Tightness self-regulating rotating mechanism of bearing performance precision detection instrument

A technology of bearing performance and rotating mechanism, applied in the direction of mechanical bearing testing, etc., can solve the problems of increasing failure rate, complicated connecting device, low detection accuracy, etc., to eliminate the influence of human factors, reduce labor intensity, and improve the effect of detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

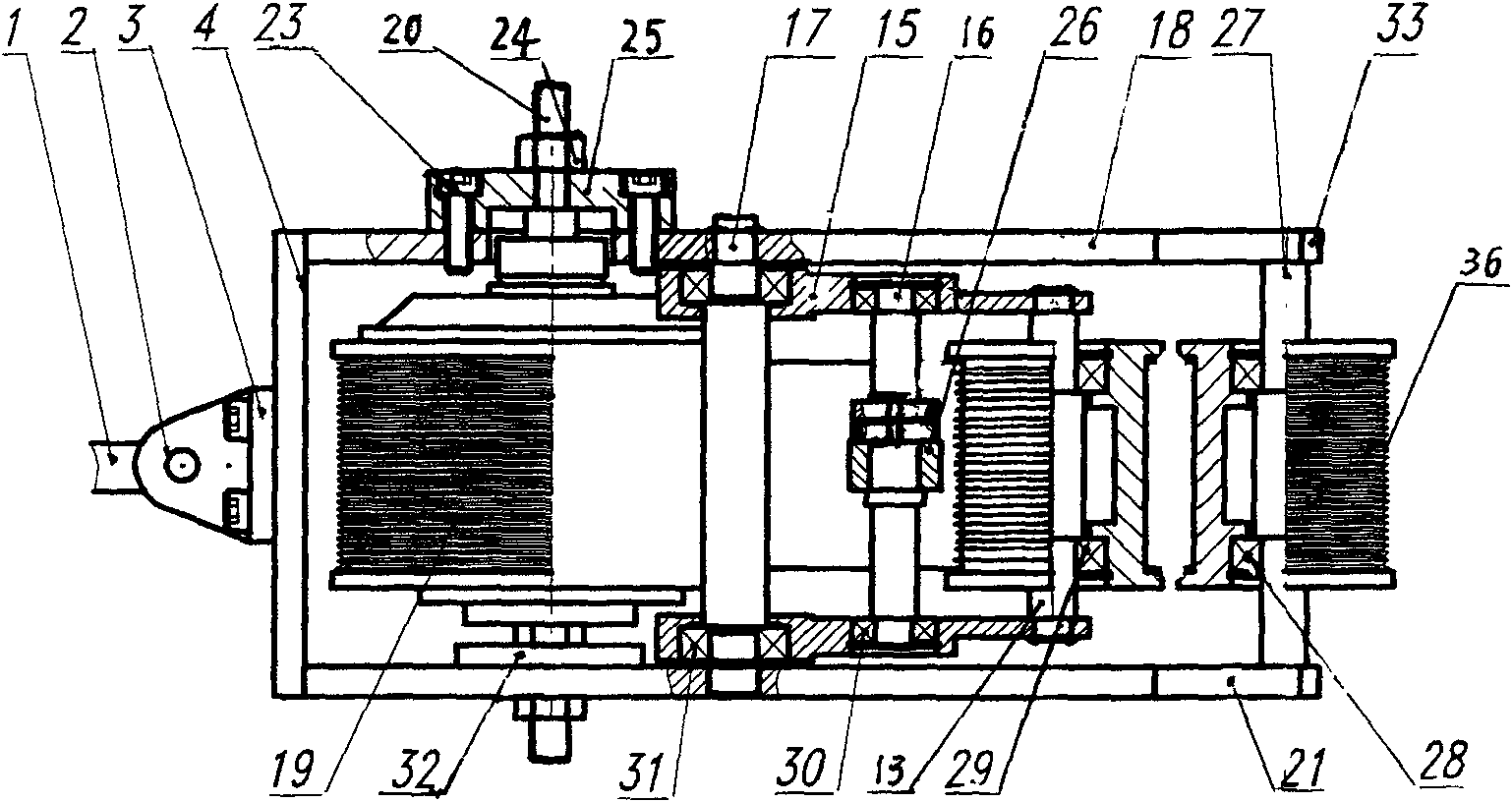

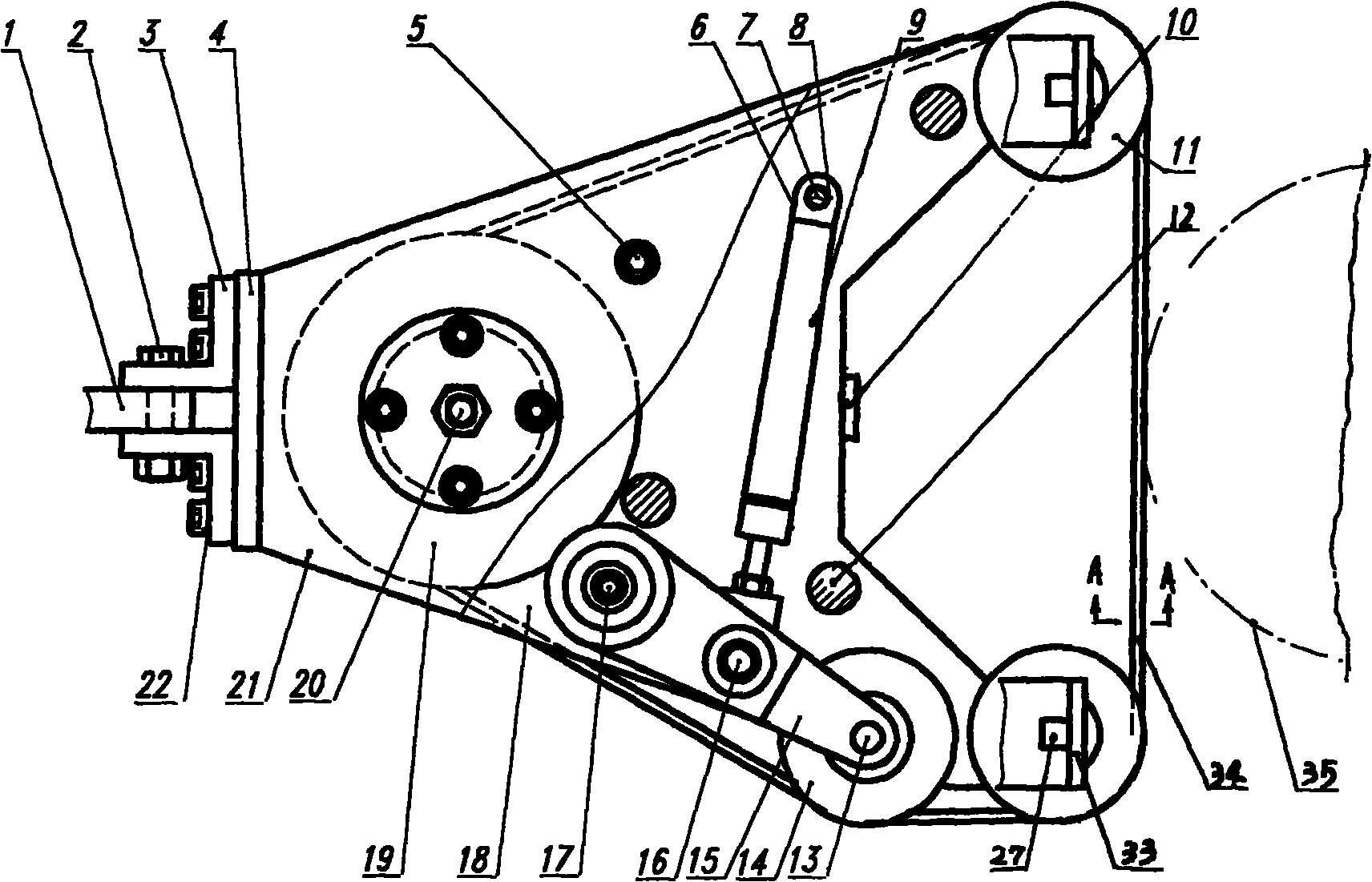

