Integral suspension type in-mold tapping device

A suspended and integrated technology, applied in the direction of thread cutting device, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient feeding of automatic feeding mechanism, affecting the normal operation of tapping mechanism, and small feeding space, so as to achieve the convenience of automatic production and processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

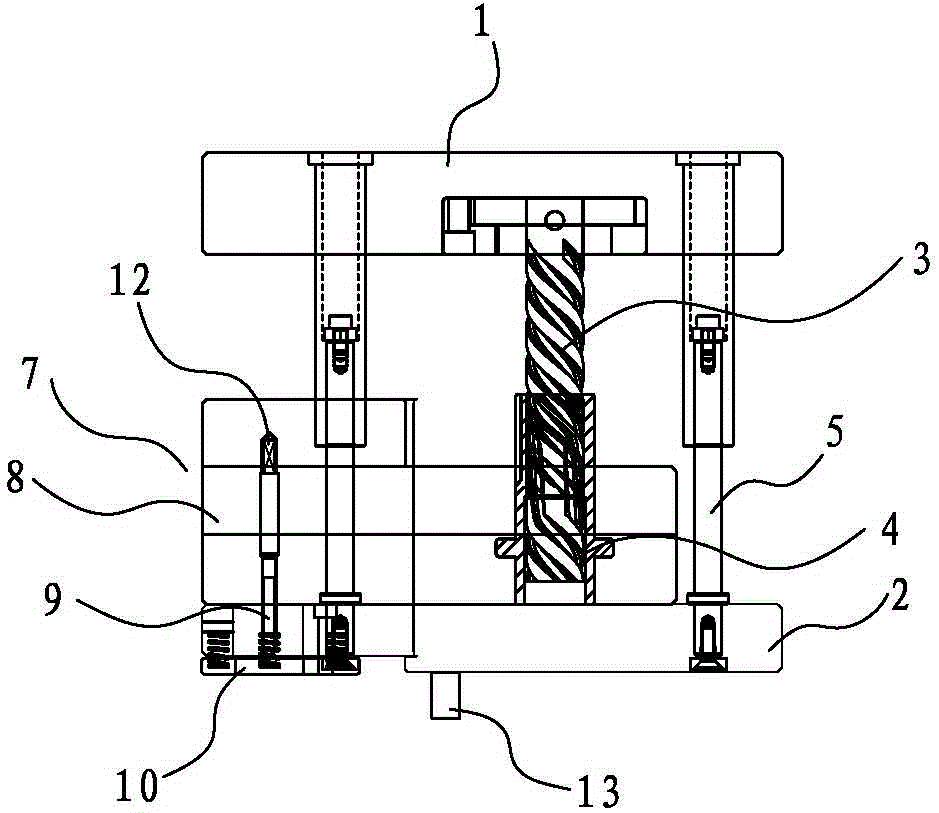

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

[0044] In the figure, a transmission screw rod 3 is also fixedly installed on the upper backing plate 1 .

[0045] A plurality of nitrogen springs 5 are connected between the upper backing plate 1 and the lower backing plate 2 .

[0046] A plurality of positioning guide posts 13 are arranged on the lower surface of the lower backing plate 2 .

[0047] A transmission cup 4 corresponding to the transmission screw 3 is also rotatably installed on the lower backing plate 2 .

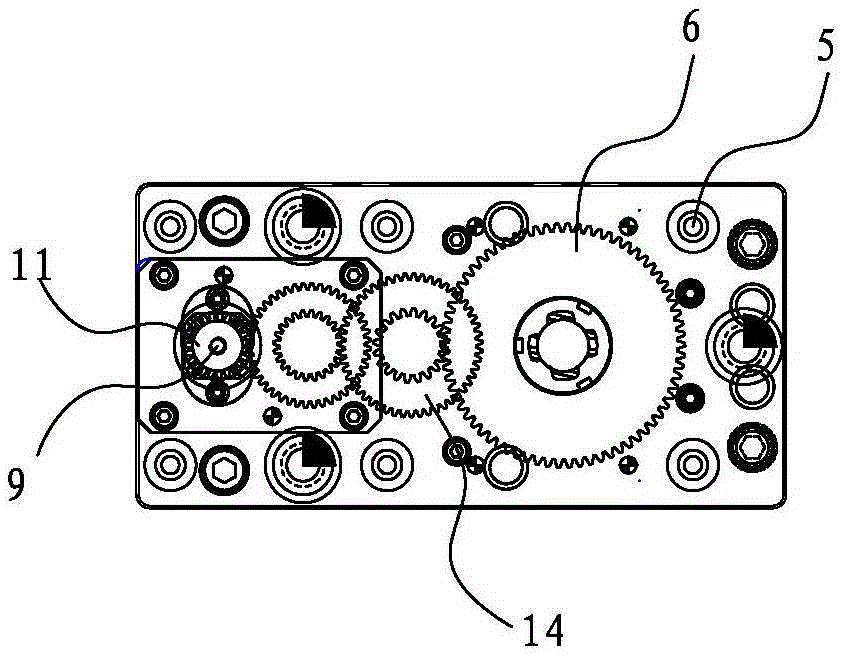

[0048] The driving gear 6 is sleeved on the transmission cup 4 .

[0049] The tapping mechanism 7 is fixedly installed on the lower backing plate 2 .

[0050] The tapping mechanism 7 includes a housing 8 , a screw tap 9 , a floating plate 10 , a driven gear 11 and a screw mandrel 12 .

[0051] The driven gear 11 is fixedly installed in the housing 8 and can freely rotate alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com