System for detecting defects of filter paper based on machine vision technology and detection method thereof

A technology of machine vision and defect detection, which is applied in the direction of optical testing for defects/defects, can solve the problems of poor imaging quality, low efficiency, and poor defect recognition ability of the optical system, and achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

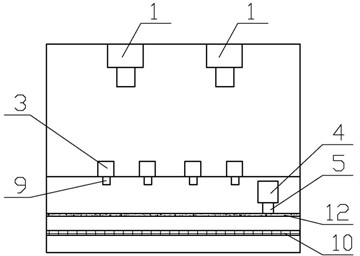

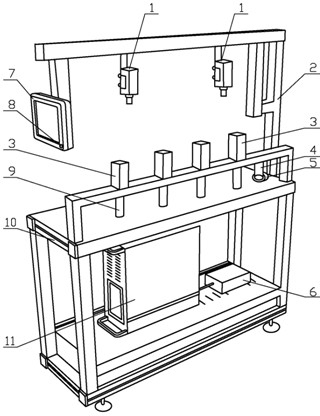

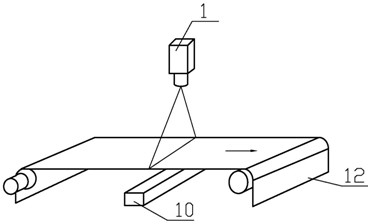

[0030] Such as Figure 1-4 Shown, the present invention comprises frame 2, machine vision device, industrial computer 11 and defect mark printer; Machine vision device comprises light source 10 and several high-speed cameras 1; Industrial computer 11 comprises the central microprocessor of built-in embedded image processing software , Display 7; defect mark printers include encoder 4 and several defect mark printers. The high-speed camera 1, the encoder 4, the display 7 and the defect mark printer are all connected with the central microprocessor of the industrial computer 11. The light source adopts LED or other linear light sources, and is arranged under the panel of the rack 2 . The high-speed camera 1 adopts a line array or area array CCD camera, is fixed on the upper cross bar of the frame 2, and communicates with the industrial computer through the interface provided on the high-speed camera; the industrial computer host is arranged on the bottom plate of the frame 2; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com