Strain strengthening storage tank

A strain strengthening, storage tank technology, applied in the direction of container, packaging, transportation and packaging, can solve the problem of residual liquid in the storage tank, and achieve the effect of low drainage cost and good drainage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The strain-strengthened storage tank 1 of the present invention will be further described in detail through specific examples below.

[0018] The directions in this example are up and down based on the state of strain-strengthened storage tanks in normal use. The mentioned inner groove head refers to the head without lining ring, and the outer groove head refers to the head with lining ring. head.

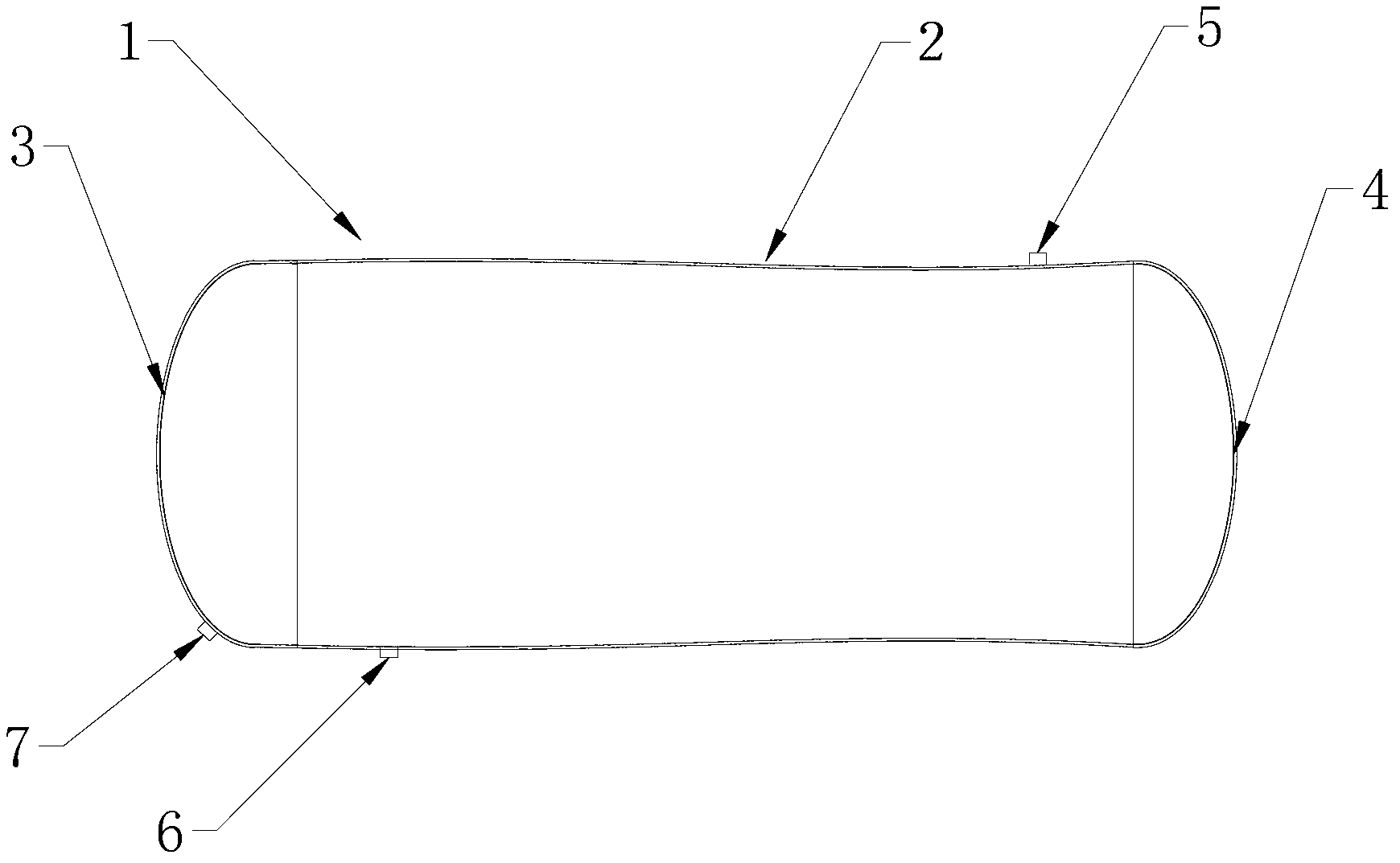

[0019] Such as figure 1 As shown, a strain strengthening storage tank 1, the storage tank 1 includes a cylinder body 2 and a head, the head includes an inner groove head 3 and an outer groove head 4, the upper part of the cylinder body 2 and the lower part are respectively provided with an exhaust port 5 and a first liquid discharge port 6, and the lower part of the inner beveled head 3 is also provided with a second liquid discharge port 7, and the outer beveled head 4 is lifted upwards to form 15 degrees with the ground. °-20°, the second drain port 7 is located at the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com