Grinding wheel forming machine

A molding machine and grinding wheel technology, applied in the directions of molding indenters, grinding devices, metal processing equipment, etc., can solve the problems of low production efficiency and long movement time, and achieve the effects of low manufacturing cost, improved production efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

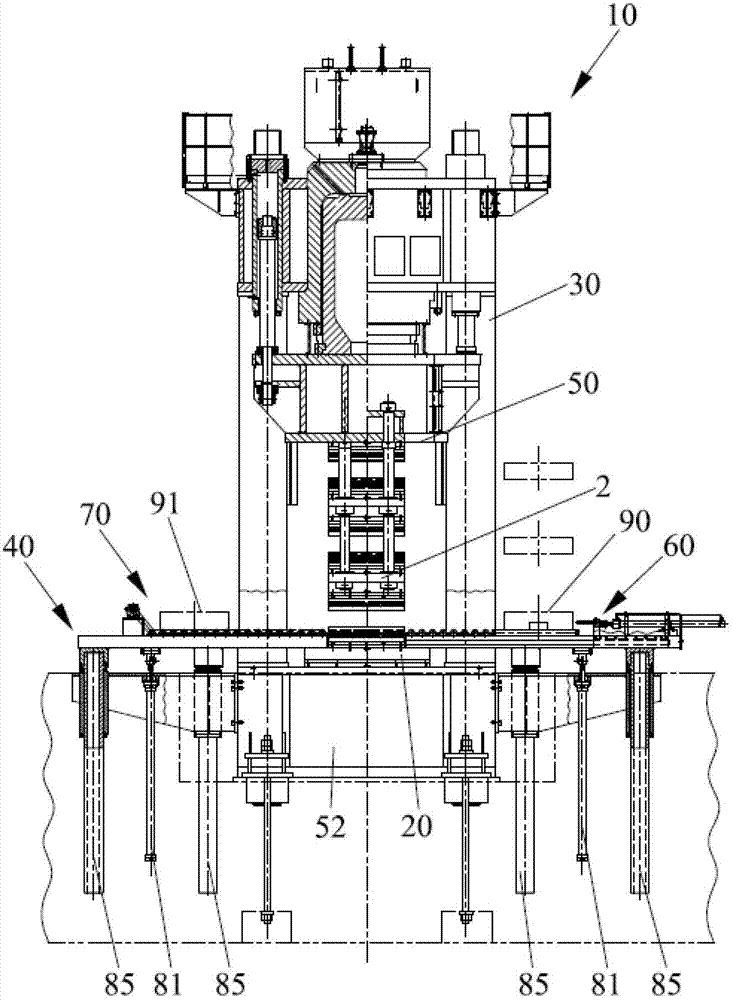

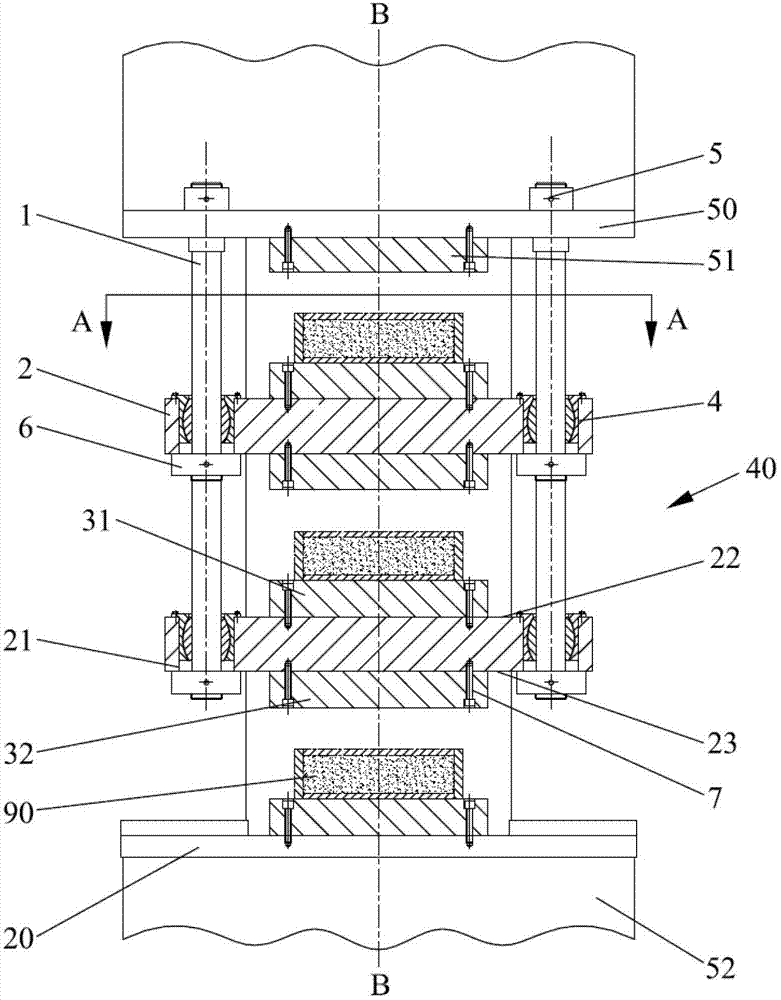

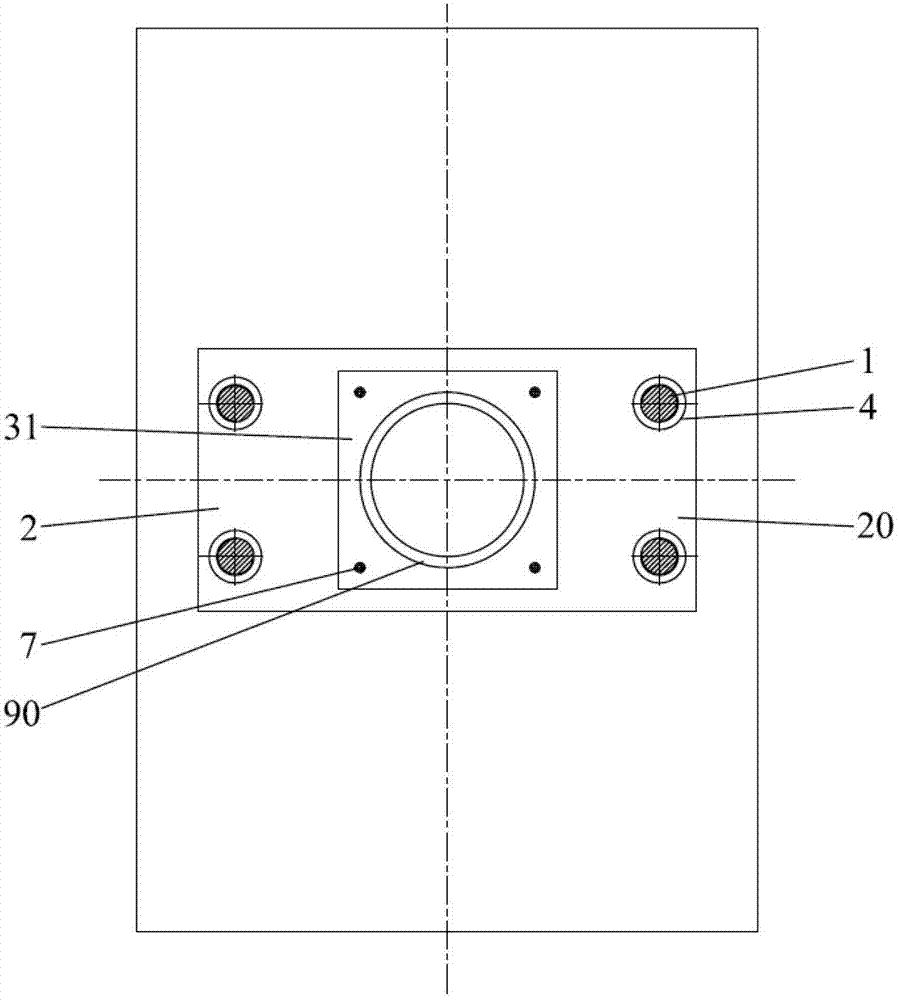

[0025] figure 1 Show a front view of a grinding wheel forming machine of the present invention, the grinding wheel forming machine 10 includes a frame 30 and a multi-layer mold assembly 40 arranged in the middle of the frame 30, the frame 30 includes a movable beam 50 with an upper pressing head 51 And be provided with the base 52 of workbench 20. The workbench 20 supports a grinding wheel mold 90 to be pressed by an upper backing plate, and the multilayer mold assembly 40 is also respectively provided with a grinding wheel mold 90 to be pressed, and preferably each supported on the workbench 20 and the multilayer mold assembly 40 A die is aligned along the vertical axis B of the grinding wheel former. In addition, the grinding wheel mold 90 to be pressed according to the present invention includes a grinding wheel mold main body and raw materials for making a grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com