Loading device applicable to space specially-shaped column node test

A technology of loading device and special-shaped column, which is applied in the direction of measuring device, machine/structural component test, instrument, etc., can solve the problem of lack of research on space nodes, and achieve the effect of strong applicability and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to more clearly illustrate the technical solutions and advantages of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings in the embodiments; the embodiment described in the application is only a form of the present invention, and no creative work Other embodiments all fall within the scope of protection of the present invention.

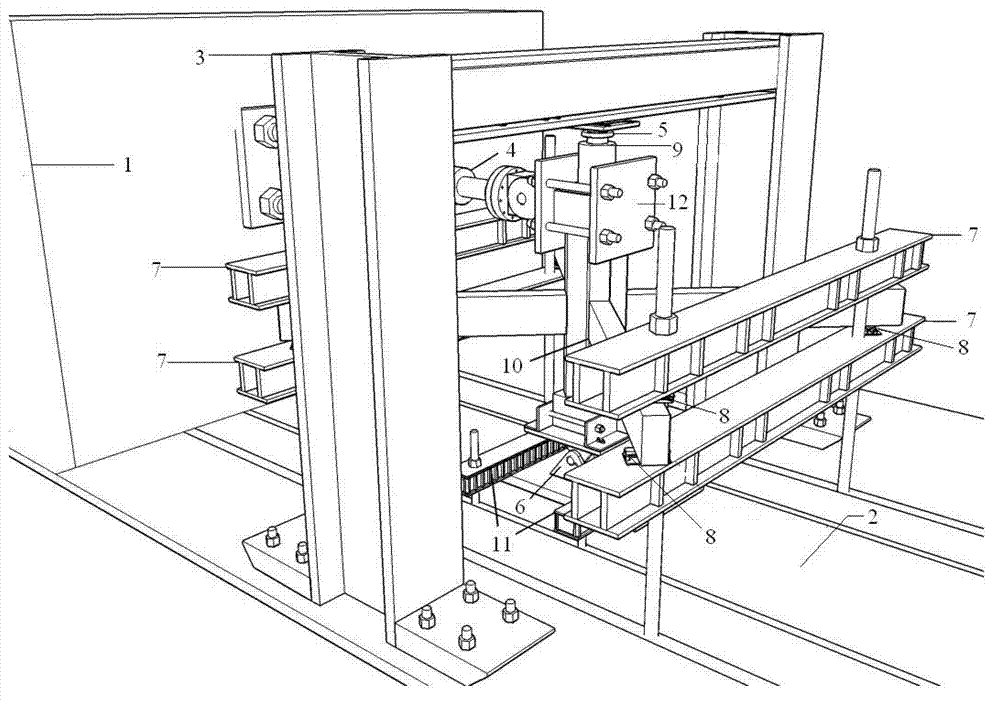

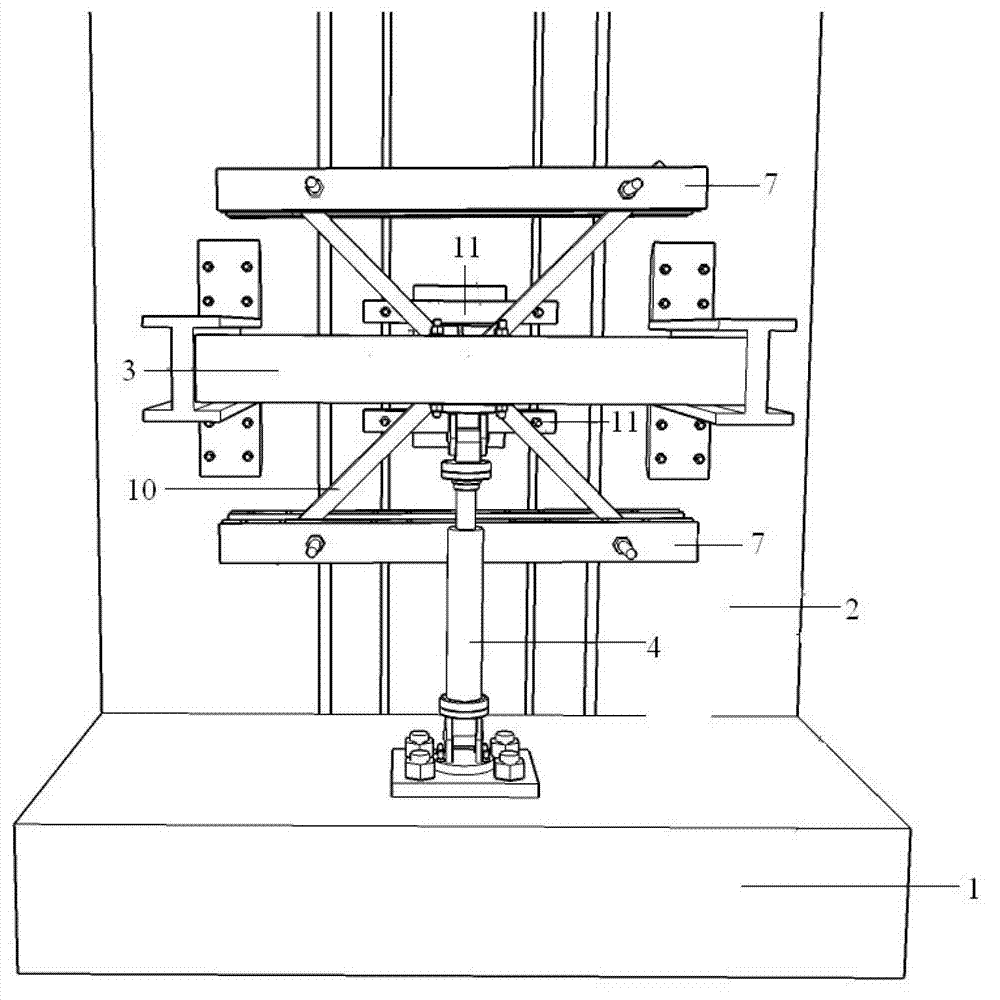

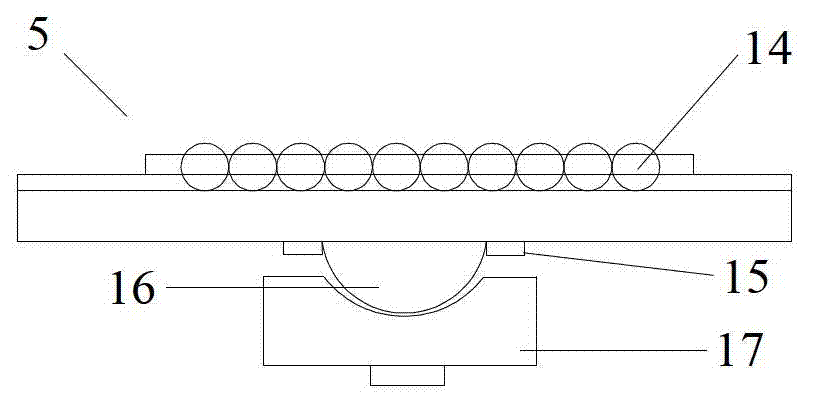

[0024] The special-shaped column-beam structure including the experimental nodes is placed in the loading device composed of reaction wall 1, floor trough 2, column top reaction steel frame 3, beam end reaction steel frame 7, and electro-hydraulic servo actuator 4 , the column top reaction force steel frame 3 is provided with a roller ball hinge device 5, and the lower part of the roller ball hinge device is provided with a hydraulic jack 9, which is used to apply axial pressure to the column body of the special-shaped column. The reaction force of the jack is det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com