Method for installing a profiled extruded section

A technology of strips and components, which is applied in the field of installing strips, can solve problems such as consumption and achieve the effect of reducing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

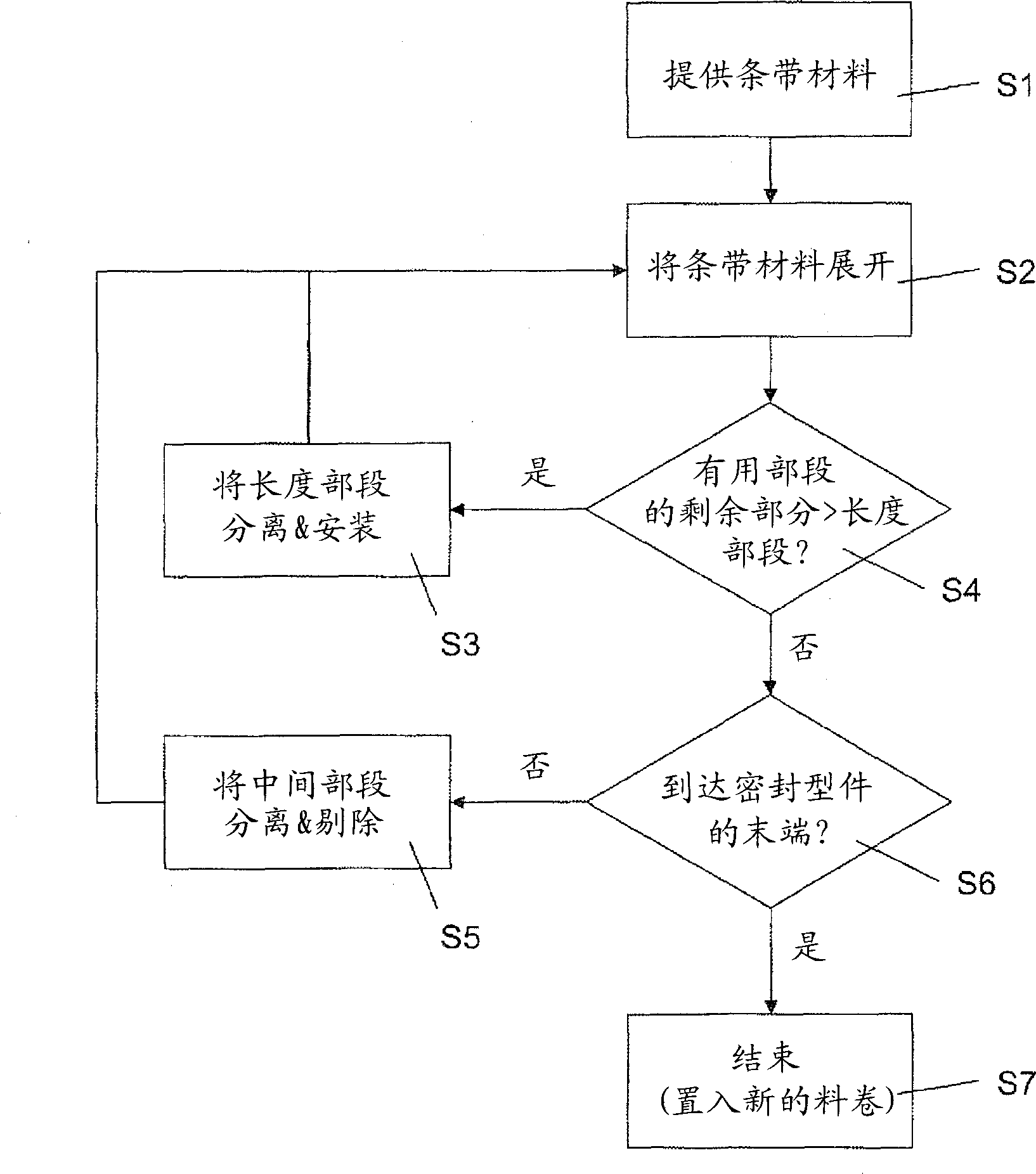

[0026] figure 1 Schematic flow diagram showing a method 1 of installing a sealing profile formed of a strip material on a vehicle component, wherein equidistant length sections of predetermined length from the strip material are periodically separated and rejected as waste .

