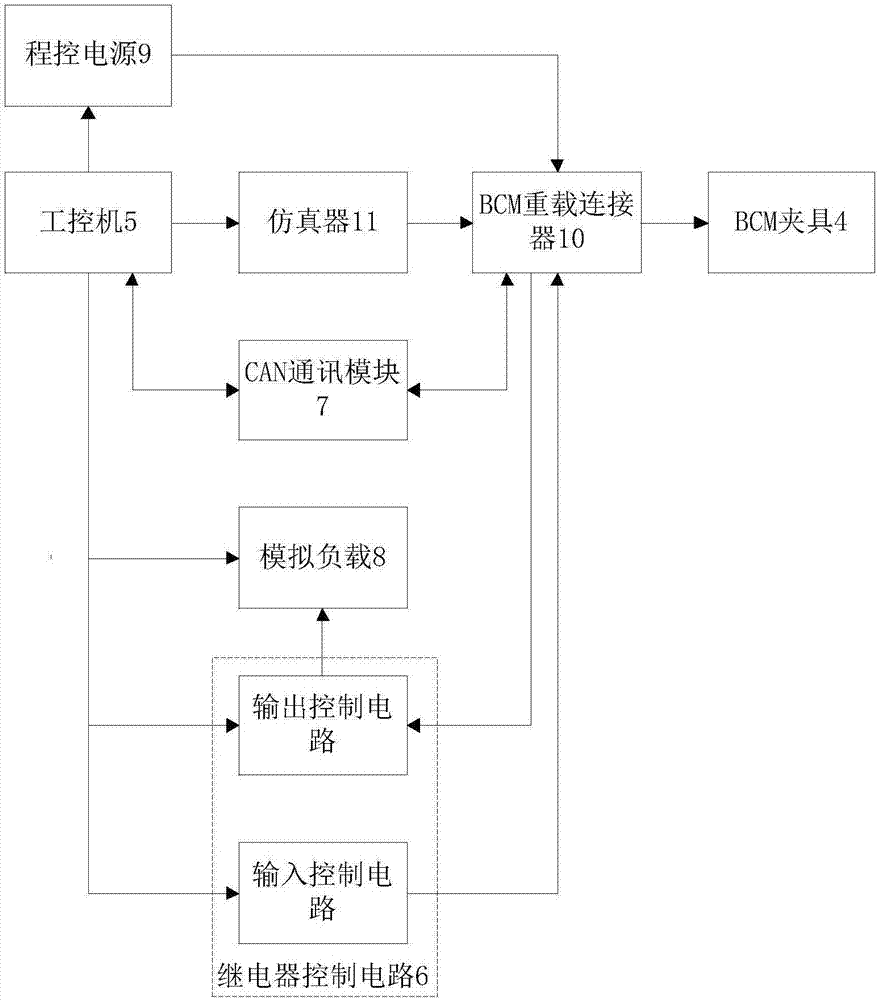

PendingCN106933217AImprove detection efficiencyHigh degree of automationElectric testing/monitoringControl engineeringControl circuit

The invention relates to automatic detection equipment of an automobile body control module. The automatic detection equipment comprises a detection cabinet, a load cabinet and a detection circuit. The detection cabinet and the load cabinet are adjacently arranged. A detection table is arranged on the detection cabinet. The detection circuit comprises a body control module BCM clamp, an industrial control computer, a relay control circuit, a CAN communication module, a simulation load, a program control power supply and a BCM heavy load connector. The BCM clamp is arranged on the detection table and fixes a BCM to be detected. The industrial control computer and the relay control circuit are arranged in the detection cabinet and arranged below the detection table. The simulation load and the program control power supply are arranged in the load cabinet. All the logical functions of the automobile body control module BCM can be efficiently detected through the simulation load, and different load output channels of the BCM can be selectively detected through the relay control circuit so that the detection efficiency is high, the degree of automation is high, the equipment is stable and reliable and the detection result is accurate.

