Tube cutting device of multi-cutter paper tube making machine

A technology of a tube cutting device and a paper tube machine, which is applied in the mechanical field, can solve the problems of reduced production efficiency, inconvenient operation, and no setting, etc., and achieves the effects of reasonable structure design, convenient operation and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

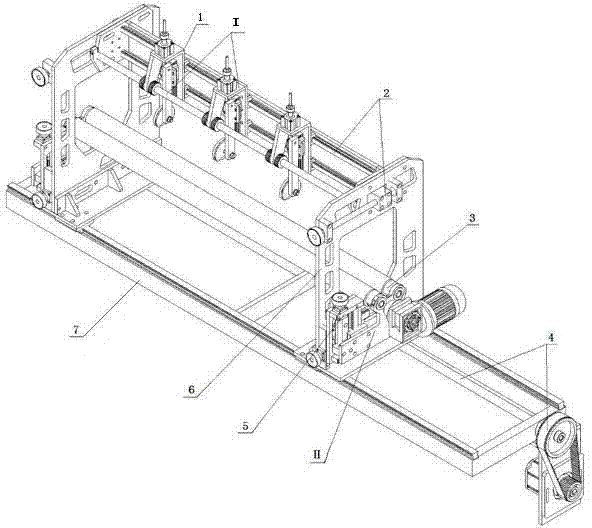

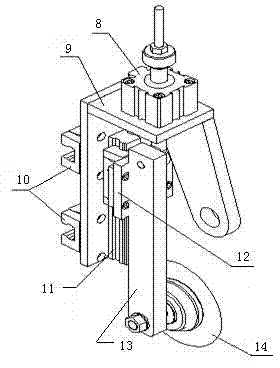

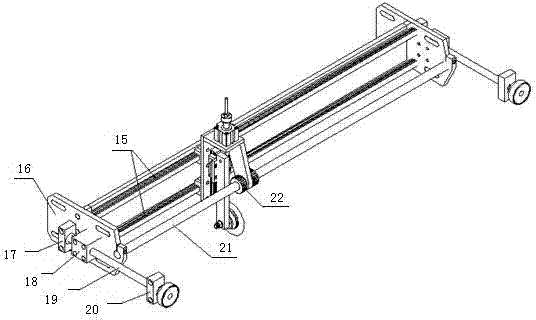

[0024] see Figure 1-Figure 5 In this embodiment, a tube cutting device for a multi-knife paper tube machine includes a cutter device I, an idler device II, a cutting table moving device 4, a vertical plate 6 and a frame 7, and the cutter device I includes a cutter head 1 and a The cutter head adjustment device 2 and the supporting roller device II include a supporting roller rotating mechanism 3 and a supporting roller adjusting mechanism 5 , and the cutting table moving device 4 is connected with the frame 7 .

[0025] In this embodiment, the cutter device I and the roller device II are connected to the iron plate 32 of the cutting table through the vertical plate 6, and the moving device 4 of the cutting table drives the cutter device I and the roller device II to move, and the cutter device I starts to cut the paper tube. , the roller shaft 42 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com