Monorail contact type track detection vehicle

A track inspection vehicle and contact technology, which is applied in railway inspection vehicles, measuring devices, radio wave measurement systems, etc., can solve the problems of large equipment investment and increased cost of inspection vehicles, so as to improve work efficiency and achieve stable and reliable detection. , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

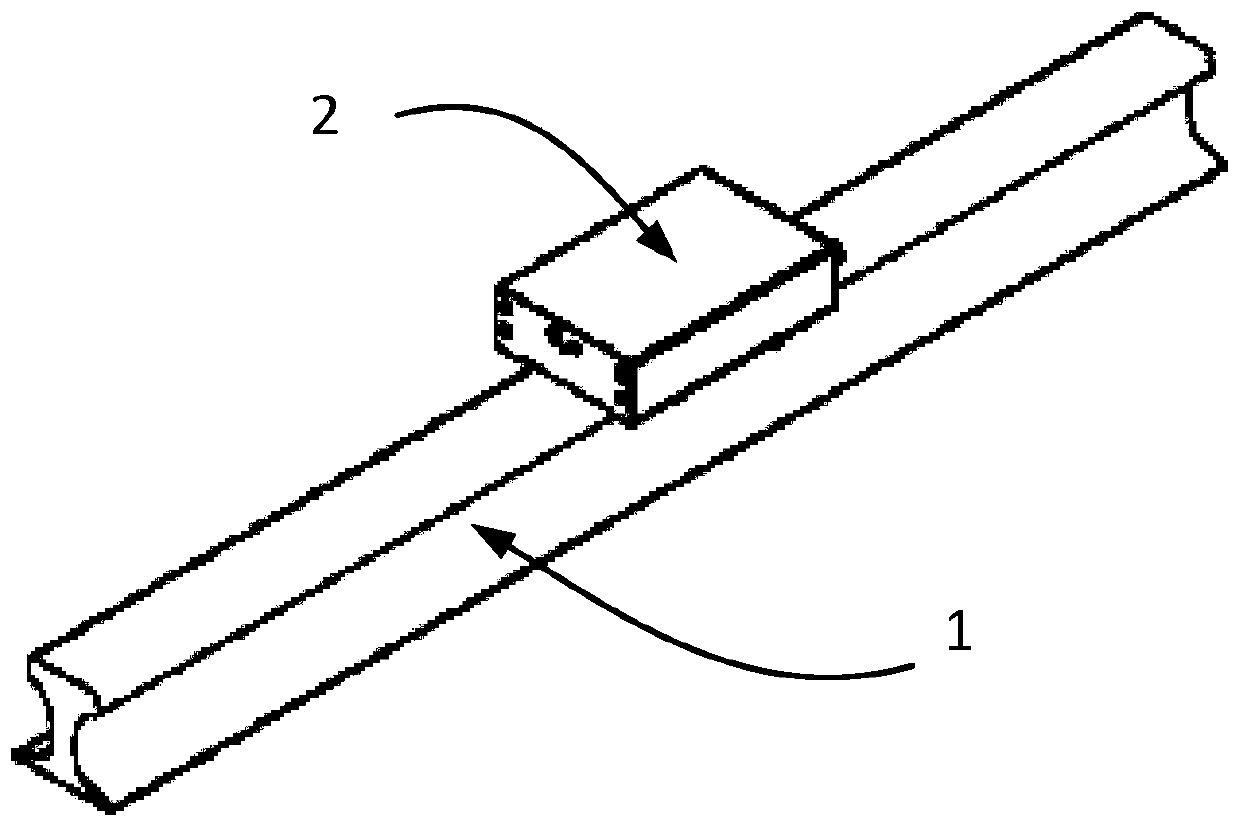