Owner:WUHAN SOUTH SAGITTARIUS INTEGRATION CO LTD

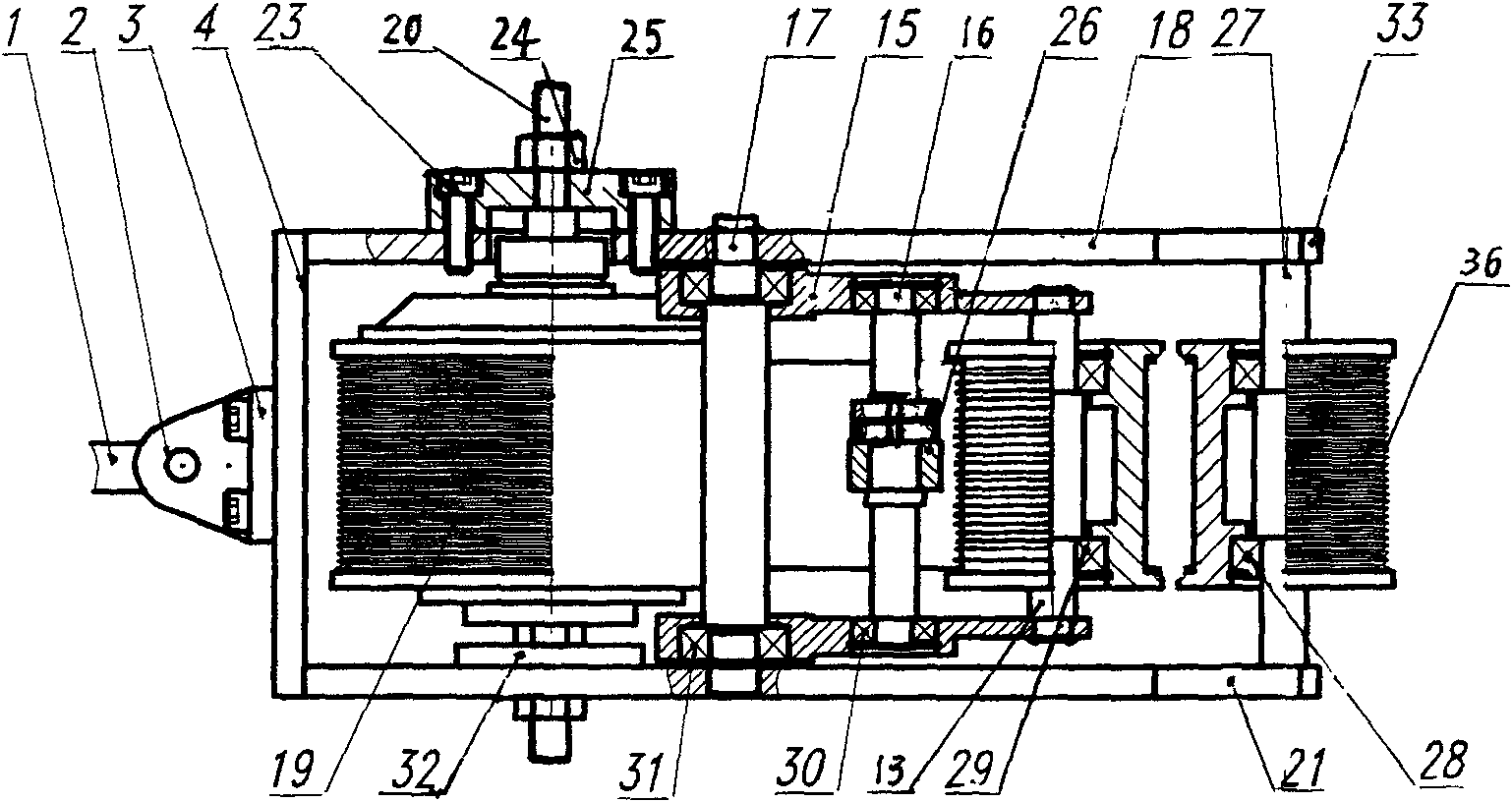

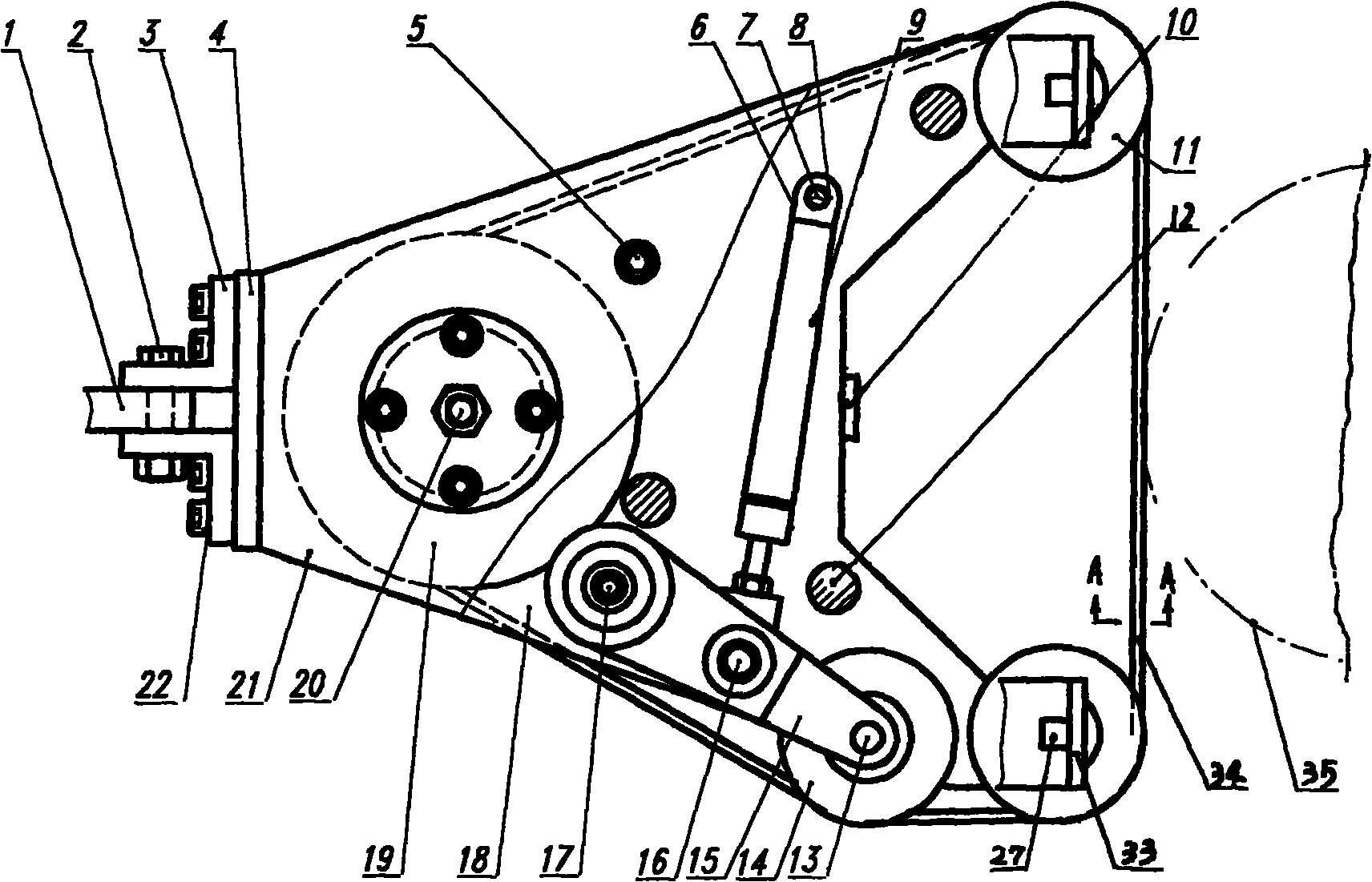

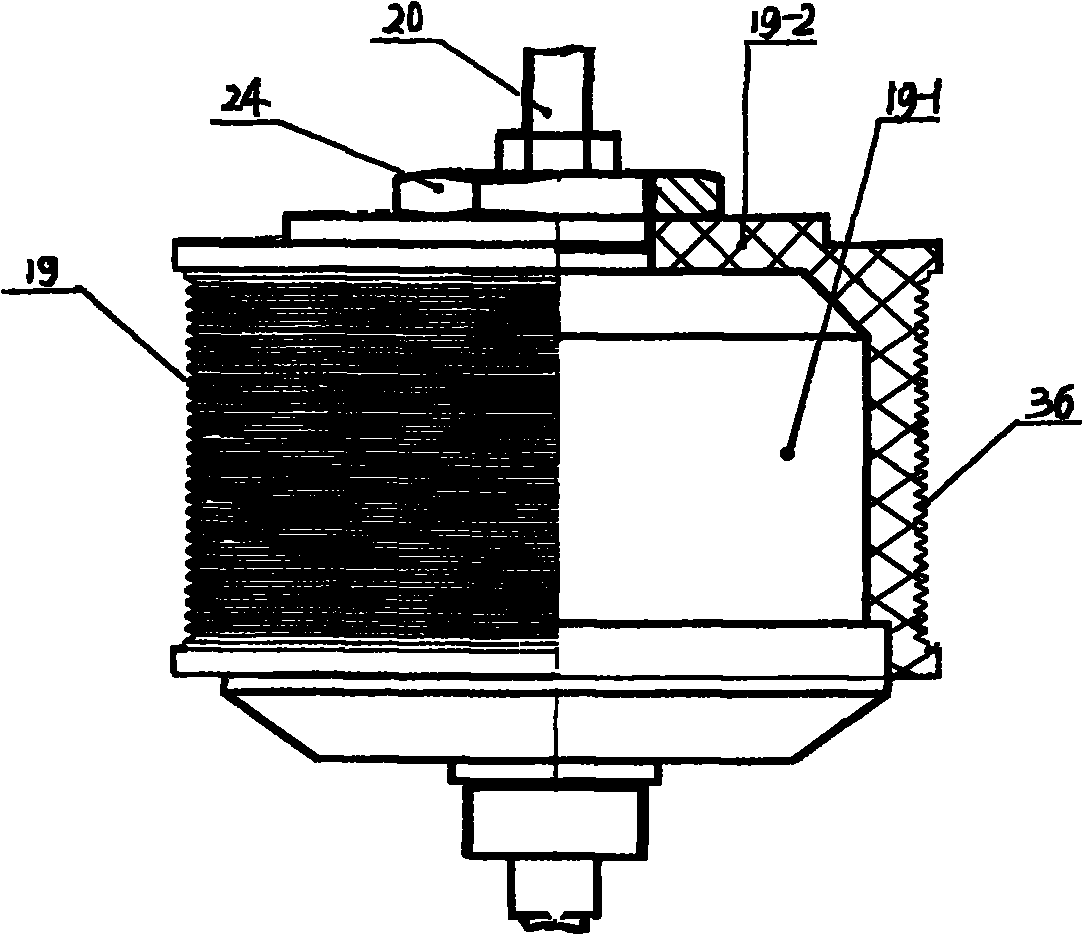

Tightness self-regulating rotating mechanism of bearing performance precision detection instrument

InactiveCN101995335AGuaranteed detection accuracyEliminate the influence of human factorsMachine bearings testingAir springEngineering

The invention relates to a tightness self-regulating rotating mechanism of a bearing performance precision detection instrument, which comprises a direct current brushless motor 19-1 and a tensioning air spring. The tightness self-regulating rotating mechanism is characterized in that the direct current brushless motor 19-1 and a driving wheel 19-2 are fixed together, the driving wheel 19-2 is movably arranged on a driving wheel shaft 20, the driving wheel shaft 20 is fixedly arranged on a left clamp plate 18 and a right clamp plate 21, the middle sections of the left clamp plate 18 and the right clamp plate 21 are respectively and fixedly provided with a centering shaft 17, two swinging arms 15 are movably arranged on each centering shaft 17 by a fourth bearing 31, a support shaft 16 is movably arranged in the middle of the swinging arms 15 by a third bearing 30, the middle of the support shaft 16 is movably provided with a support rod 26, the support rod 26 is connected with one end of the tensioning air spring 9, the other end of the tensioning air spring 9 is fixed on a fixed air cylinder seat 6, and the fixed air cylinder seat 6 is movably arranged on a fixed air cylinder shaft through a fixed air cylinder sleeve 8. The tightness self-regulating rotating mechanism realizes high-precision detection on the axial play, the assembly height and the end surface jumping of bearings, realizes the rotating kinetic energy required by the detection and can simulate real operation to achieve the full automation of the detection process.

Owner:DALIAN HUAKONG INDAL EQUIP

Tension testing device of traction belt

InactiveCN102928290ASimple structureEasy to testMaterial strength using tensile/compressive forcesEmbedded systemTraction belt

The invention provides a tension testing device of a traction belt, which relates to the technical field of tension testing equipment. The tension testing device comprises a testing mechanism, a power distribution cabinet mechanism, a tension mechanism and a control mechanism, wherein the tension mechanism is connected with the testing mechanism and used for pulling the testing mechanism to move; the power distribution cabinet mechanism is connected with the tension mechanism and the testing mechanism so as to provide a power supply to the tension mechanism; and the control mechanism is connected with the power distribution cabinet mechanism, is used for controlling the operation of the whole device and can be used for storing and displaying a testing result. The tension testing device of the traction belt, provided by the invention, has the advantages of simple structure, convenience for testing as well as safety and reliability in use, can be suitable for testing tensions of the traction belts or safety belts with various sizes, and can be used for displaying the testing results in real time.

