Energy-saving reversed-opening type flap valve

A door seat and shaft technology, applied in the valve details, functional valve type, valve's device for absorbing fluid energy, etc., can solve the problem of increased door closing impact force, increased door closing time and instantaneous angular velocity, and large water head loss at the water outlet. and other problems, to achieve the effect of small impact force of closed door, reduction of vibration times, and reduction of water head loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

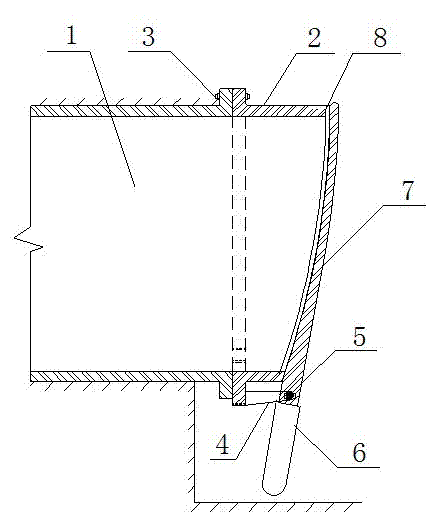

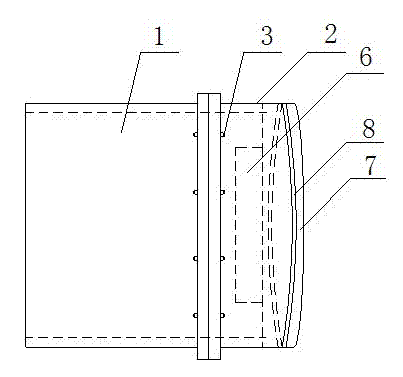

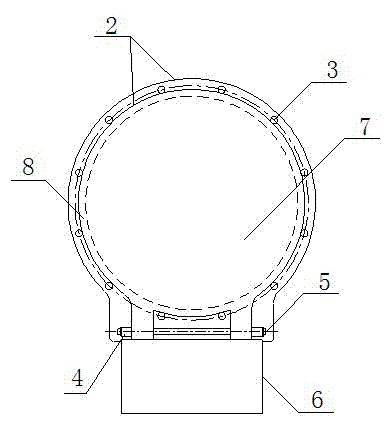

[0013] Below in conjunction with accompanying drawing, the present invention is further described: as Figure 1-3 As shown, a kind of energy-saving reverse-turning flap door includes an outflow pipeline 1, a door seat 2 and a flap door 7. The outflow pipe 1 and the door seat 2 are connected by screws 3, and a hinge is provided under the door seat 2. A shaft support 4, a rotating shaft 5 is arranged inside the hinge shaft supporting 4, and the flap door 7 is in seamless contact with the outer contour of the door seat 2 through the rotating shaft 5, and a counterweight 6 is arranged below the flap door 7.

[0014] The outlet of the door seat 2 is also provided with a buffer water-stop rubber 8 .

[0015] The rotation range of the flap door defined by the hinge shaft support 5 and the outlet pipe 1 is 10°-90°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com