Three-cavity diaphragm pump comprising main shaft provided with limiting structure

A technology of limiting structure and diaphragm pump, applied in the direction of pumps with flexible working elements, pumps, liquid variable capacity machines, etc., can solve the problems of easy breakage of cylindrical pins, troublesome maintenance, inconvenient production, etc., and improve the connection reliability. , to avoid the effect of large pulling effect and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

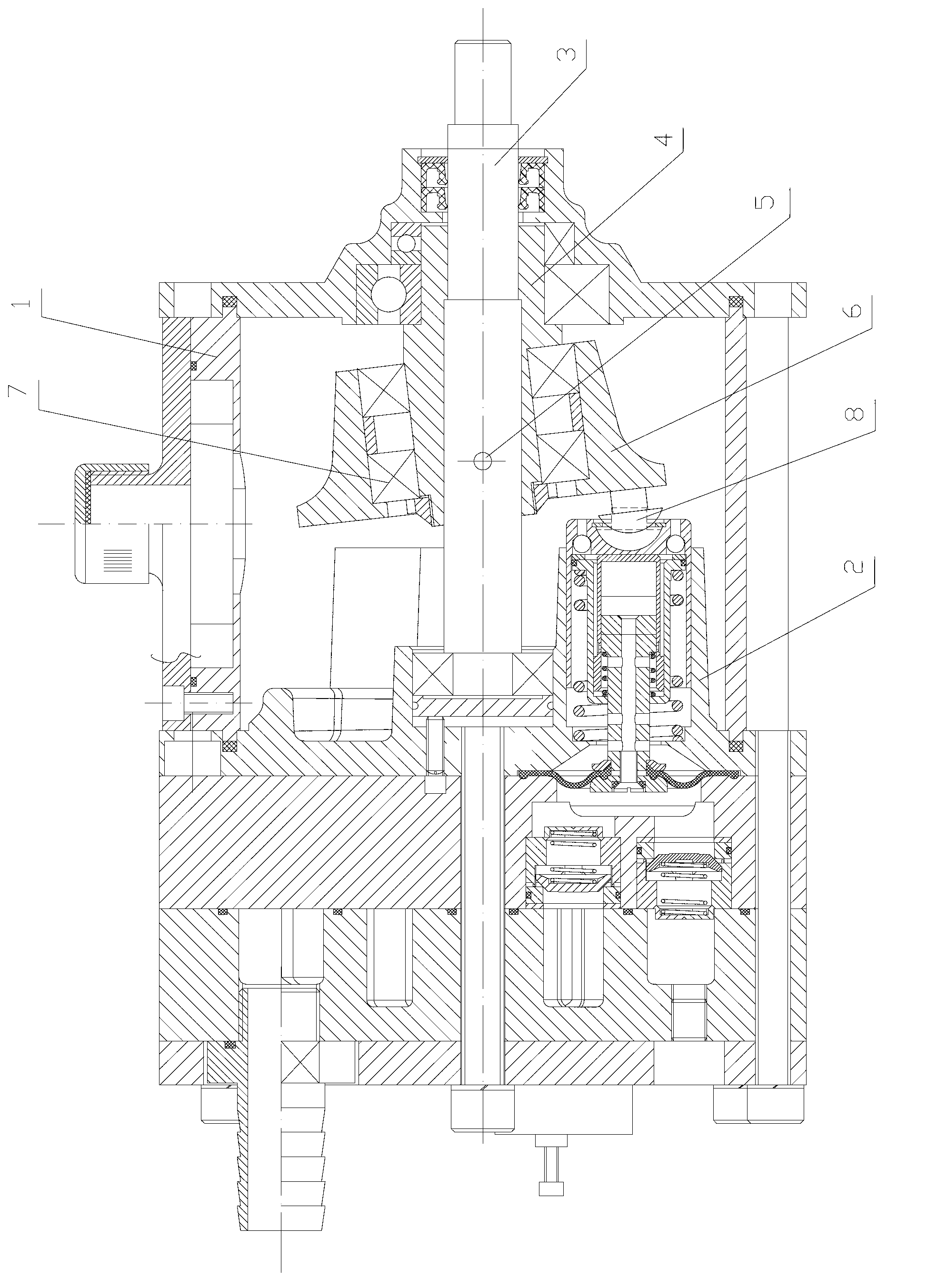

[0014] see figure 1 , the present invention provides a three-chamber diaphragm pump with a limiting structure for the main shaft, which includes a housing 1, a pump body 2 connected to the housing 1, and a main shaft 3 connected to the motor; the main shaft 3 and the eccentric sleeve 4 pass through a cylindrical pin 5 is fixedly connected, the wheel disc 6 is fixedly connected with the eccentric sleeve 4 through the bearing 7; at the same time, the wheel disc 6 is connected with the spherical shaft 8 arranged on the pump body 2, and the main shaft 3 has a device that limits itself along the axial direction. A limit structure for movement outside the housing 1.

[0015] In this embodiment, the position-limiting structure is a stepped structure, the main shaft 3 is a different-diameter structure, and is installed in the eccentric sleeve 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com