Owner:安徽恒索带业有限公司

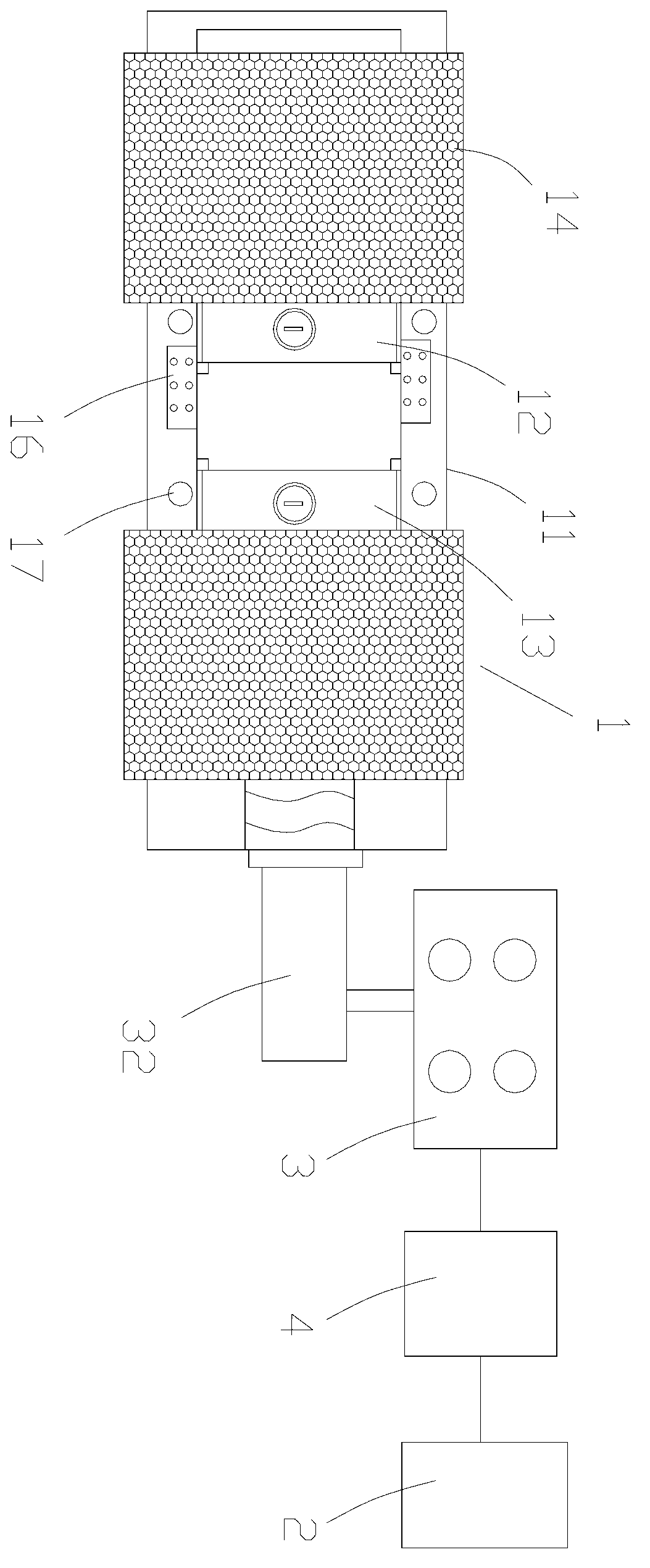

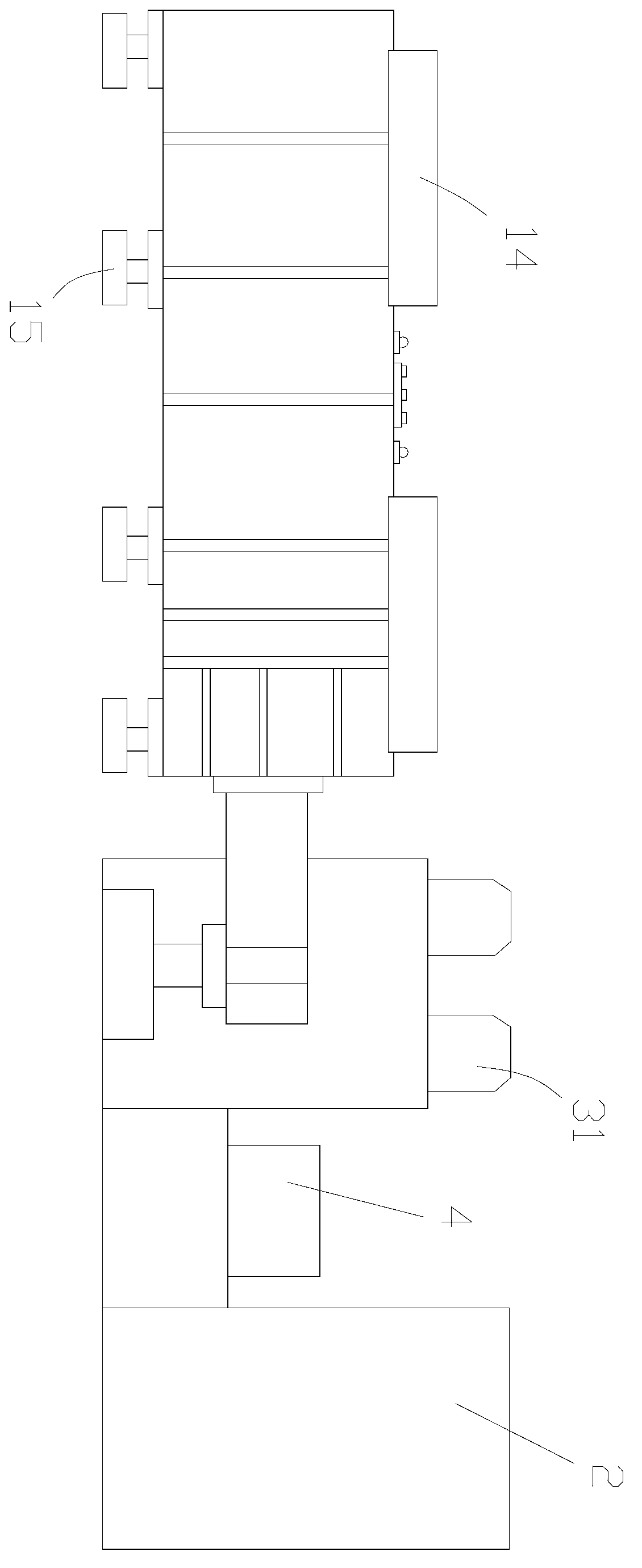

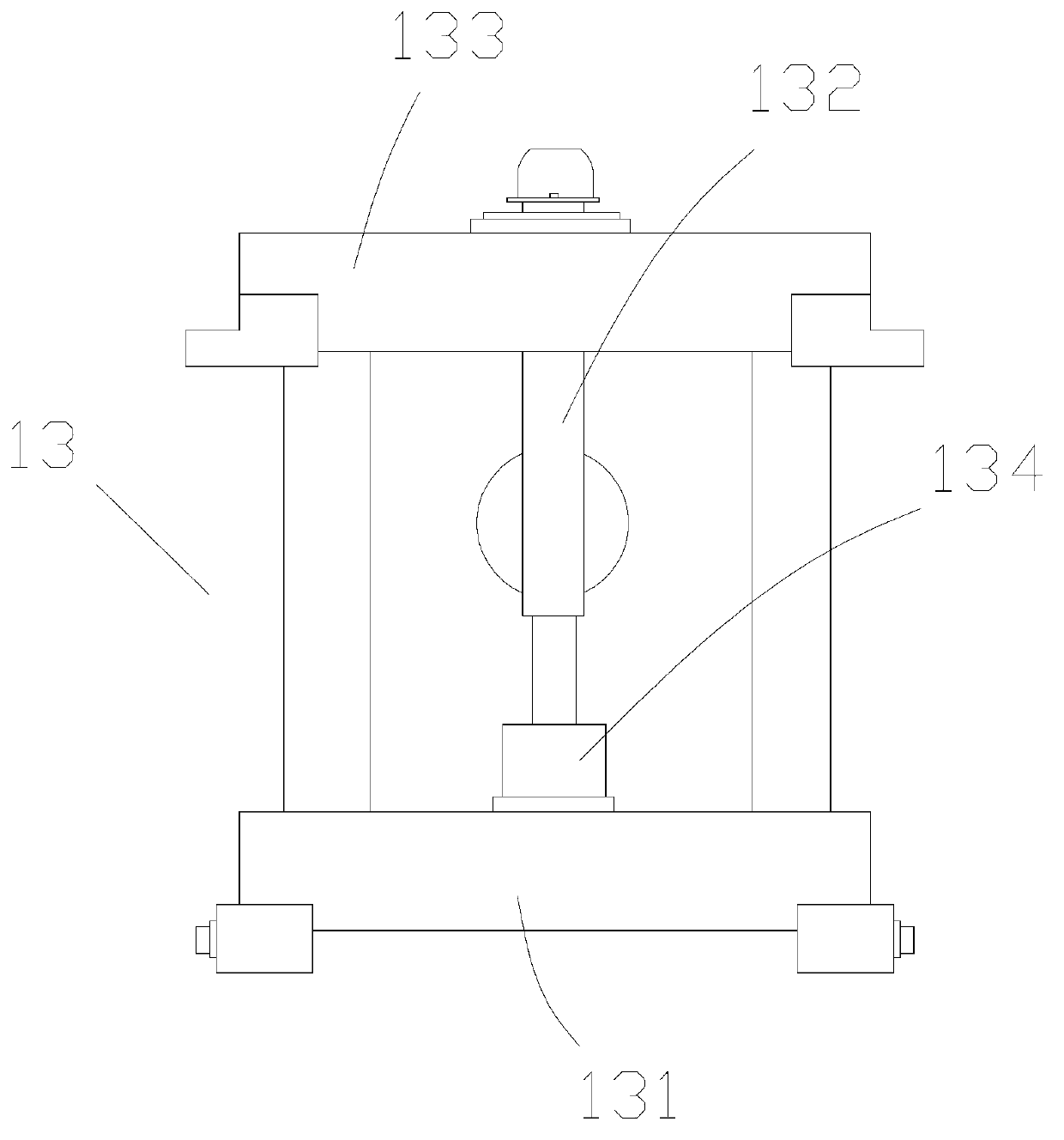

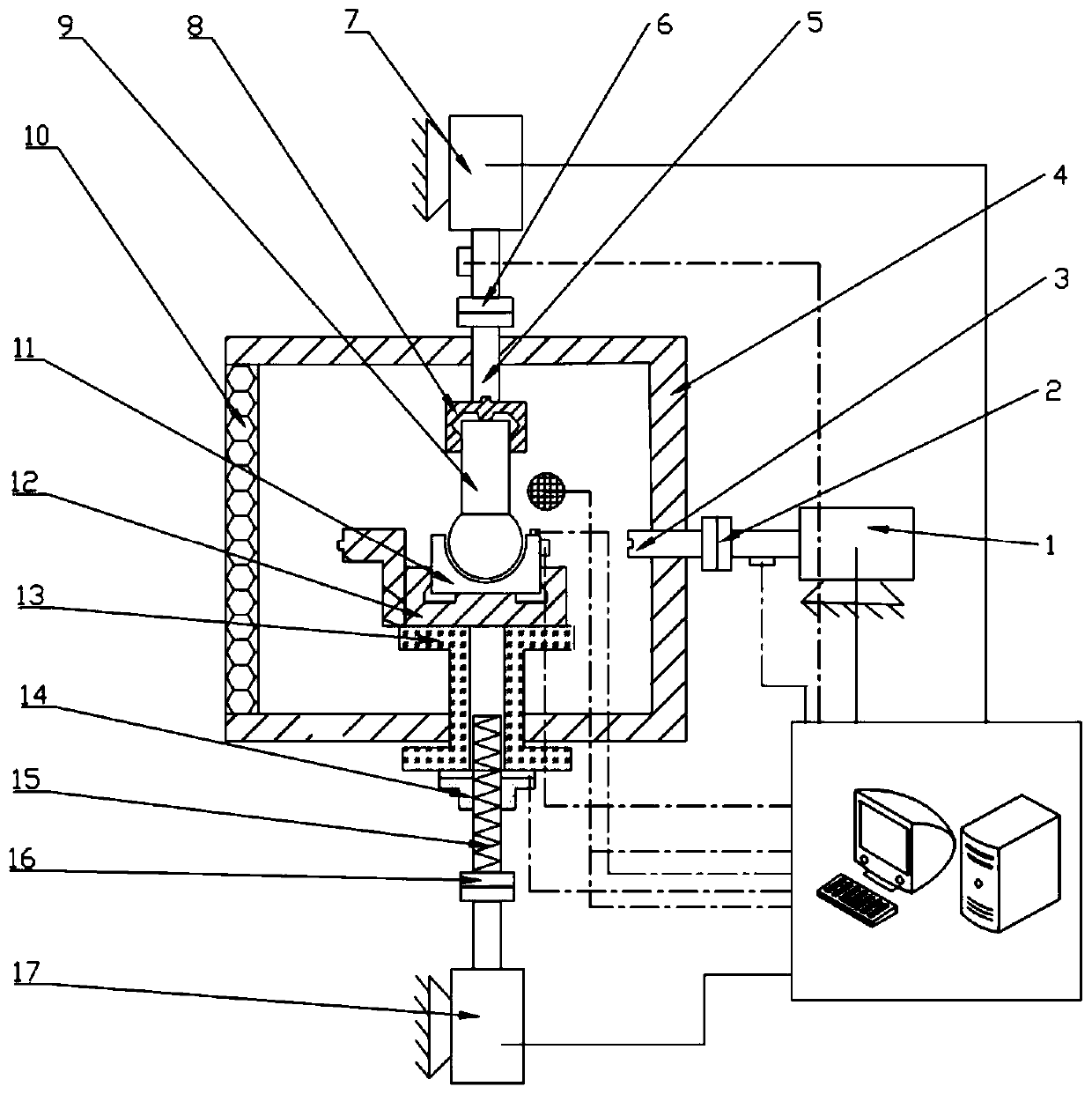

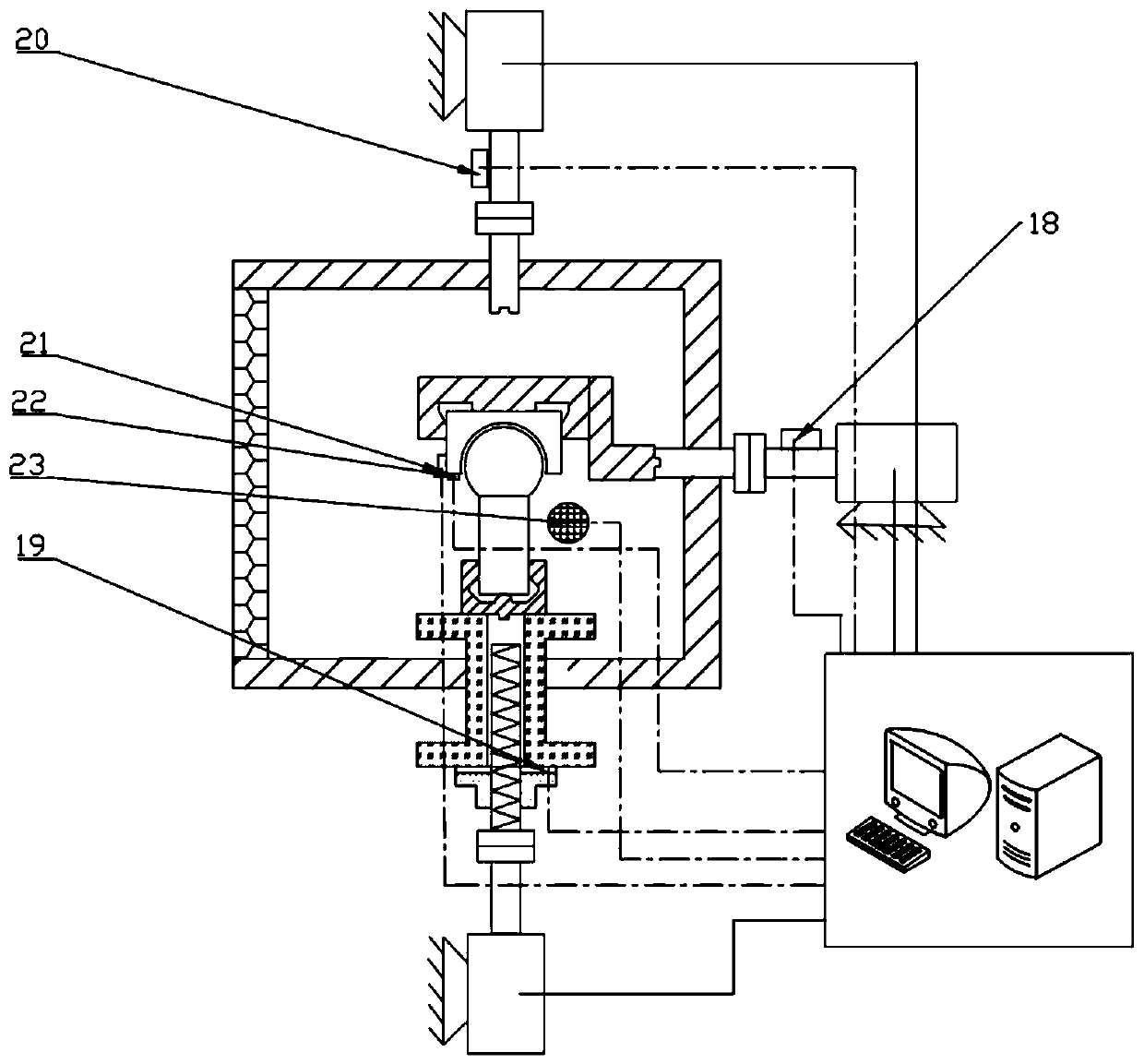

Test device and method for robot ball-and-socket joint friction pair

ActiveCN110095286ASimple structureReal-time display of test resultsMachine part testingWear testingAnalog robot

The invention discloses a test device and a test method for a robot ball-and-socket joint friction pair, aiming at the problem that the existing wear testing machine is difficult to simulate the actual wear condition of the robot ball-and-socket joint friction pair. The test device comprises a first rotating shaft, a second rotating shaft, a loading shaft, a joint socket fixture and a joint head fixture, wherein the second rotating shaft and the loading shaft are coaxial, and the first rotating shaft is perpendicular to the loading shaft. Through adopting fixing modes of different combinationsof the joint socket fixture and the joint head fixture on the first rotating shaft, the second rotating shaft and the loading shaft, the ball-and-socket joint rotation and swing tests are completed in the same set of devices, the dynamic measurement of wear amount is realized without damaging a paring relationship by means of a sensitive galvanometer, and the test result is high in precision.

Owner:HANGZHOU DIANZI UNIV

An automatic detection method for the height of battery positive and negative ear gels

ActiveCN103196375BStable, accurate and efficient size automatic detectionRealization of size automatic detectionUsing optical meansImaging processingMotion control

The invention discloses an automatic detection method of battery positive pole and negative pole tab-film heights. A detection system comprises an image processing unit, a motion control unit, a real-time monitoring unit and a host computer. The image processing unit is used for carrying out software processing analysis on collected images and detecting tab-film sizes: a bottom datum line I8 and line segments I9, I10, I11, I12, I13 and I14 are found through an image recognition method. Negative pole tab-film peaks R5 and R6 are determined through intersection points between the line segment I9 and the line segments I10 and I11, positive pole tab-film peaks R7 and R8 are determined through intersection points of the line segment I12 and the line segments I13 and I14, the distances d1, d2, d3 and d4 from the R5, R6, R7 and R8 to the bottom datum line I8 are computed respectively, and the distance values are the pole tab-film heights. The method can achieve quick, accurate and automatic detection of the pole tab-film heights.

