Signal acquisition method of rotation angle of rotating member with V-shaped notch

A technology for signal acquisition and rotating parts, applied in the direction of using electrical devices, measuring devices, instruments, etc., can solve the problem of unable to detect the rotation angle, etc., and achieve the effect of controllable and measurable rotation angle, accurate and reliable signal acquisition, and rotation angle assistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

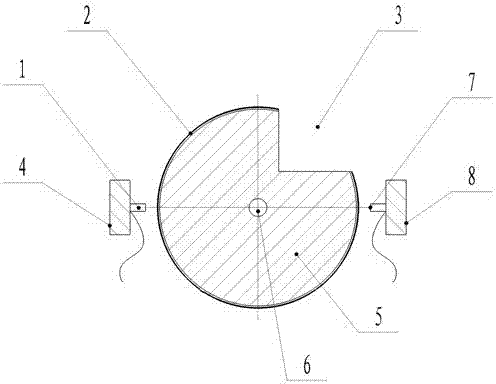

[0031] The invention relates to a signal acquisition method for the rotation angle of a rotary part with a V-shaped notch. In the signal collection method, two symmetrically configured magnetic grid sensors with complementary functions are used to measure the magnetic grid scale pasted on the rotary part with a V-shaped notch. Carry out signal acquisition, thereby solving the rotation angle monitoring of the rotary part with V-shaped notch, the signal acquisition is accurate and reliable, and has a great assisting effect on the computer control of the rotation angle of the rotary part with V-shaped notch, especially for extra-large and precise rotation angles As far as the swivel with V-shaped notch is concerned, its significance is even more profound.

[0032] The present invention can be explained in more detail through the following examples. The present invention is not limited to the following examples. The purpose of disclosing the present invention is to protect all chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com