Pipeline, sealing element and pipe connection

A technology for sealing components and pipe connections, applied in the field of pipelines, can solve the problems of leakage, increased assembly costs, and danger to users of toxic media equipment, and achieve the effect of improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

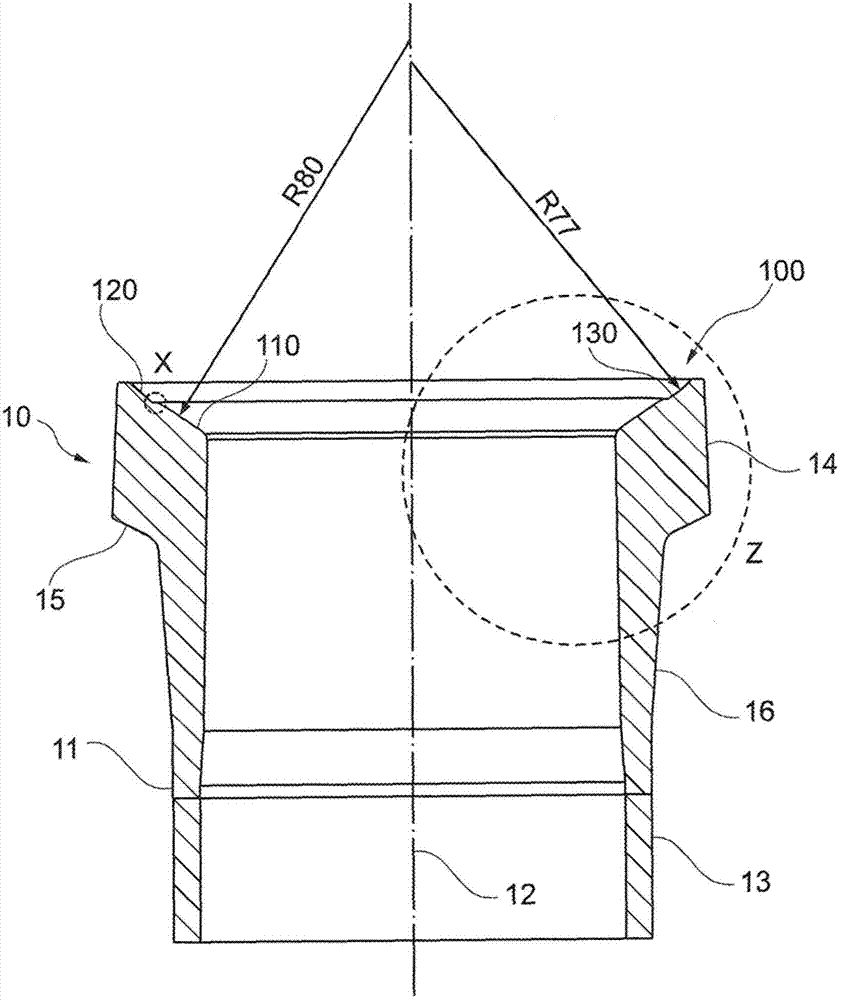

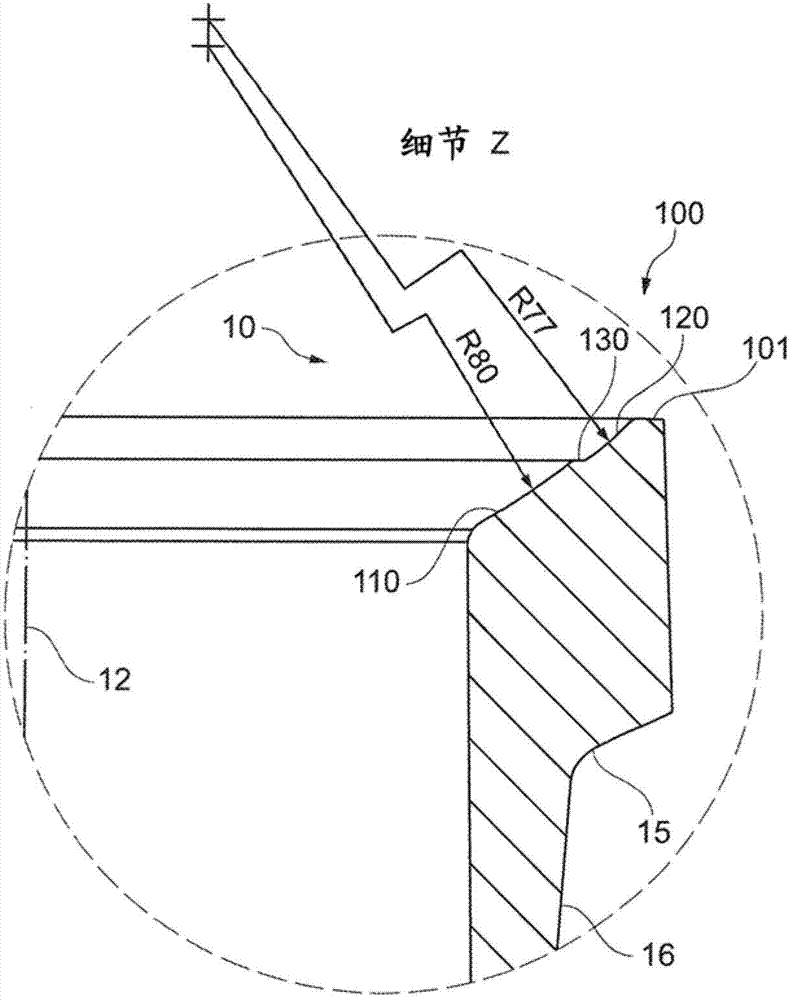

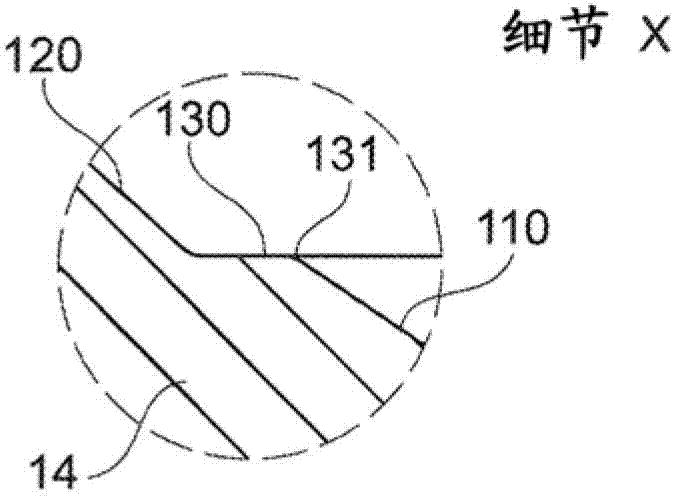

[0024] figure 1 Shows a cross-sectional view of the end of a pipe. in figure 1 The cross-sectional view shown in may refer to the end of a straight or curved pipe or may refer to a T-piece, a Y-piece, a four-branch pipe, a six-branch pipe, or other components known per se for constructing a pipe network Single joint.

[0025] The pipe 10 has a longitudinal section 13 with a substantially constant wall thickness and a parallel outer contour. The longitudinal section 13 is either used to convey the fluid flowing in the interior of the pipe 10 in a straight line or to transfer the figure 1 The end joint shown in is adapted to one of the pipe elements described above.

[0026] The first longitudinal section 13 merges into the support 100 with a second longitudinal section 16. The inner wall and / or outer wall of the second longitudinal section 16 may be inclined outwards by a small amount relative to the first longitudinal section 13. This results in an expansion of the tube cross se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com