Owner:无锡埃姆维工业控制设备有限公司

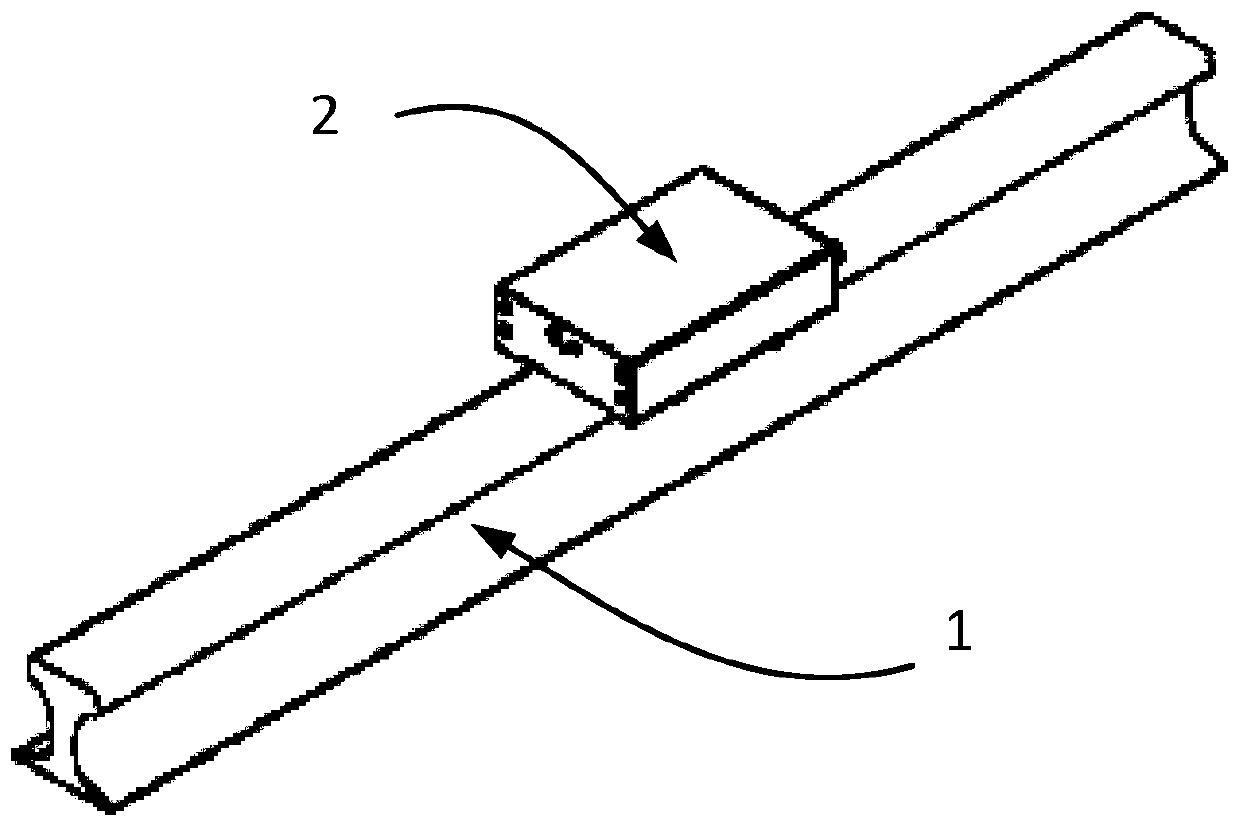

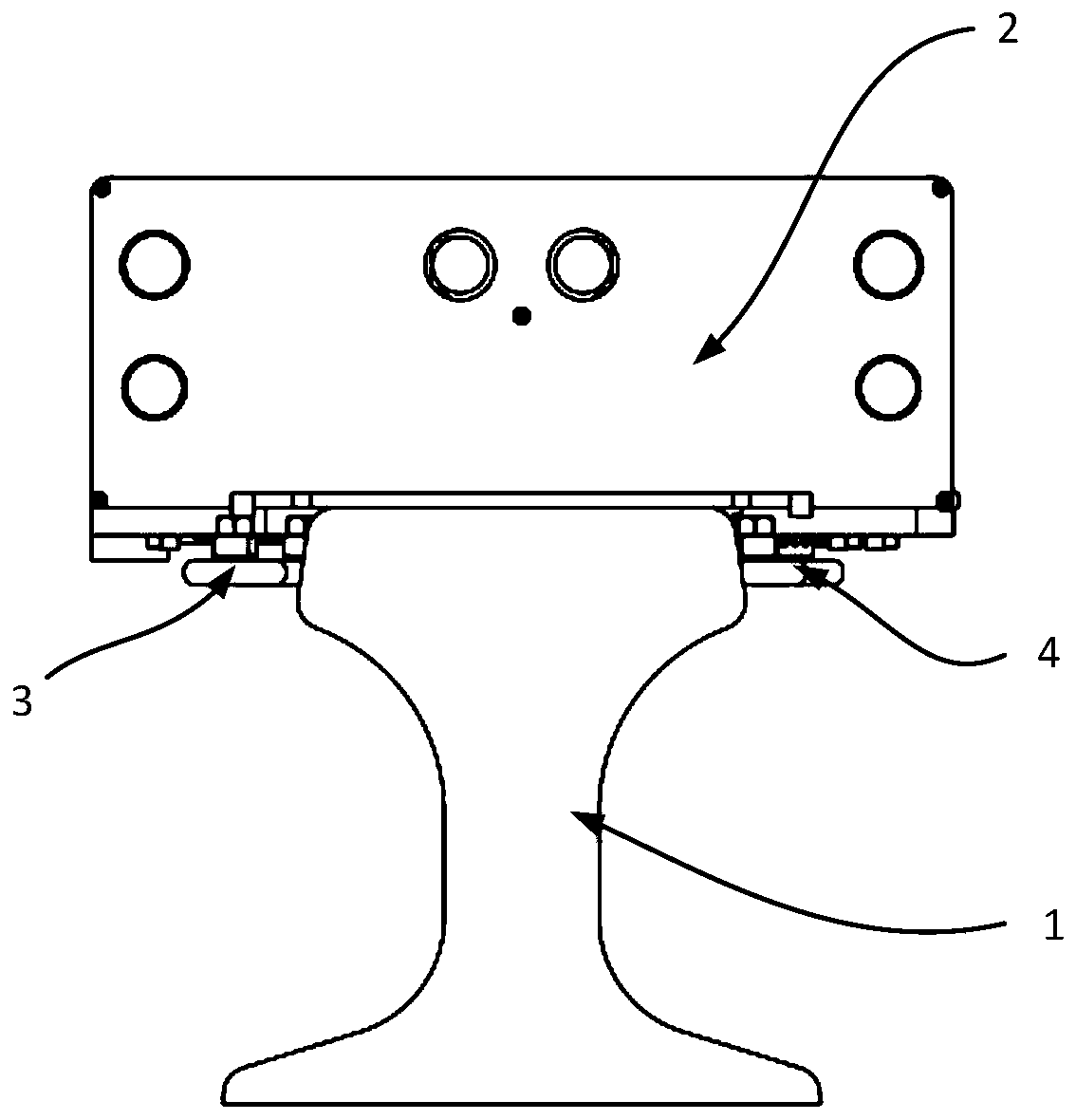

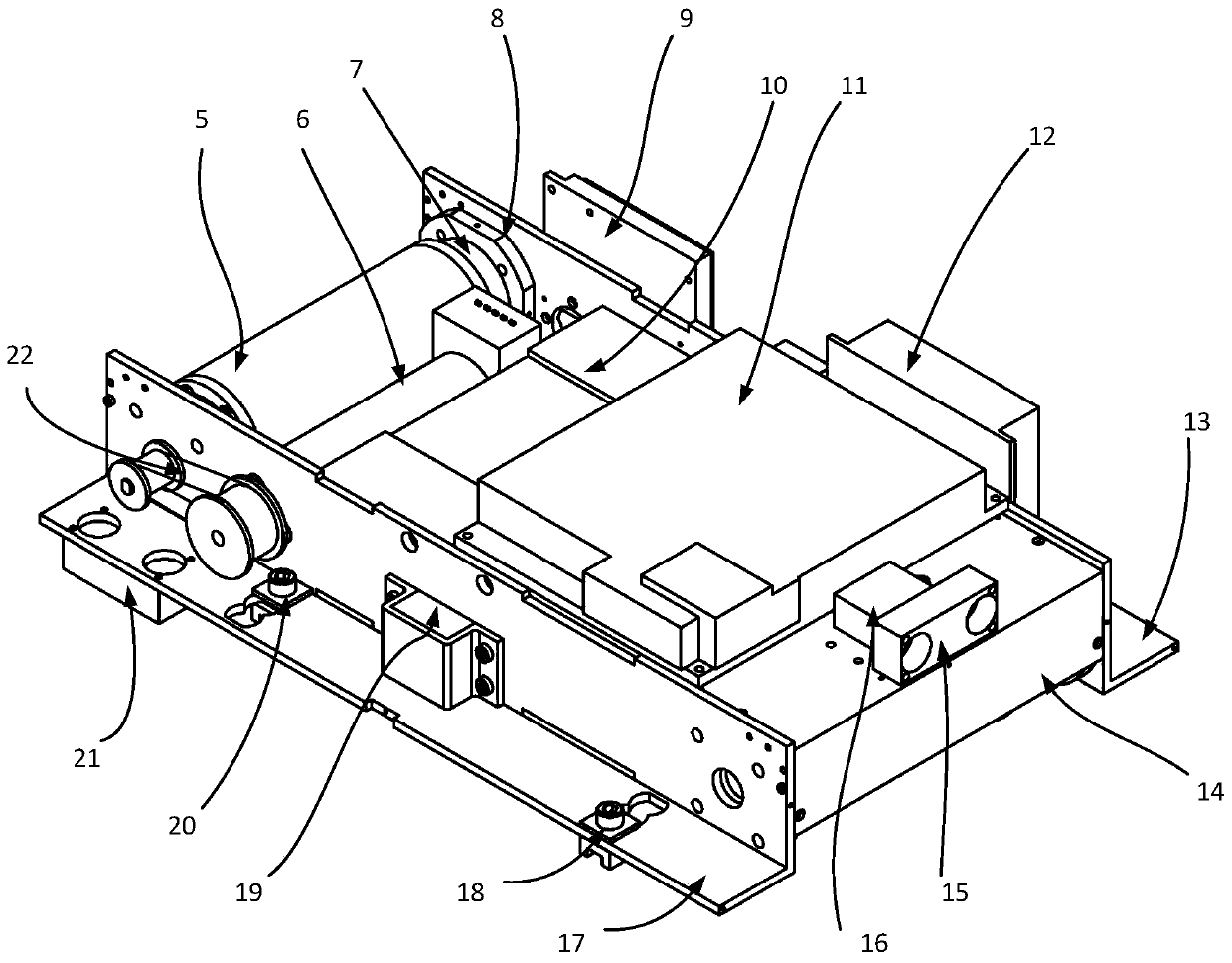

Monorail contact type track detection vehicle

PendingCN110254451AEasy maintenanceReal-time display of test resultsRailway inspection trolleysAcoustic wave reradiationUltrasonic sensorContact type

The invention discloses a monorail contact type track detection vehicle. The vehicle comprises a vehicle body, a plurality of ultrasonic sensors, a driving component, a plurality of pairs of guide wheels, a side sensor, a vertical sensor, a controller and a signal processing unit; the ultrasonic sensors are arranged at the front end, the rear end and the side portion of the vehicle body correspondingly; the driving component is arranged on the vehicle body and is used for driving the vehicle body to move on a track; the plurality of pairs of guide wheels are arranged at the bottom of the vehicle body, and each pair of guide wheels is located on the two sides of the track correspondingly and is tightly attached to the side surfaces of the track; and the side sensor, the vertical sensor, the controller and the signal processing unit are arranged in the vehicle body and are used for receiving signals from the plurality of ultrasonic sensors, the vertical sensor and the side sensor and / or sending an instruction to the controller.

