Intelligent detection device and method for compressor stator guide vane setting angle

The technology of a guide vane and a detection method is applied in the field of intelligent detection of the installation angle of the guide vane of the stator of the compressor, which can solve the problems of inconvenient and intelligent use, low accuracy and the like, and achieve high measurement accuracy, high efficiency and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

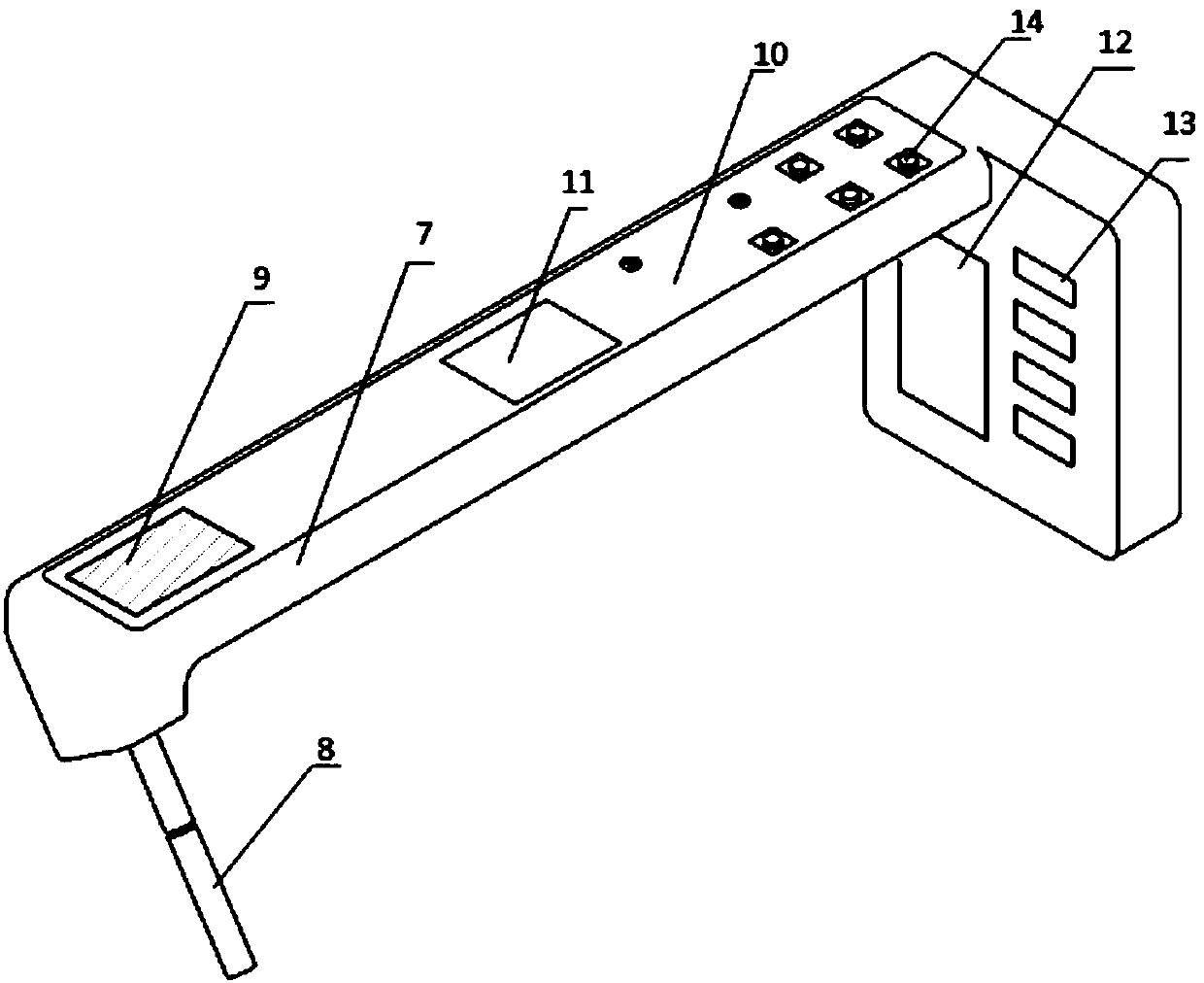

[0022] The radial distance of the inclinometer described in this embodiment is 260 mm for the 0-stage blade, 240 mm for the 1-stage blade, 230 mm for the 2-stage blade, and 226 mm for the 3-stage blade.

