Judging method for speed changing box clutch faults

A fault judgment and clutch technology, which is applied in machine gear/transmission mechanism testing, etc., can solve problems such as difficult maintenance, low clutch pressure of gearboxes, affecting equipment start-up rate and production tasks, etc., so as to reduce the difficulty of judgment and improve efficiency and quality , Improve the effect of contact performance and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

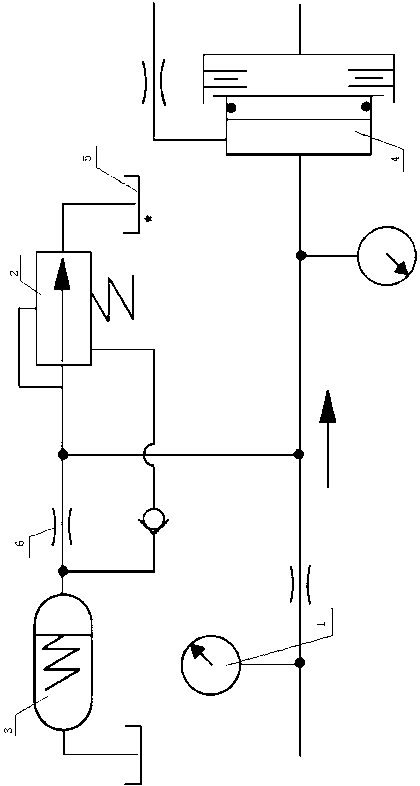

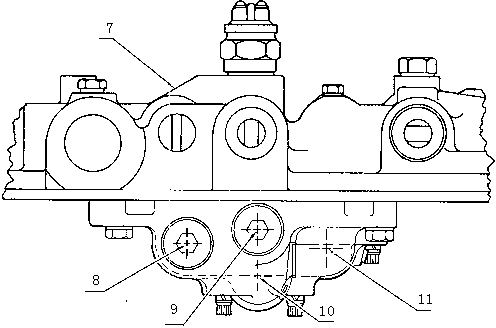

[0026] Such as Figure 2 to Figure 4 As shown, taking the gearbox produced by CLARK Company of the United States, such as the CLARK R33000 series used in the LH410 diesel scraper as an example, the tool pin 12 with a diameter of 9.5 mm and a length of 28.57 mm is processed, and the end of the tool pin 12 in contact with the shock valve is processed. There is a 45 degree chamfer. Connect the pressure gauge 1 with a range of 0.00-2.50Mpa to the pressure measuring joint on the control cover plate 7 of the gearbox. The measurement accuracy of the pressure gauge 1 is 0.01MPa. The gear pressure difference is within 0.03Mpa, but the system pressure is lower than 1.4Mpa. Disassemble the control cover plate 7, take out the buffer control valve spool and spring, install the tool pin 12 to block the limit of the buffer valve, so that it cannot change direction. Install the buffer valve plug, install the control cover, restart the equipment, switch the gears and observe the pressure ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com