Owner:SHANGHAI MARITIME UNIVERSITY

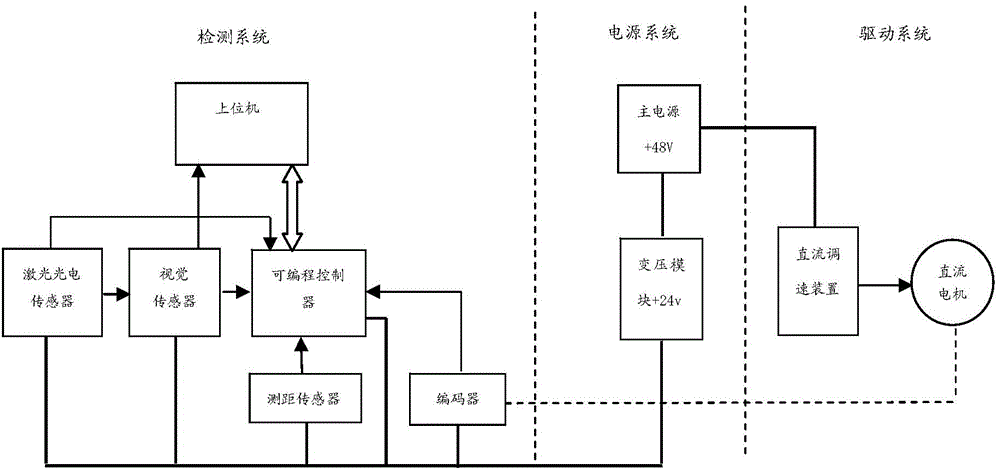

Lower-contact type metro contact rail detecting system

InactiveCN104442916ASimple structureThe detection method is simpleUsing optical meansRailway auxillary equipmentEngineeringContact type

The invention relates to the technical field of rail detection, in particular to a lower-contact type metro contact rail detecting system. The lower-contact type metro contact rail detecting system comprises a detecting system body and a power system used for supplying power to the detecting system body. The detecting system body comprises an encoder, a laser photoelectric sensor, a vision sensor, an upper computer, a distance measuring sensor and a programmable controller. The encoder is connected with the programmable controller, the laser photoelectric sensor is connected with the vision sensor and the programmable controller through signals, and the vision sensor is connected with the upper computer and the programmable controller. The lower-contact type metro contact rail detecting system is simple in structure, detection parameters are visual and effective, a detection method is simple, the response speed is high, and the earlier-stage characters of contact rail faults can be reflected; manual detection is replaced by automatic detection, the number of workers is small, the labor intensity is reduced, and work can be completed only with one person.

Owner:TIANJIN SINO GERMAN VOCATIONAL TECHN COLLEGE +1

High-flux tea tree organophosphorus pesticide residue detection device based on radioactive flow sample introduction

PendingCN113514650ARealize residue detectionRealize automatic levelingMaterial analysisPeristaltic pumpAgricultural science

The invention discloses a high-flux tea tree organophosphorus pesticide residue detection device based on radial flow sample introduction, and belongs to the field of biological detection.The high-flux tea tree organophosphorus pesticide residue detection device comprises a base, a lamp strip and a camera are installed on the top wall of the base, and a support stand column is installed at the edge of the top wall of the base; and a paper chip bearing table, a funnel frame, a water pipe fixing frame, a control box, an annular support and a Z-shaped support are sequentially fixed to the support stand column from bottom to top, a microprocessor and a circuit board are arranged in the control box, wire inlets are reserved in the centers of the upper surface and the lower surface of the control box, and the control box is connected with a peristaltic pump, an adjusting mechanism, a radiation flow liquid separation device and a PTC heating plate through a plurality of wires. According to the invention, high-flux tea pesticide residue detection can be realized, pesticide residues on the surface of tea can be more thoroughly eluted, the whole reaction process is automatically carried out, manual reagent addition is not needed, manual operation is reduced, errors are reduced, the detection efficiency is high, whether the organophosphorus pesticide in a sample exceeds the standard or not is intelligently judged, the detection result can be displayed in real time, and the use is convenient.

Owner:JIANGSU UNIV

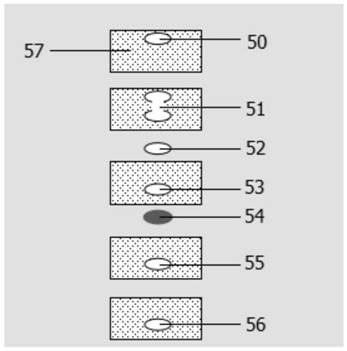

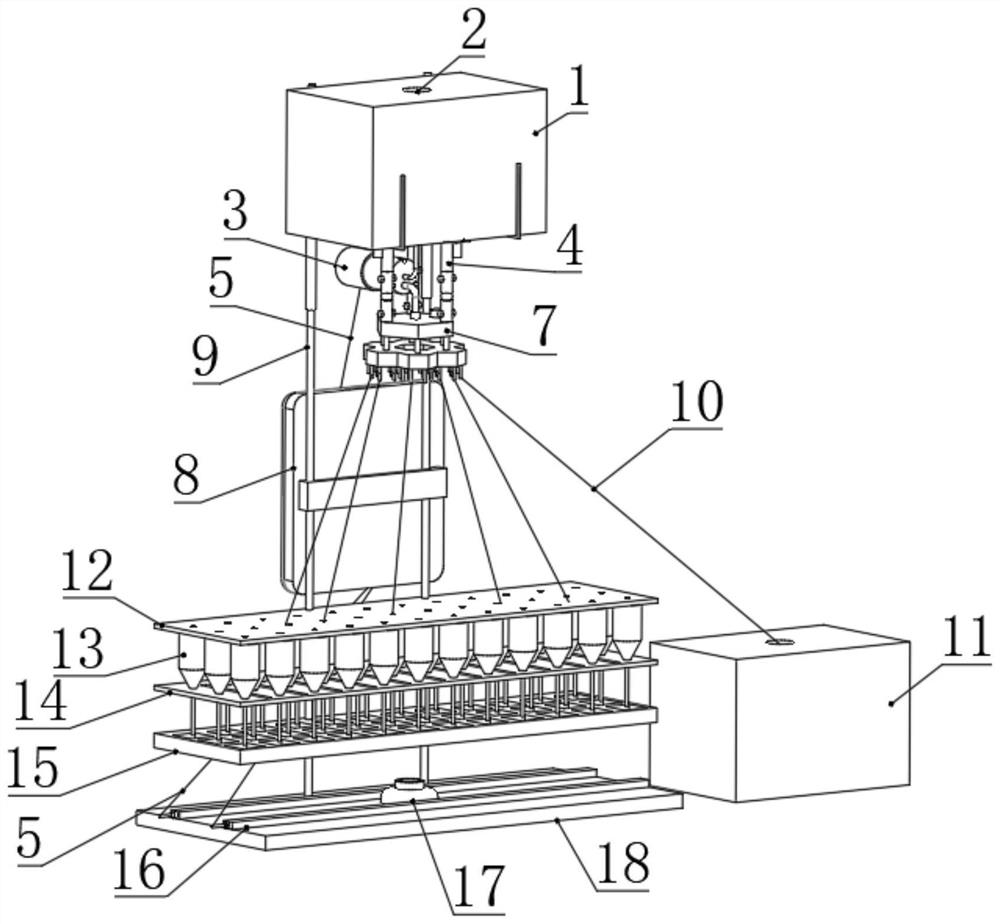

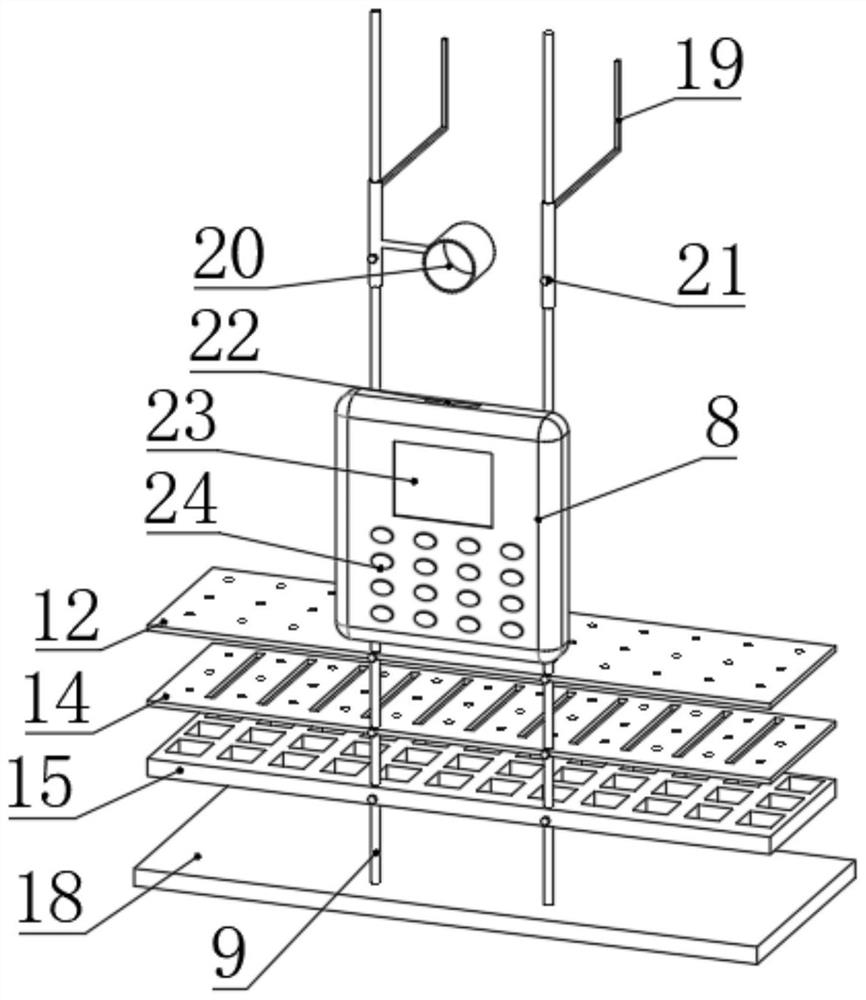

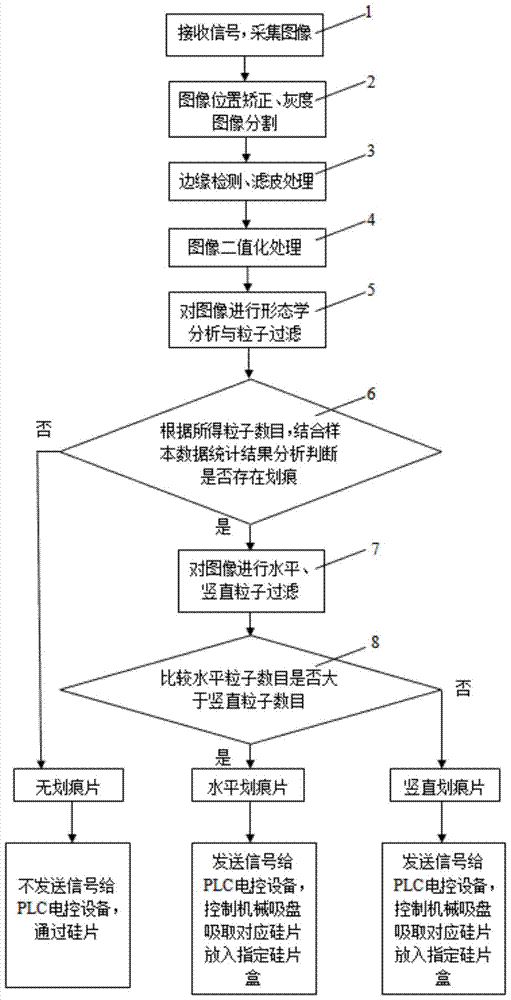

Scratch detection method on raw silicon wafer surface based on machine vision

ActiveCN105388162BReal-time display of test resultsOptically investigating flaws/contaminationLinear filterData acquisition

