Flying drone engine's sleeving size and geometrical error detection device

A geometric error and detection device technology, applied in the direction of measuring devices, electromagnetic measuring devices, and electrical devices, can solve problems such as low production efficiency and poor follow-up on the production site, so as to improve the scope of application, ensure accuracy, and improve detection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] This embodiment is a device for detecting the size and geometric error of the collar of the UAV engine.

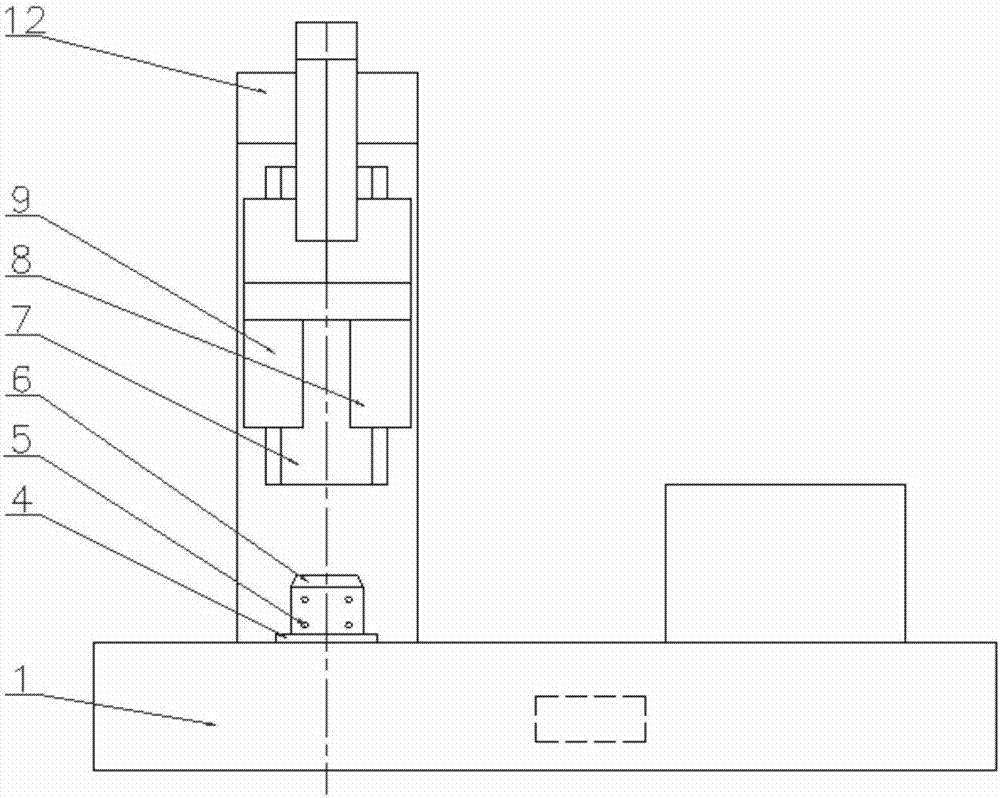

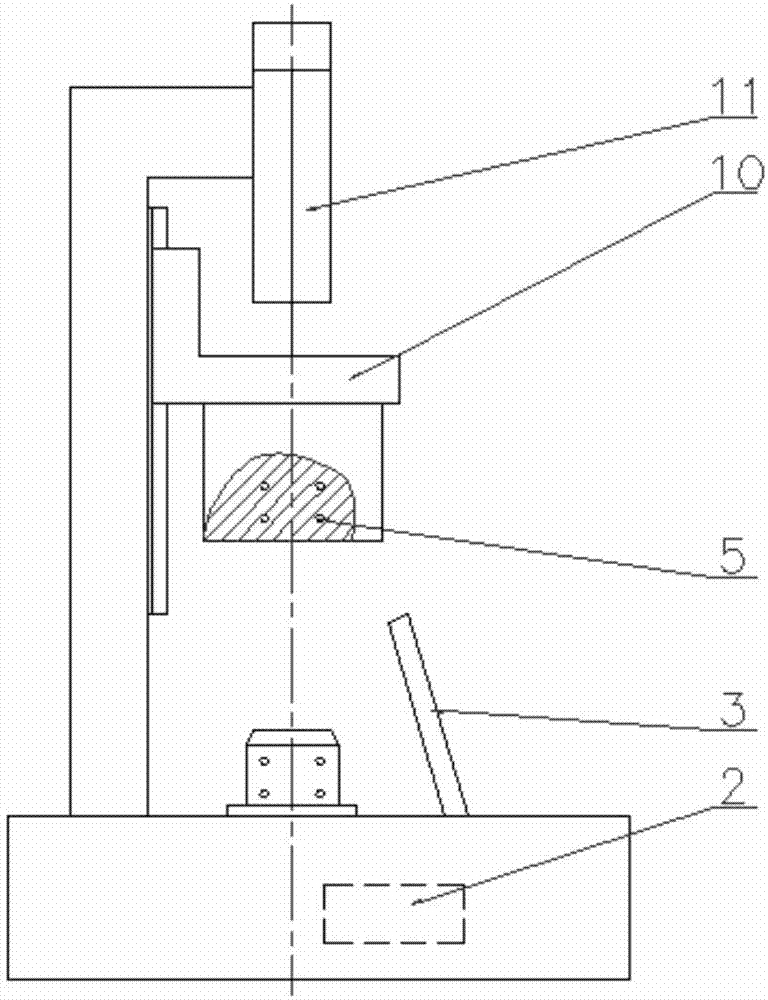

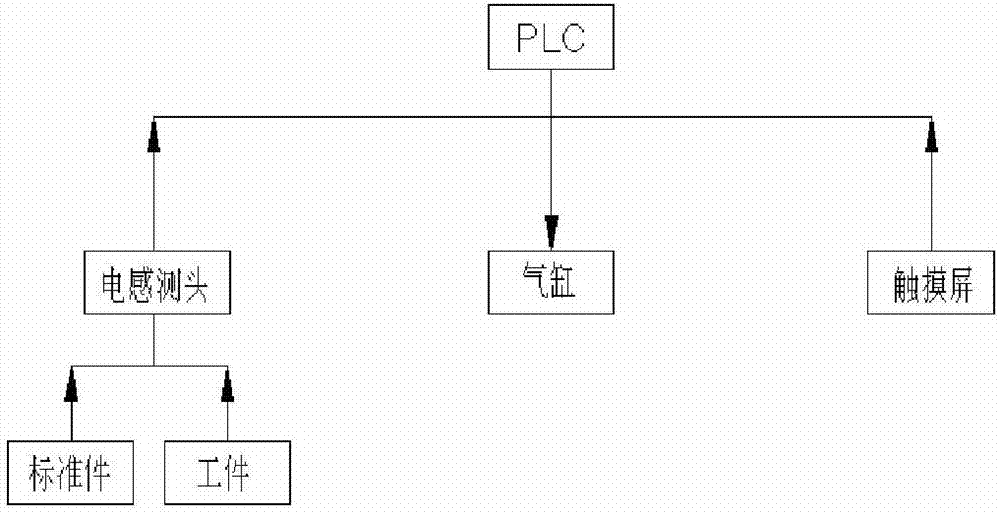

[0019] refer to Figure 1 to Figure 5 , the present embodiment unmanned aerial vehicle engine collar dimension, the geometrical error detecting device, by base 1, programmable controller 2, touch screen display 3, positioning ring 4, inductive sensor measuring head 5, inner measuring base column 6, guide rail 7 , the first measuring base block 8, the second measuring base block 9, the sliding block 10, the cylinder 11, the bracket 12 and independent standard parts; the programmable controller 2 is installed inside the base 1, and the bracket 12 is vertically fixed on the base 1, the touch screen display 3 is fixed on the base 1 on the side of the bracket 12. The guide rail 7 is fixed on the inner side of the bracket 12, the sliding block 10 is installed in cooperation with the guide rail 7, and the first measuring base block 8 and the second measuring base block 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com