Scratch detection method on raw silicon wafer surface based on machine vision

A machine vision, silicon wafer surface technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of reducing production efficiency, debris, human factors can not be ignored, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

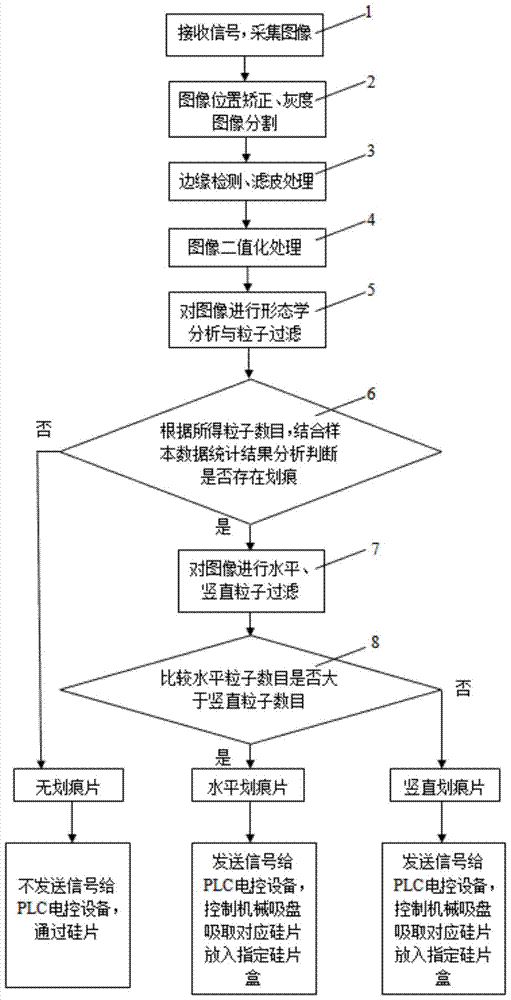

[0054] Such as figure 1 Shown, the surface scratch detection method of the raw material silicon wafer based on machine vision, comprises the following steps:

[0055] Step 1: Receive the signal and collect the image, which includes:

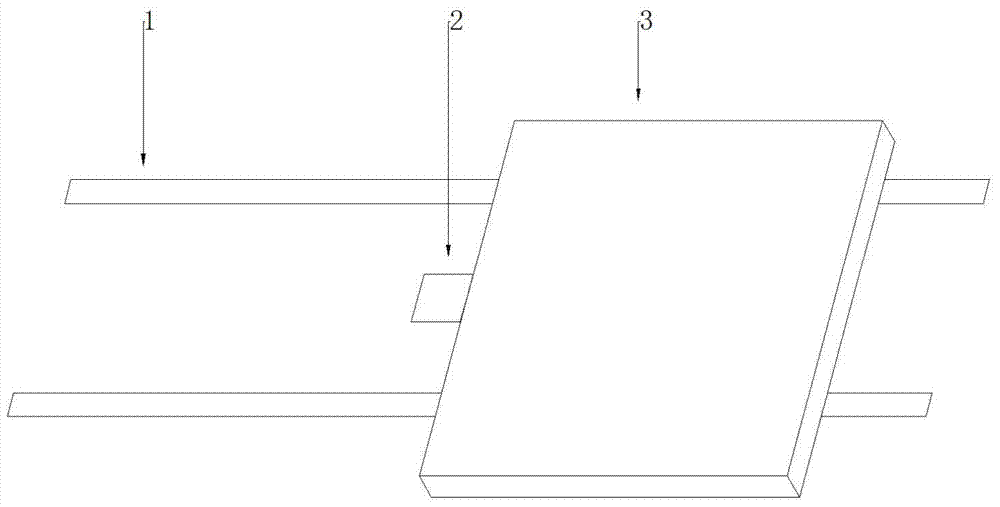

[0056] Step 1-1, such as figure 2 The white conveyor belt 1 shown, the photoelectric sensor 2, and the raw silicon wafer 3; the raw silicon wafer is sent to figure 2 The position shown covers the photoelectric sensor, and the sensor sends an analog signal to the data acquisition device, which is converted into a digital signal by the acquisition card and transmitted to the system;

[0057] Step 1-2: After receiving the acquisition signal, the system triggers the camera, acquires the image, and transmits the acquired color image of the raw silicon wafer to the image processing module;

[0058] Step 2: Perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com