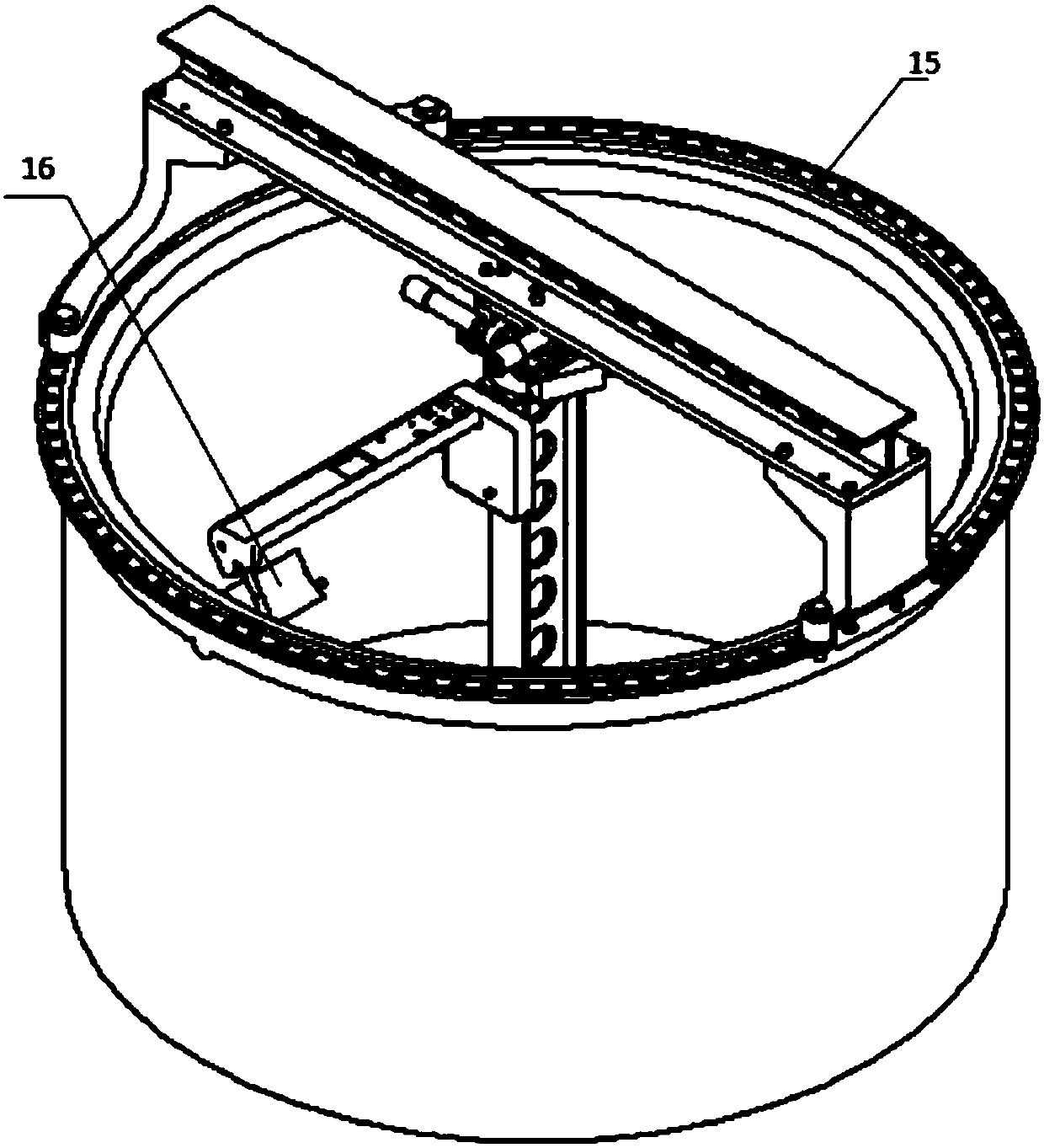

[0023] The number of stages of blades in the casing described in this embodiment is 4, and each stage has 100 blades.