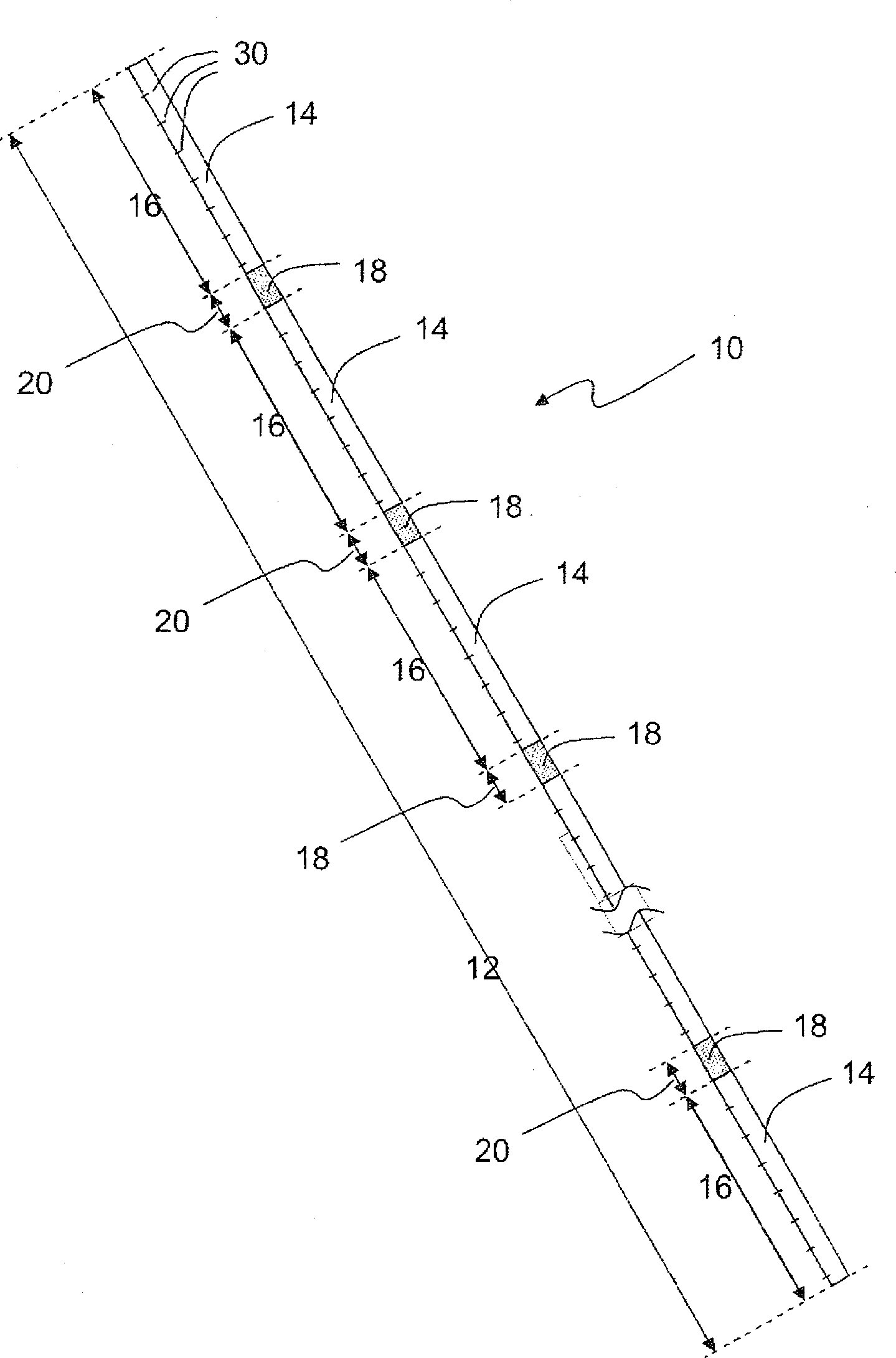

[0027] In a first step S1 , the manufacturer and the supplier provide the vehicle manufacturer, in particular the passenger car manufacturer, with a strip material 10 in the form of a so-called continuous sealing profile.

[0028] An example of a strip material 10 provided by a manufacturer is figure 2shown; it has a total length 12 (for example 1400 m) and a plurality of useful sections 14 with a desired and predetermined state. This predetermined state refers to the predetermined surface properties and geometric shapes that enable the intended use of the strip material present in the useful section 14 as a sealing profile (or as an edge protection profile, etc.). The strip material present in the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com