Method for detecting inoxidizability of lubricating oil

A technology of anti-oxidation and detection method, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of cumbersome detection steps, expensive detection instruments, etc., and achieve the effect of intuitive results, easy to determine, and conducive to popularization and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

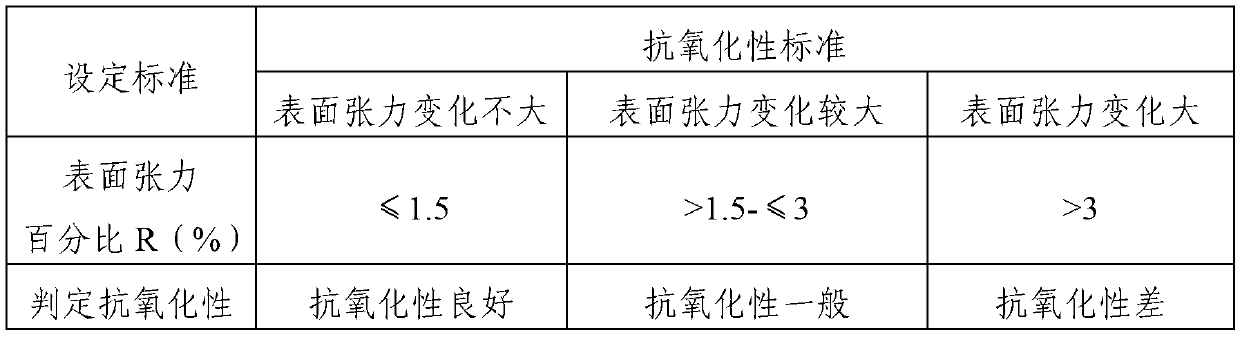

Image

Examples

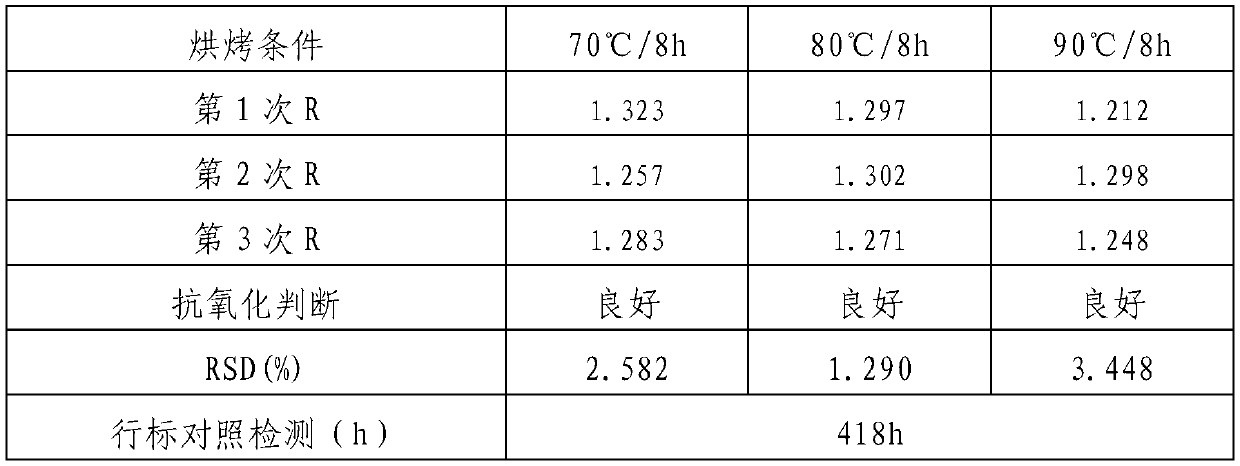

Embodiment 1

[0020] Take 200g of 1# lubricating oil, and use the following method to carry out the oxidation resistance test:

[0021] (1) Surface tension measurement before baking: measure the surface tension value N1 of 1# lubricating oil;

[0022] (2) Baking sample: put 1# lubricating oil in an oven and bake at a constant temperature of 70°C for 6 hours;

[0023] (3) Surface tension measurement after baking: measure the surface tension value N2 of 1# lubricating oil after baking;

[0024] (4) Result analysis: Calculate the surface tension change rate R=(N1-N2) / N1×100% and relative standard deviation RSD of 1# lubricating oil.

