Comprehensive integral testing equipment for density and thermal shock damage of ceramic

A test equipment and compactness technology, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problem that ceramic products cannot be tested for compactness and thermal shock damage at the same time, and achieve the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

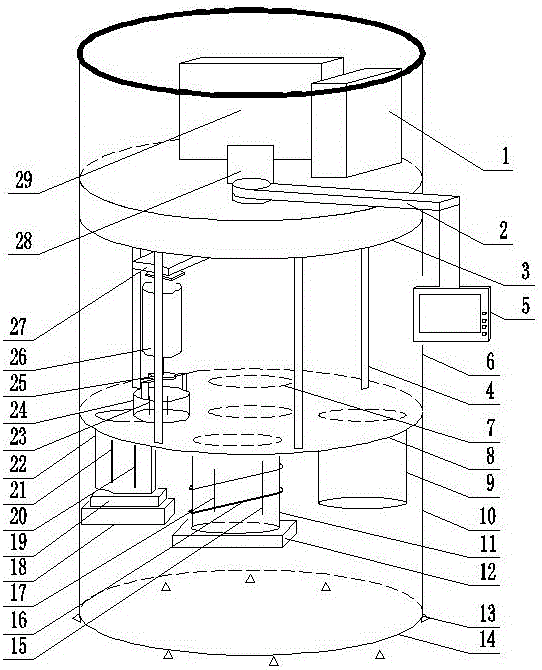

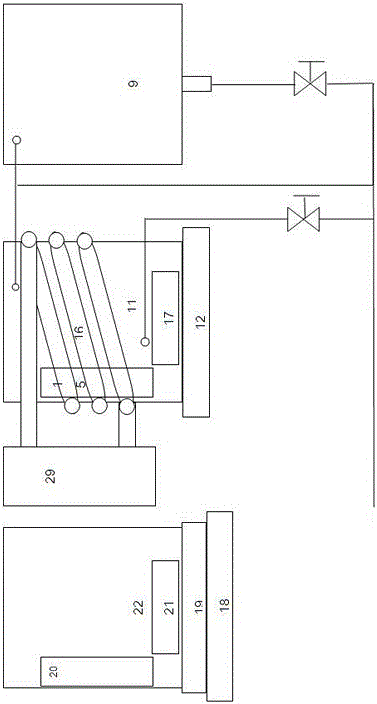

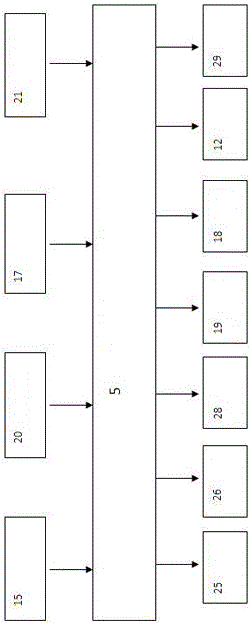

[0030] The board invention will be further described below in conjunction with the accompanying drawings.

[0031] The following examples are used to illustrate the present invention, but cannot be used to limit the protection scope of the present invention. The conditions in the examples can be further adjusted according to specific conditions, and the unspecified conditions are the conditions in the routine experiment.

[0032] This embodiment discloses an integrated test equipment for ceramic compactness and thermal shock damage. The equipment includes a heating system, a refrigeration system, a control system, a mechanical execution system, a work surface and a support. Select the thermal shock damage mode or the water absorption rate mode by operating the industrial computer control program, and replace the corresponding heating cylinder and solution for implementation.

[0033] See the structure and principle of the equipment Figure 1-3 ,

[0034] see figure 1 , The frame inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com