Engine laminate restrictor test board

A laminate restrictor and test bench technology, which is applied in the testing of machine/structural components, testing of mechanical components, instruments, etc., can solve the problem of incomplete on-site testing, affecting engine troubleshooting and normal use, wasting time and financial resources and other issues to achieve the effect of small footprint, strong versatility and scalability, and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

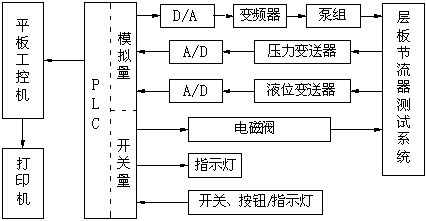

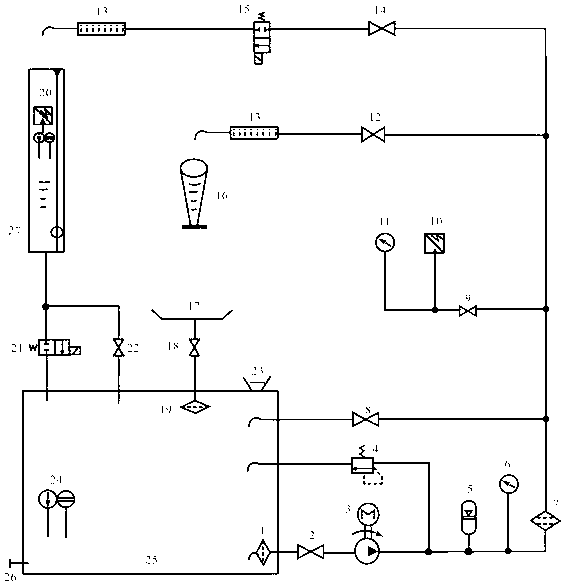

[0022] The present invention will be further described below in conjunction with the accompanying drawings: a test bench for engine floor throttle, which is equipped with an automatic measurement and control system and a floor throttle test system in the body of the test bench, wherein the automatic measurement and control system includes a flat industrial computer, The frequency converter and the PLC communicating with the flat-panel industrial computer, the frequency converter is electrically connected to the PLC through the D / A conversion module; the fuel tank 25 and the explosion-proof fuel pump group 3 connected to the fuel tank 25 are installed in the body of the lower part of the test bench, and the PLC is connected through the frequency conversion The device is electrically connected to the frequency conversion motor of the explosion-proof fuel pump group 3, and the laminate restrictor test system is connected to the flame-proof fuel pump group 3 through the oil pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com