[0025] Adjust the baking conditions, bake at a constant temperature in an oven at 80°C for 8 hours, and repeat the above steps (1)-(4).

[0026] Adjust the baking conditions, bake in a 90°C oven at a constant temperature for 12 hours, and repeat the above steps (1)-(4).

[0027] At the same time, the industry standard SH / T 0193-2008 Lubricating Oil Oxidation S...

Embodiment 2

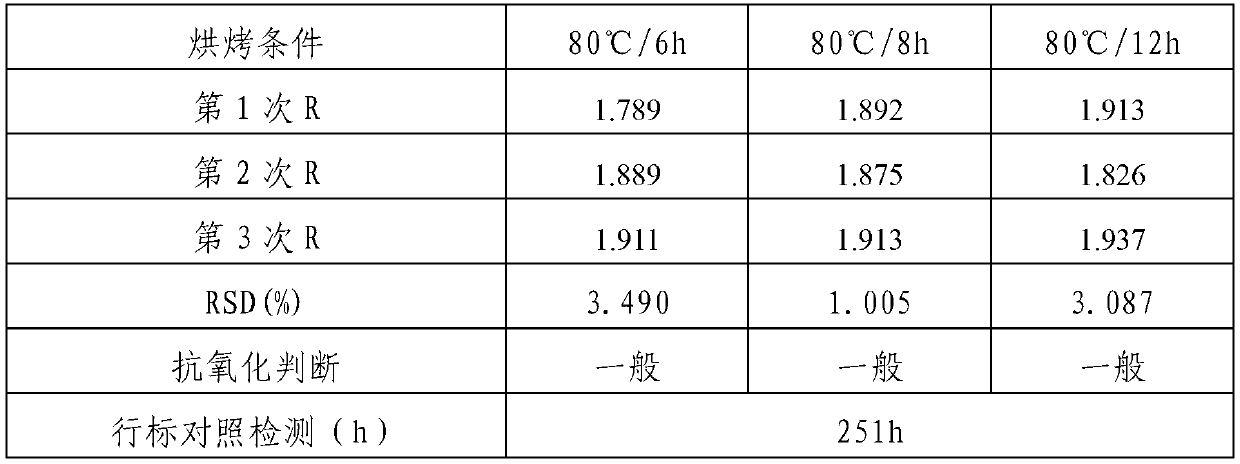

[0032] take 2 # Lubricating oil 300g, detection method is the same as embodiment 1, and surface tension test result and judgment are shown in Table 3. At the same time, industry standards were used to conduct a comparative verification of its antioxidant activity, and the results are also shown in Table 3.

[0033] Table 3 Test results of oxidation resistance of 2# lubricating oil

[0034]

[0035] It can be seen from Table 3 that the anti-oxidation time of the industry standard detection reaches 251h, indicating that 2 # Lubricating oil has general oxidation resistance and relatively stable properties. This test method shows that 2 # The results of lubricating oil oxidation resistance are consistent with it.

Embodiment 3

[0037] take 3 # Lubricating oil 400g, detection method is the same as embodiment 1, and surface tension test result and judgment are shown in Table 4. At the same time, industry standards were used to conduct a comparative verification of its antioxidant activity, and the results are also shown in Table 4.

[0038] Table 4 Test results of oxidation resistance of 3# lubricating oil

[0039]

[0040] It can be seen from Table 4 that the line mark detection 3 # The anti-oxidation time of lubricating oil reaches 137h, which means 3 # Lubricating oil has poor oxidation resistance and unstable properties. This test method shows 3 # The results of lubricating oil oxidation resistance are consistent with it.

[0041] Table 4 Test results of base oil oxidation resistance

[0042]

[0043]

[0044] It can be seen from Table 4 that the base oil anti-oxidation time of the industry standard test reaches 283 hours, which means that the base oil has general anti-oxidation prope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com