The invention discloses a method for detecting scratches on the surface of raw silicon wafers based on machine vision, which belongs to the technical field of machine vision defect detection, and adopts image position correction technology, grayscale image segmentation technology, linear filtering technology, edge detection technology, data statistics and analysis technology, image processing technology, and morphological analysis to process and analyze the collected images; filter the image, initially extract the surface scratch information, further highlight the scratch position and size after binarization processing, and finally Primary scratches were screened out by morphological analysis and particle filtration methods. The invention can realize online stable and accurate judgment of the existence and directionality of scratches on the surface of raw silicon wafers, and display the detection results in real time; and can send signals to the PLC controller controlling the conveyor belt through the data acquisition module, so that it can correspond to different Categories Quickly control the conveyor belt to take different actions.

Owner:ZHENJIANG SYD TECH CO LTD

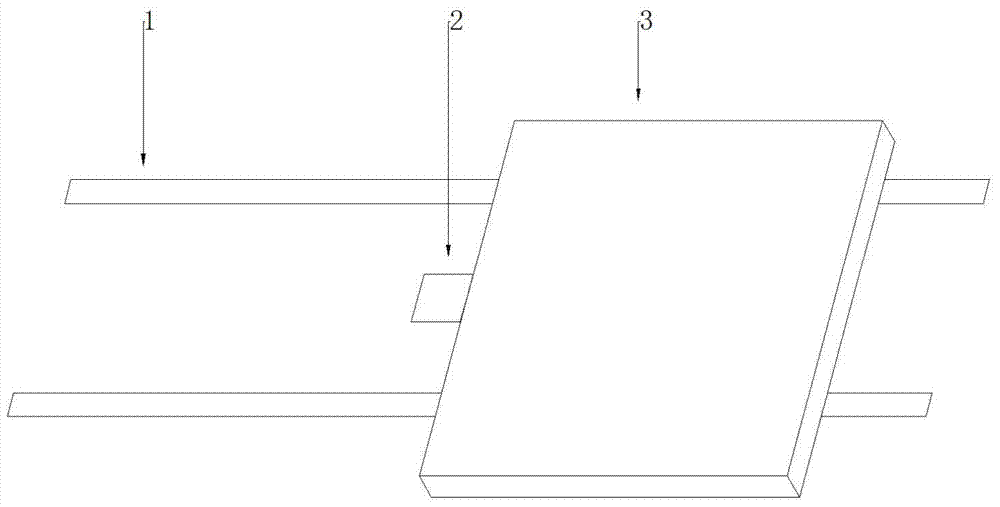

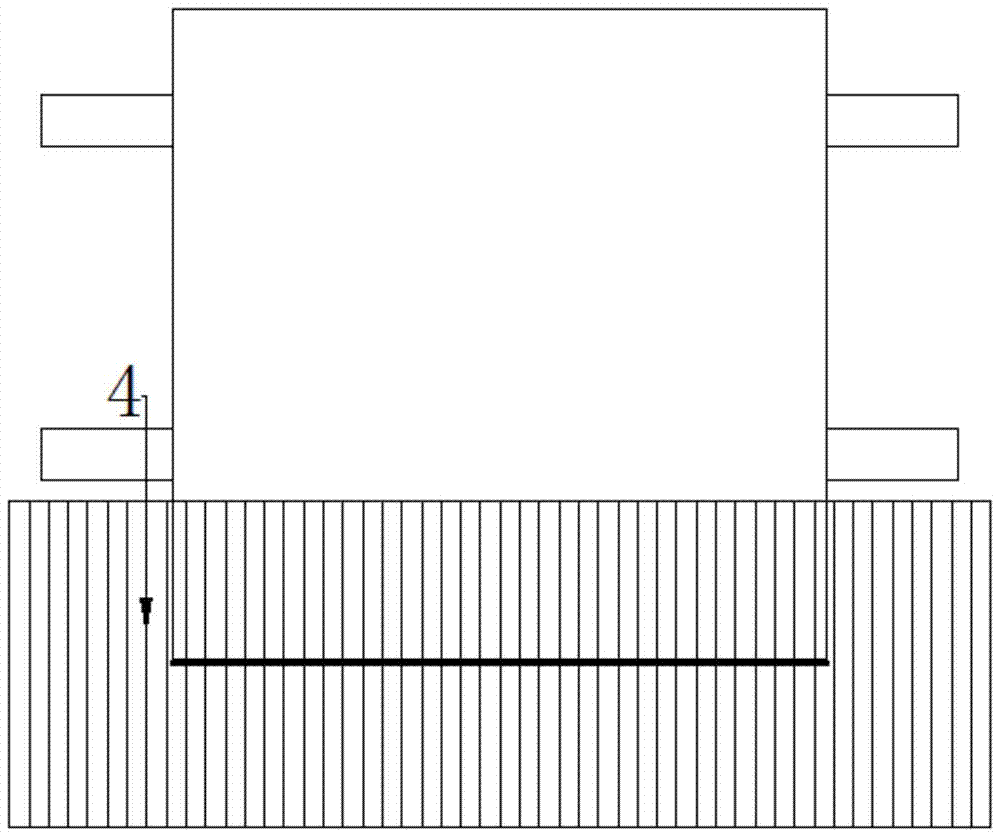

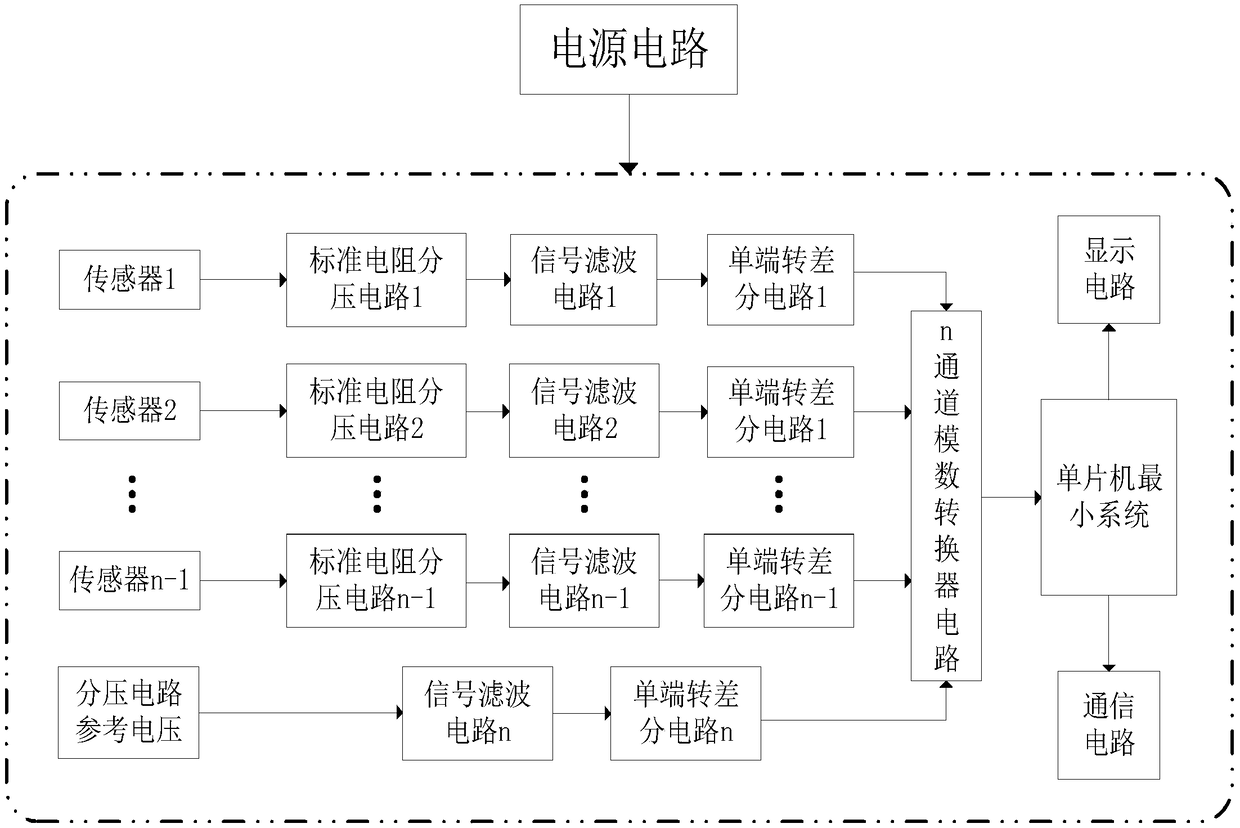

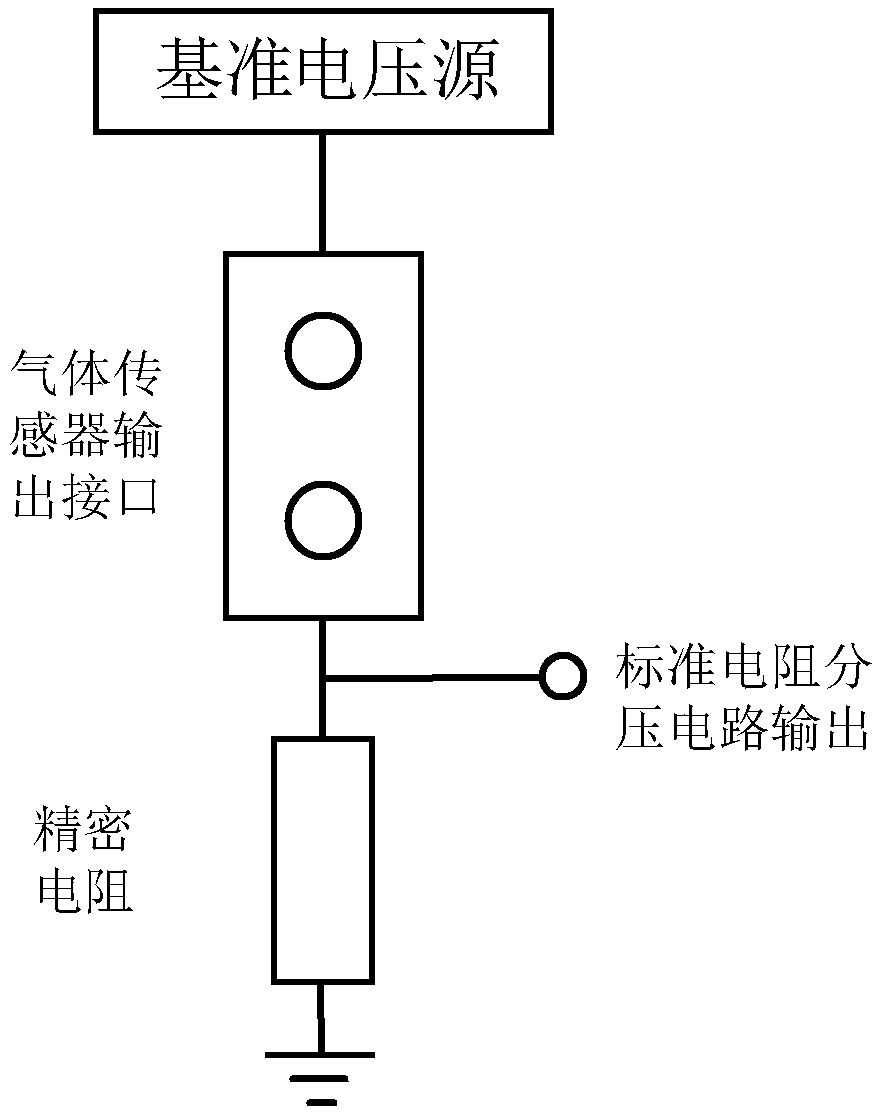

Detection system and detection method for output of gas sensor array based on single chip microcomputer

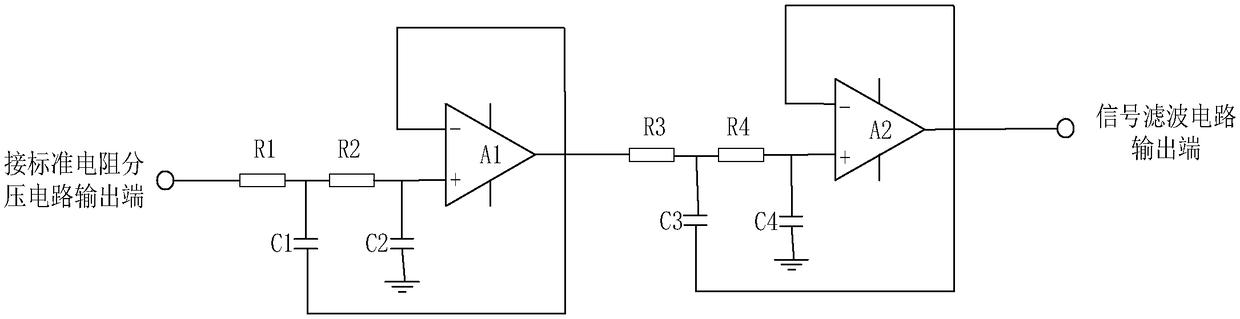

InactiveCN109342660ASuppresses high-frequency signal interference and common-mode interferenceImprove detection resolutionProgramme controlResistance/reactance/impedenceAnalog to digital conversionImage resolution

The invention discloses a detection system for the output of a gas sensor array based on a single chip microcomputer. The detection system comprises the analog circuit part and the digital circuit part; wherein the analog circuit part comprises a power supply module, a standard resistor division module, a signal filtering module, a single-ended to differential module, and