Machine vision-based defect detection method of chemical fiber spinning nozzle hole

A technology of machine vision and detection method, applied in the direction of optical testing flaws/defects, instruments, measuring devices, etc., can solve the problems of low detection efficiency, high detection cost, small diameter of spinneret, etc., to reduce labor intensity and ensure accurate The effect of improving the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

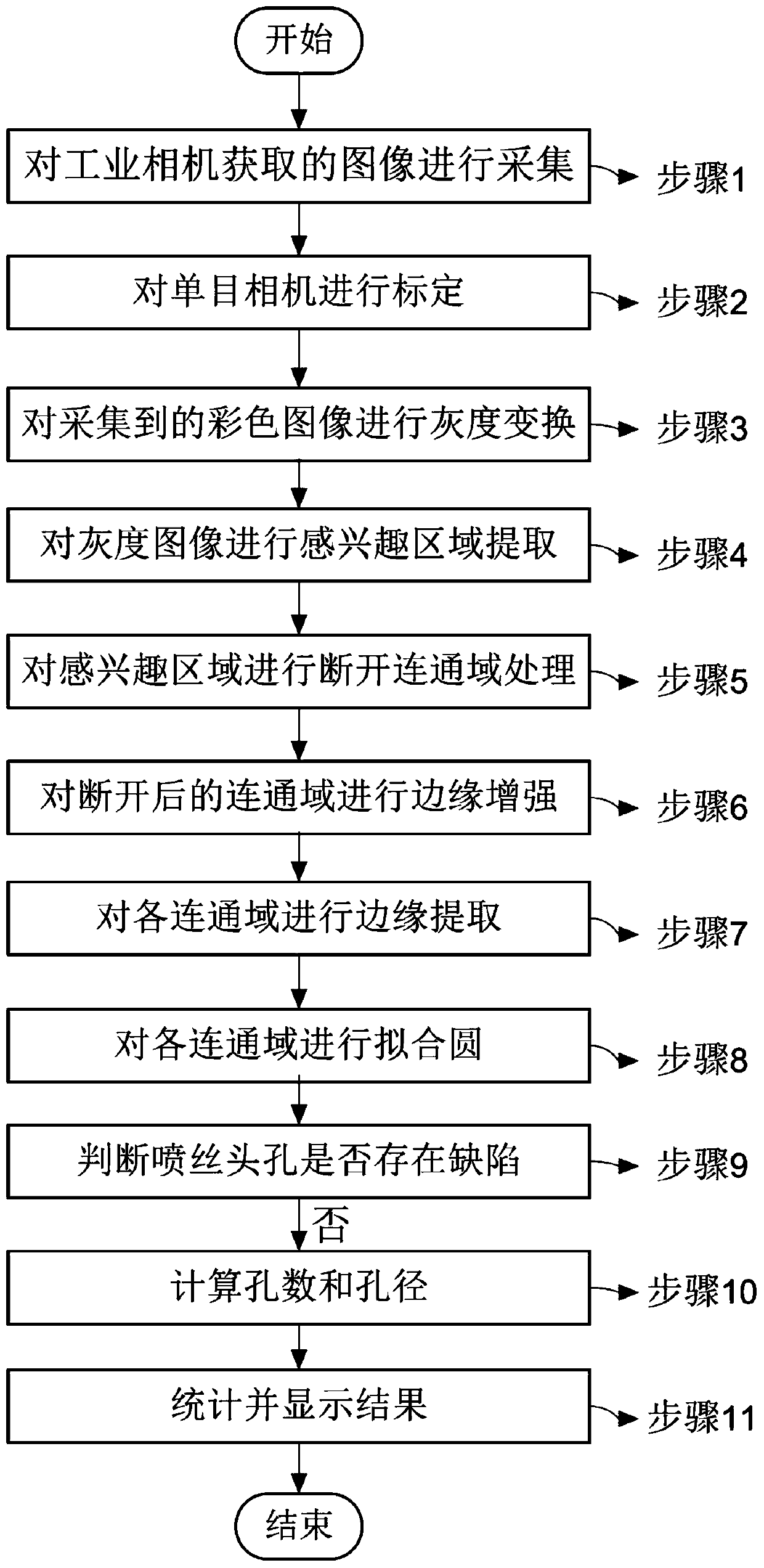

[0033] This embodiment provides a method for detecting defects in the hole of a chemical fiber spinneret based on machine vision, such as figure 1 As shown, it is characterized in that it includes the following process steps:

[0034] Step 1. Collect the images acquired by the industrial camera;

[0035] Step 2. Calibrate the camera to obtain the relationship between pixel size and actual size;

[0036] Step 3. Carry out grayscale transformation to the collected color image;

[0037] Step 4. Carry out region of interest (Regions of Interest, ROI) extraction to the image after carrying out gray-scale transformation;

[0038] Step 5. Disconnect connected domain processing to the extracted ROI region;

[0039] Step 6. Carry out edge enhancement to the disconnected connected domain;

[0040] Step 7. Carry out edge extraction to each connected domain;

[0041] Step 8. Carry out fitting circle to each connected domain;

[0042] Step 9. Determine whether there is a defect, if n...

Embodiment 2

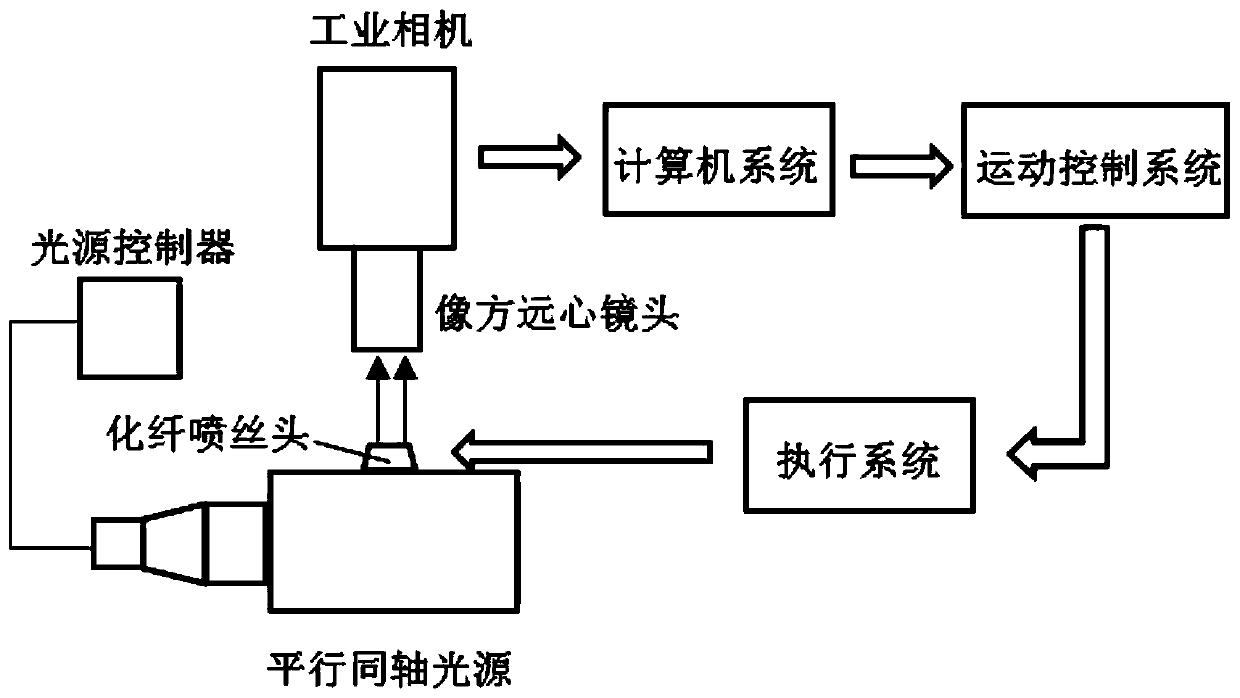

[0069] This embodiment provides a machine vision-based chemical fiber spinneret hole defect detection system, such as image 3As shown, it is characterized in that it includes the following process steps:

[0070] The light source lighting system is used to provide the light conditions required for image acquisition;

[0071] An image acquisition system, used for acquiring images and processing the images;

[0072] A computer system for image processing and display of test results;

[0073] Motion control and communication system to synchronize with the production line and trigger the camera to take pictures;

[0074] Execution system for pick-up and transfer of spinnerets.

[0075] Specifically, generally speaking, the longer the wavelength, the greater the diffraction of light, so the present invention uses a coaxial backlight with a shorter wavelength.

[0076] Specifically, since the detection target is a hole with a diameter of 50-70um, parallel coaxial backlight illu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com