Super-resolution defect detecting device and detecting method based on super-oscillation lens

A defect detection and super-oscillation technology, applied in the field of microscopic imaging and micro-nano optics, can solve problems such as insufficient resolution and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

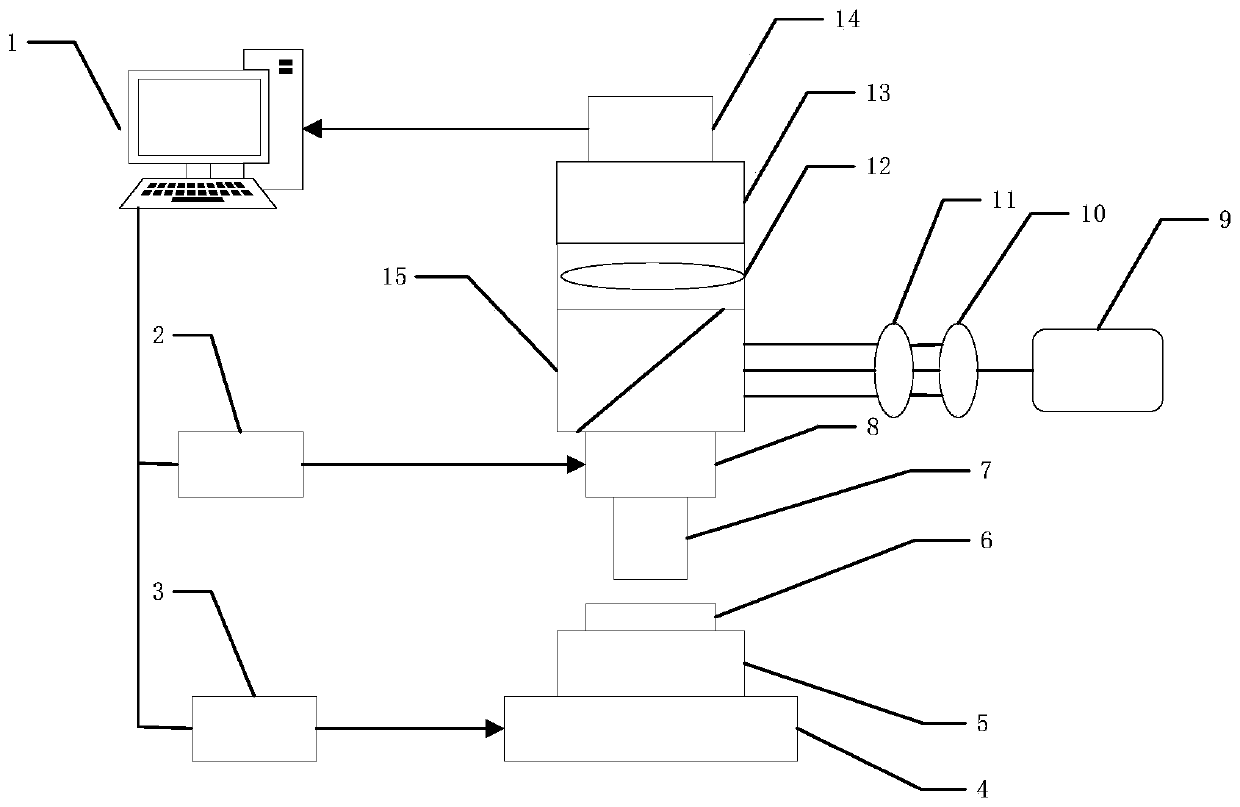

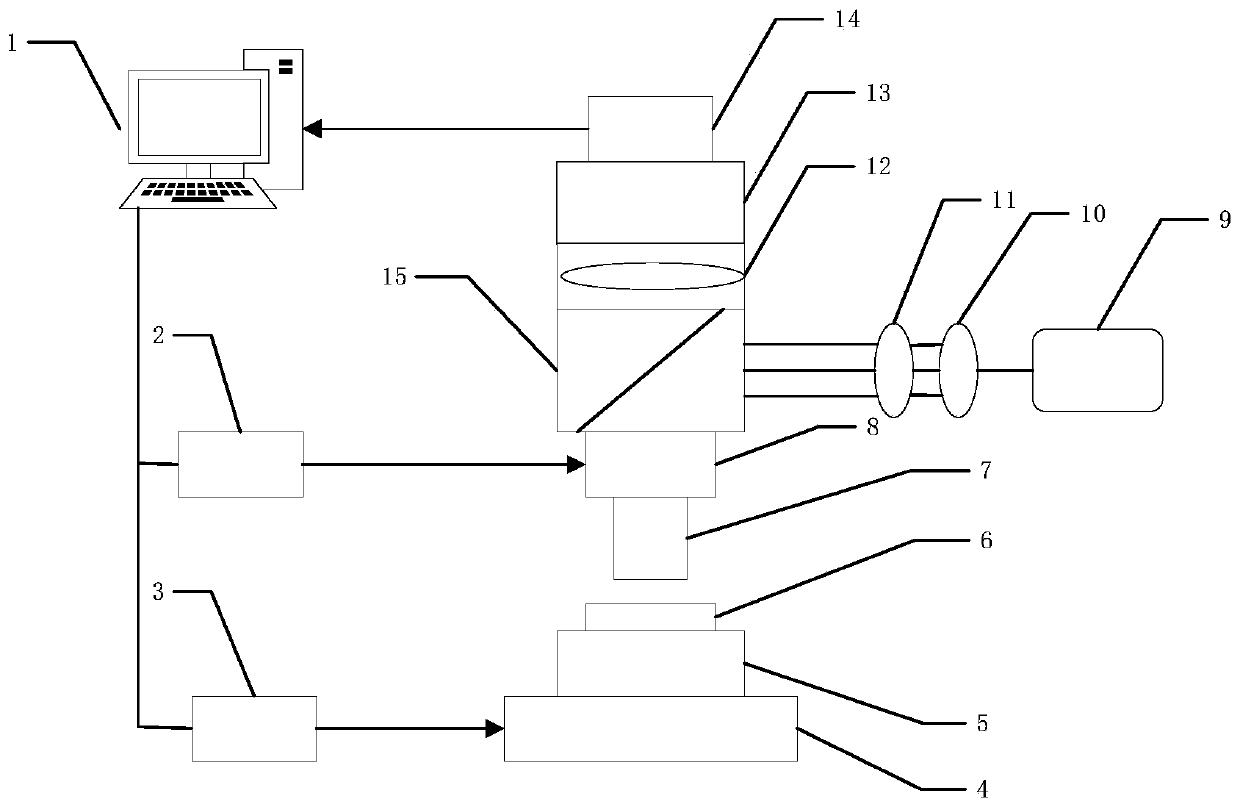

[0039] Example 1: Using an auto-focus defect detection device based on image information entropy and hill-climbing search algorithm to measure a substrate with a minimum defect size of 100 nm or less

[0040] 1. Build the optical path: such as figure 1 As shown, the laser light source 9 emits laser light with a wavelength of 532nm, which is collimated by the beam expander 10 and the collimator lens 11 and irradiates the semi-transparent and semi-reflective lens 15, and the laser beam reaches the objective lens 7 with a magnification of 50 times after being reflected. Irradiated to the substrate 6 adsorbed in the vacuum adsorption device 5, the light beam reflected by the substrate passes through the semi-transparent and semi-reflective lens 15, then passes through the specially optimized super-oscillating lens 12, and finally reaches the CCD 14 through the microscope body 13 to complete the image collected, and then transmitted to the host computer 1. Among them, the speciall...

Embodiment 2

[0045] Example 2: Using an auto-focus defect detection device based on the improved point sharpness algorithm and hill-climbing search algorithm to measure a substrate with a minimum defect size of 100 nm or less

[0046] 1. If figure 1 As shown, the laser light source 9 emits the laser beam, reaches the semi-transparent lens 15 through the beam expander 10 and the collimator lens 11, and reaches the substrate 6 surface through the semi-transparent lens 15 and the objective lens 7, and the substrate 6 surface reflection The returned light passes through the semi-transparent and semi-reflective lens 15 again, and then transmits to the specially optimized super-oscillating lens 12 , and finally the digital image of the substrate 6 is collected by the CCD 14 in real time.

[0047] 2. Coarse focusing process: Still use the linear motor to drive the linear motor with the driver program in the upper computer 1, and use the image collected by the CCD to analyze, according to the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com