an analog-to-digital conversion module; the digital circuit part comprises a single-chip microcomputer, a communication module, and a display module. The invention further discloses a detection method for the output of the gas sensor array based on the single chip microcomputer. According to the detection system and the detection method for the output of the gas sensor array based on the single chip microcomputer, the output of the sensor array can be detected online; the detection resolution is improved; and the detection result is displayed in real-time.

Owner:XI AN JIAOTONG UNIV

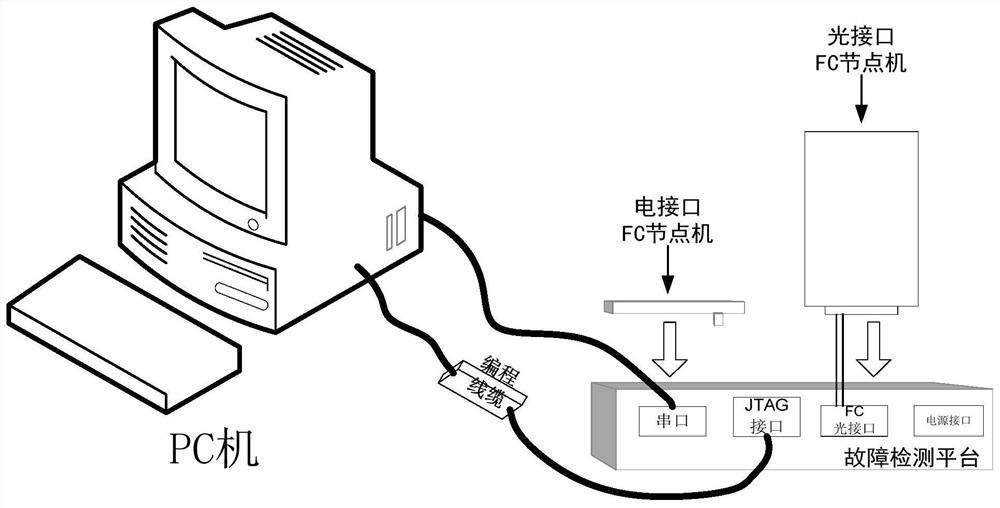

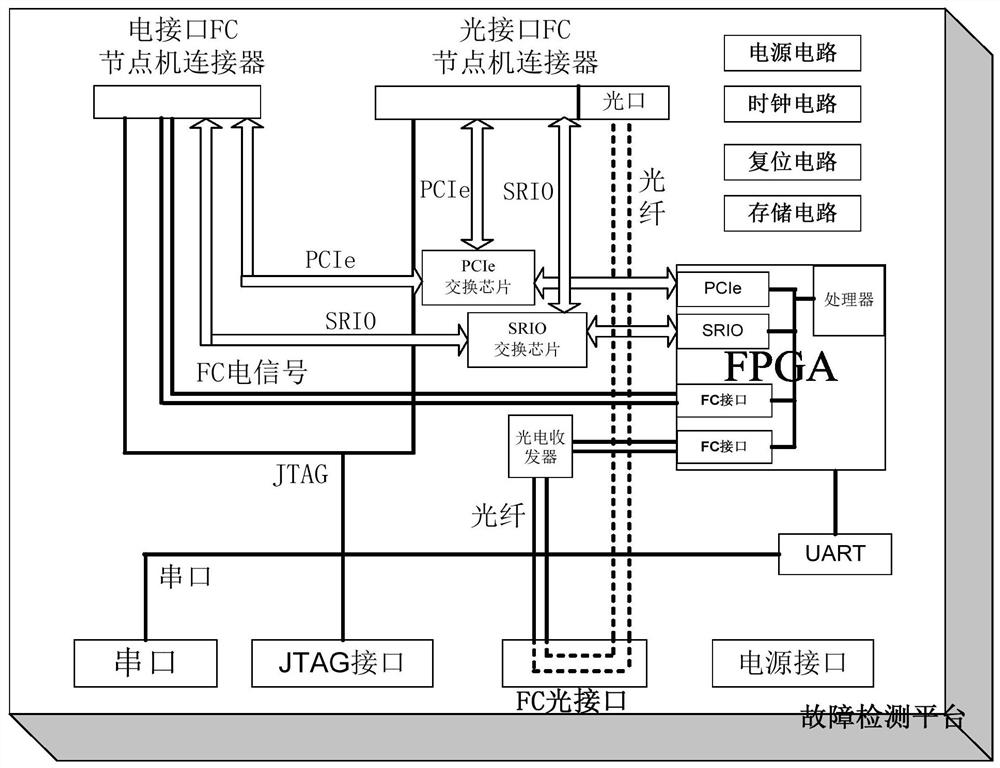

Fault detection platform of FC node machine with standard serial host interface

PendingCN112306773ARealize detectionEasy to operateDetecting faulty computer hardwareEmbedded systemMotherboard

The invention discloses a fault detection platform of an FC node machine with a standard serial host interface, and the platform comprises a detection platform motherboard and a detection platform structural member; the detection platform motherboard is arranged above the detection platform structural member, the detection platform motherboard is fixed by the detection platform structural member,and the detection platform motherboard is cooled; the detection platform motherboard comprises an external interface unit, a standard host interface unit, an FC interface unit, an FPGA with a built-inprocessor, and a processor circuit. The fault detection platform is used for testing various FC electrical interface node machines and optical interface node machines supporting PCIe host interfacesor SRIO host interfaces in two test modes, and the two test modes include an FC node machine opposite transmission test mode and an FC node machine surrounding test mode. The problems that an FC nodemachine of an existing standard serial host interface is complex in fault detection environment building, low in expandability and universality and the like are solved.

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com