[0024] Such as Figure 1-4 As shown, the steps of the method for detecting the installation angle of the compressor stator guide vane described in this embodiment are:

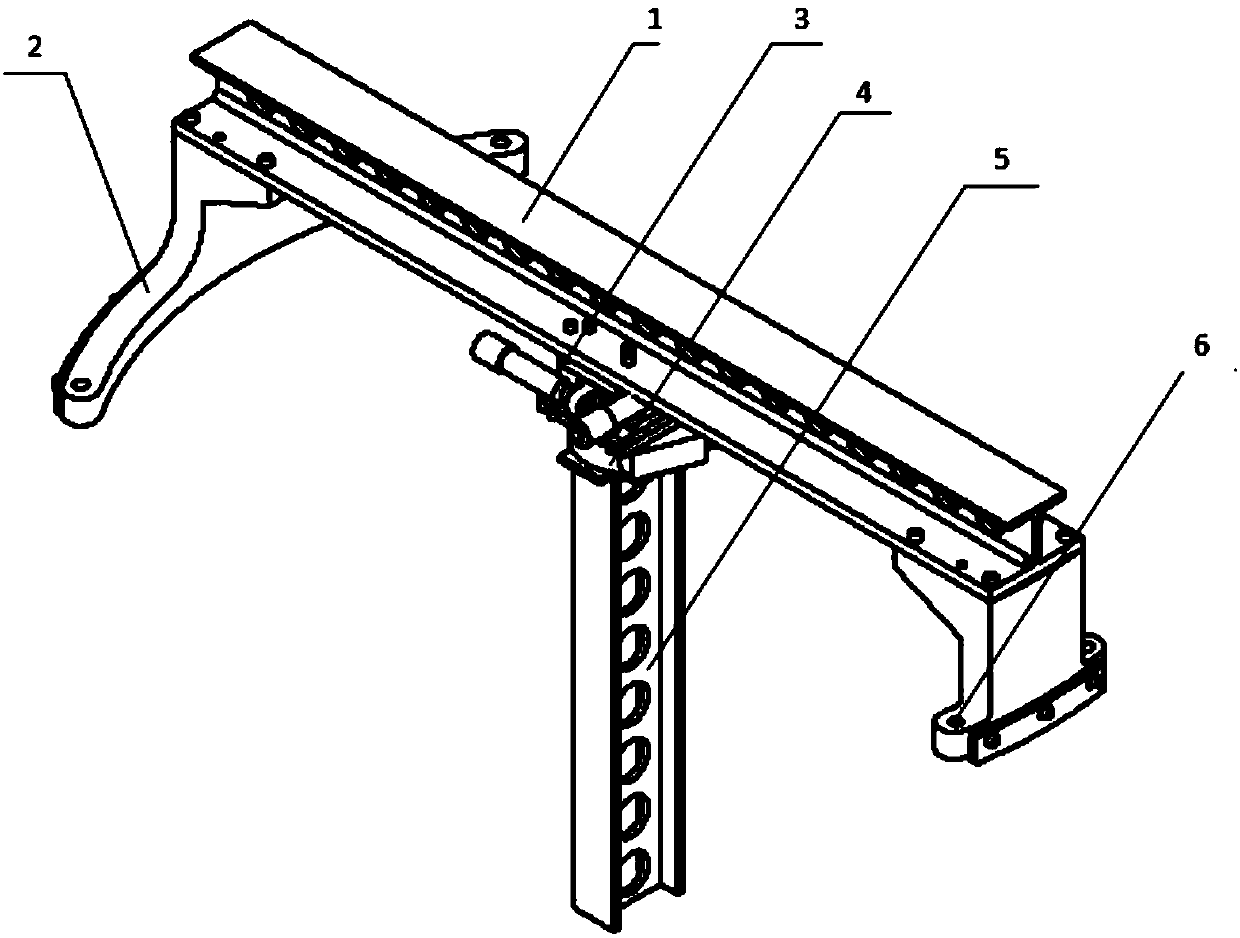

[0025] 1. Fix the special measuring and positioning tool on the upper end surface of the compressor casing 15 to be tested through the positioning pin 6, attach the magnetic gauge frame to the depth axis 5 of the measuring tool, and rotate through the high-precision turntable 4 in the center of the measuring tool Drive the dial indicator to beat the outer circle of the casing 15, adjust the two-dimensional sliding table 3 on the center of the measuring tool, and find the axis of the casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com