Preparation method and product of unsterilized vacuum packed boiled salted duck

A technology of vacuum packaging and salted duck, which is applied in the field of food processing, can solve the problems of short shelf life and achieve the effect of delicious taste, avoiding cooking smell and rich aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

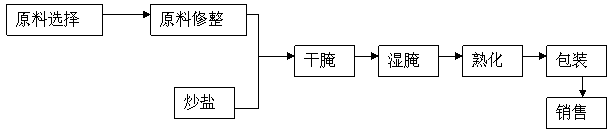

Method used

Image

Examples

Embodiment Construction

[0027] (1) Raw material selection: Cherry Valley duck carcass duck net weight: 1.0-1.2kg / piece.

[0028] (2) Raw material trimming: remove the head, neck, neck lymph, tail fat glands, etc., rinse inside and outside to remove all blood stains, hang the whole duck on a rack, drain the water in the body surface and cavity, and dry-cure it prepare.

[0029] (3) Fried salt: Put 5-10g of star anise and 5-10g of Chinese prickly ash in 1kg of refined salt, pour it into the frying salt machine, and fry for about 20-30min. You can stop the machine to turn out the salt, sieve to remove the slag, after the salt is out, stop the machine and turn it back to add salt to continue frying. After frying and sieving to remove the slag, the fried salt is immediately covered and stored, and the cover is strictly prevented from absorbing moisture, which will affect the quality of the fried salt.

[0030] (4) Dry pickling: Spread the salt evenly on the inside and outside of the duck, put it in a 0-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com