Lower-contact type metro contact rail detecting system

A track detection and detection system technology, which is applied in the direction of railway vehicle shape measuring devices, measuring devices, railway car body parts, etc., can solve problems such as inability to realize off-line analysis and prediction, non-recording of detection data, and problems with brackets, etc., to improve The effect of management level and work efficiency, fast response speed, and avoiding the influence of accidental errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

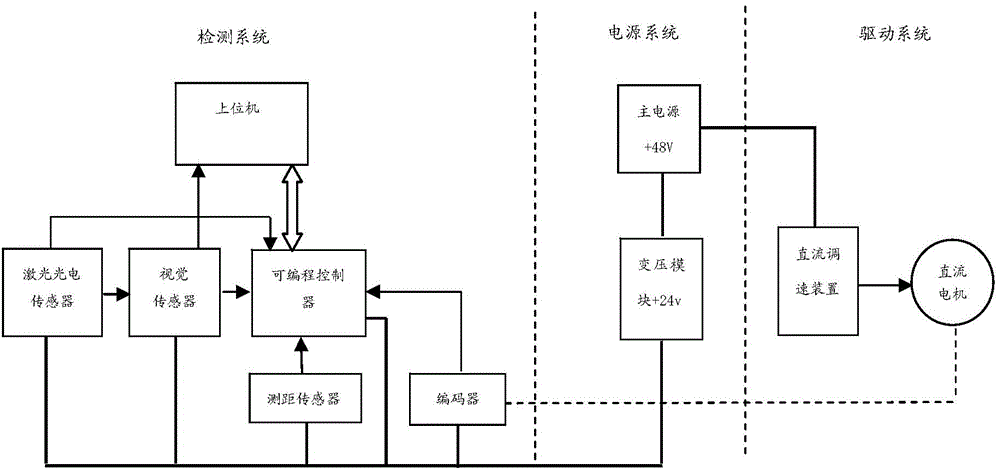

[0016] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as figure 1 As shown, a lower-contact subway contact rail track detection system includes a ring encoder, a laser photoelectric sensor, a visual sensor, a laser ranging sensor, a host computer, and detection software. Through signal collection, transmission, storage, and analysis, the Display the detection result. When the detection vehicle moves, the encoder sends out displacement pulses, and the programmable controller reads the encoded position information in real time and transmits it to the host computer to record the running distance or position of the detection vehicle; the laser photoelectric sensor finds the position of the bracket and sends out a pulse signal , trigger the visual sensor to take picture information of the bracket, and trigger the programmable controller to read the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com