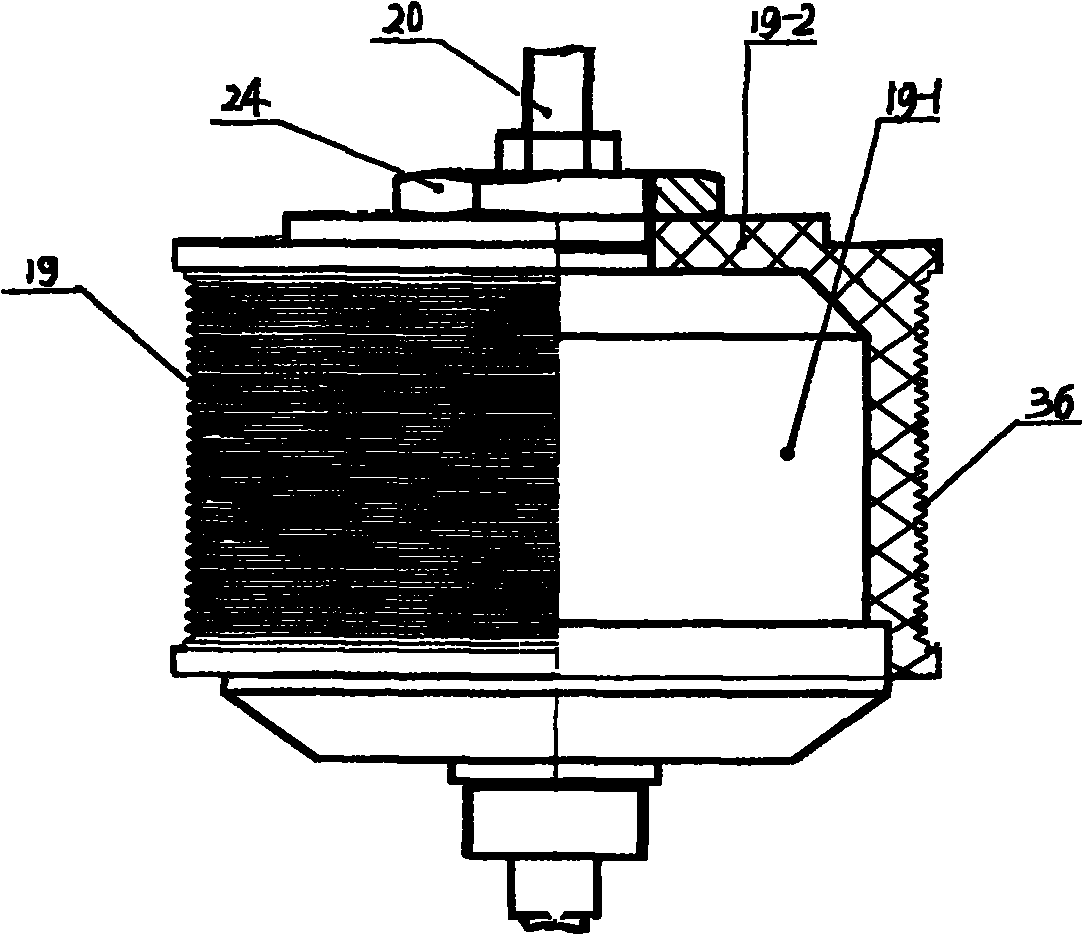

[0013] Embodiment, with reference to the accompanying drawings, a bearing performance precision tester tightness self-adjusting rotating mechanism, including a DC brushless motor 19-1 and a tension gas spring 9, which is characterized in that the DC brushless motor 19-1 and the driving wheel 19 -2 is fixed together, and the driving wheel 19-2 is movably contained on the driving wheel shaft 20, and the driving wheel shaft 20 is fixedly mounted on the left clamping plate 18 and the right clamping plate 21, with three positioning shafts 12 between the left clamping plate 18 and the right clamping plate 21 Connect and locate with a support rod 5, and a positioning plate 10 is housed in the middle, and the left clamping plate 18 and the right clamping plate 21 right end are fixedly equipped with a driven shaft 27 up and down, and a driven wheel is movably equipped with a bearing 28 on the driven shaft 27 11; a centering shaft 17 is also fixedly installed in the left clamping plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com