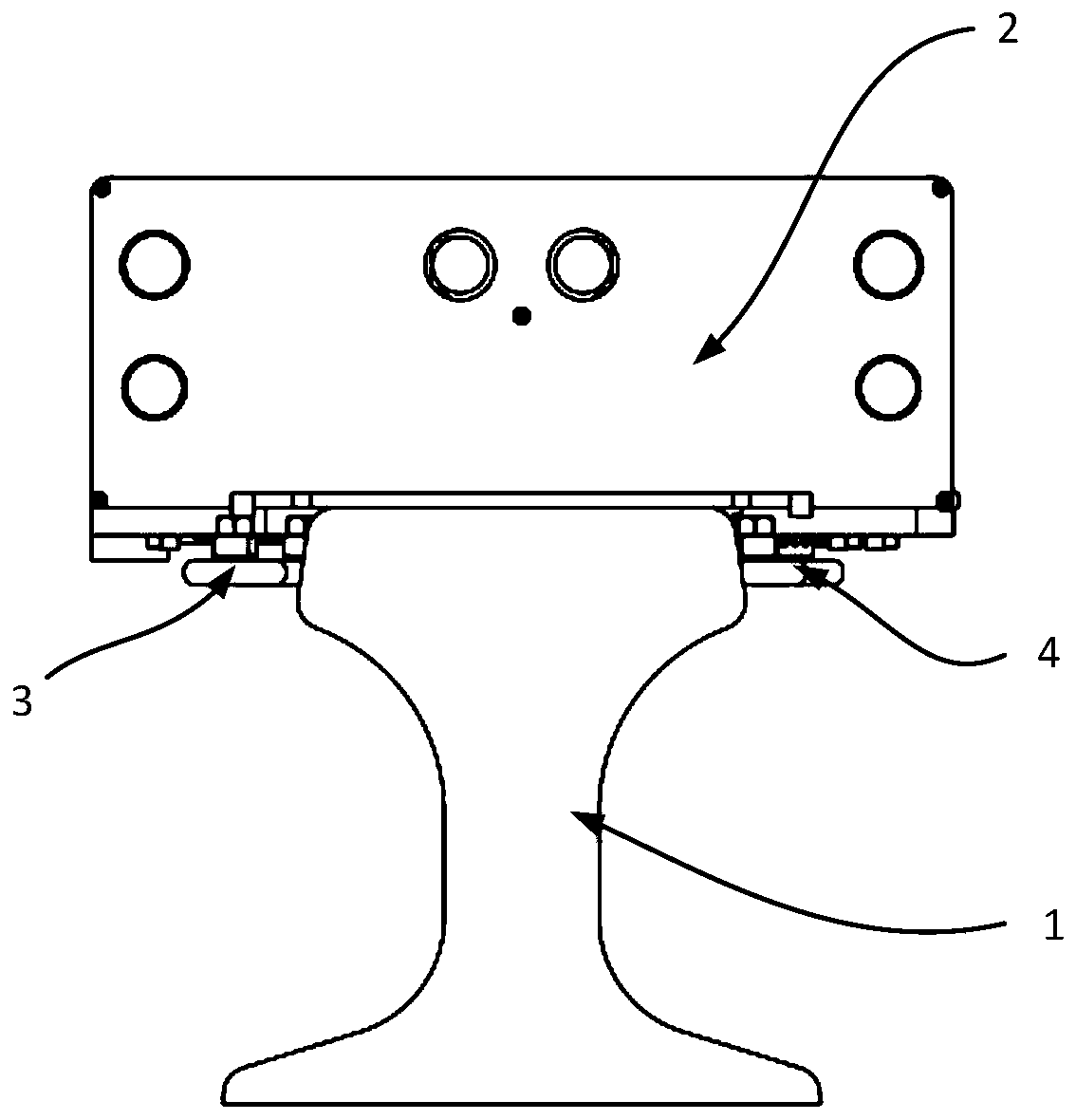

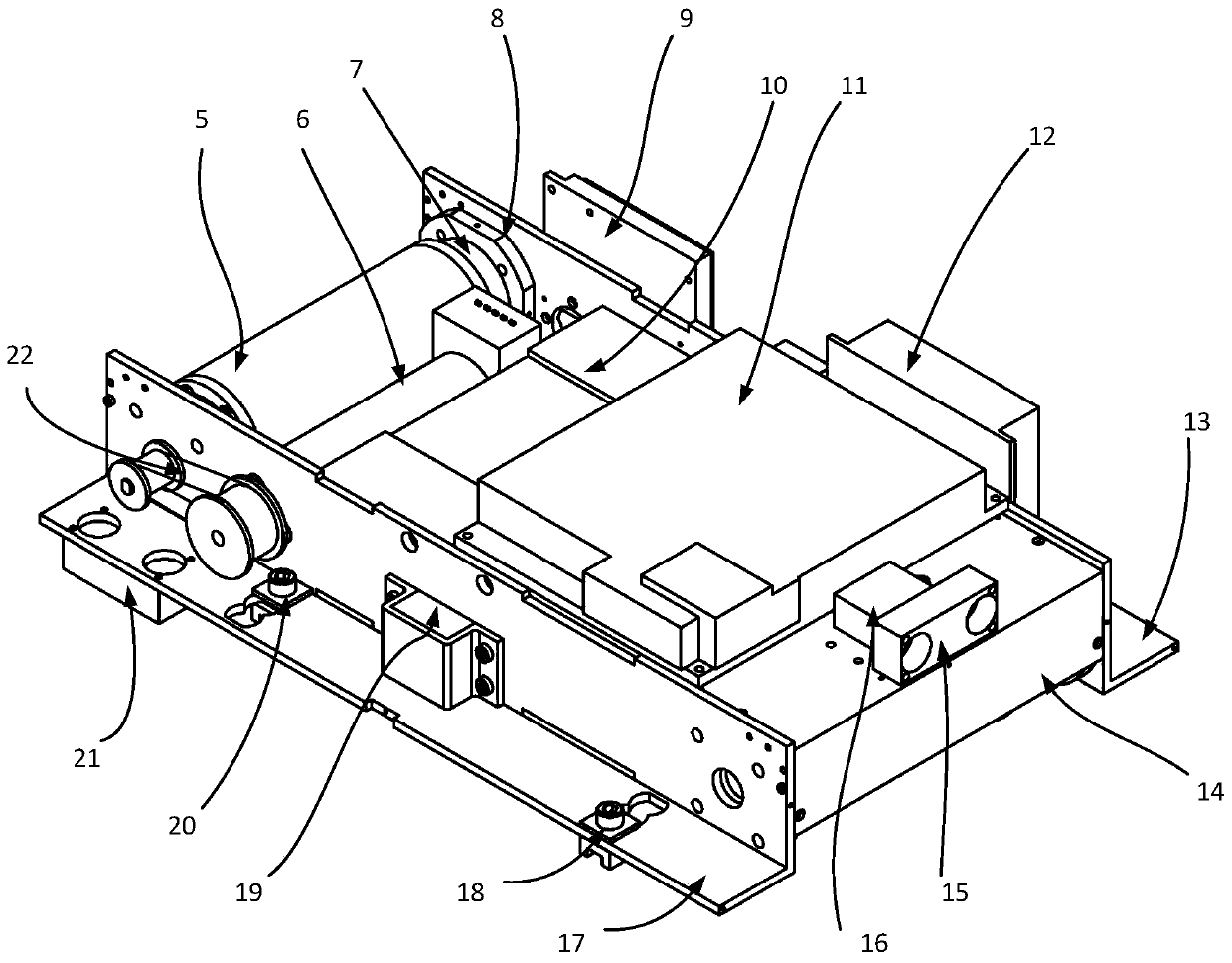

[0033] like Figure 1~3 As shown, a single-track contact type track detection car 2 includes: a car body; 3 ultrasonic sensors, respectively arranged at the front end, rear end and side of the car body; driving components, which are arranged on the car body, for driving the car body The body moves on the track; several pairs of guide wheels are arranged at the bottom of the car body, and each pair of guide wheels is respectively located on both sides of the track 1, and is close to the side of the track 1; lateral sensors 19, vertical sensors 16, control The device 9 and the signal processing unit 11 are arranged in the vehicle body, and the signal processing unit 11 receives signals from multiple ultrasonic sensors, vertical sensors 16 , and lateral sensors 19 and / or sends instructions to the controller 9 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com