Driving module, camera module and electronic equipment

A drive module and drive circuit technology, which is applied in optics, instruments, cameras, etc., can solve the problems of high requirements for anti-shake motors, easy to generate jitter, complex structure and process, etc., achieve good optical anti-shake performance, increase travel space, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

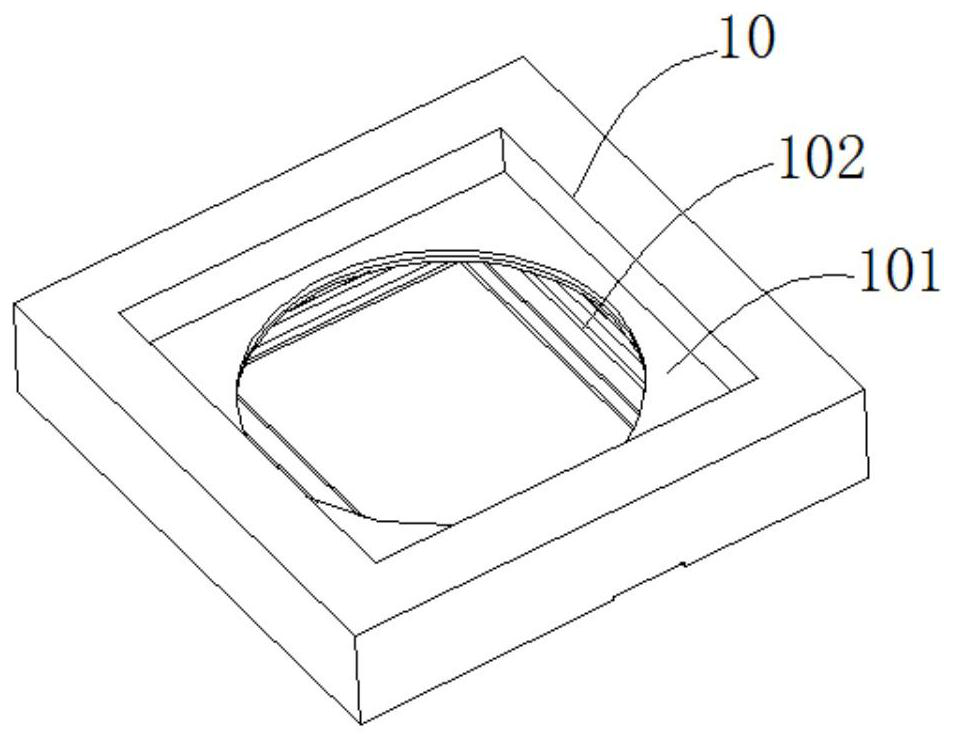

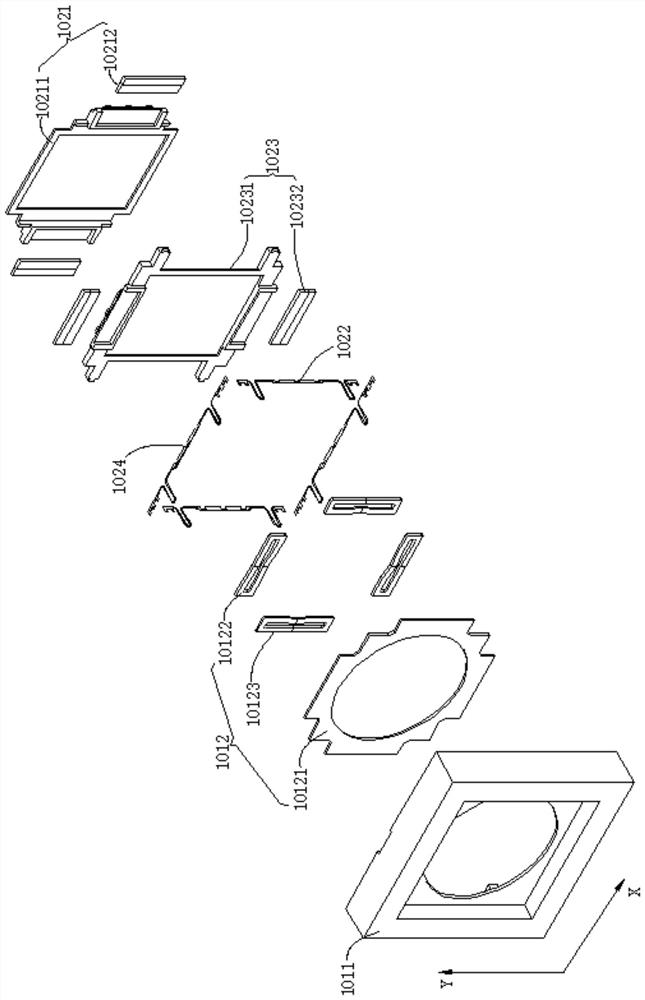

[0039] see figure 1 and figure 2 , figure 1 is a structural schematic diagram of the drive module of the present invention, figure 2 is an exploded view of the drive module of the present invention. An embodiment of the present invention provides a driving module 10, the driving module 10 can be equipped with various focus motors, so that the focus motor has optical anti-shake performance, and at the same time, after the focus motor is equipped, the optical axis accuracy of the AA process of the module can be improved . Specifically, the drive module 10 includes a stator component 101 and a mover assembly 102 .

[0040] In an embodiment of the present invention, the stator component 101 includes a casing 1011 and a driving circuit 1012. In this embodiment, the shape of the casing 1011 may be a square, or other shapes such as a circle or a hexagon. In order to facilitate the mounting of the focus motor, a mounting slot is generally provided in the middle of the housing 1...

Embodiment 2

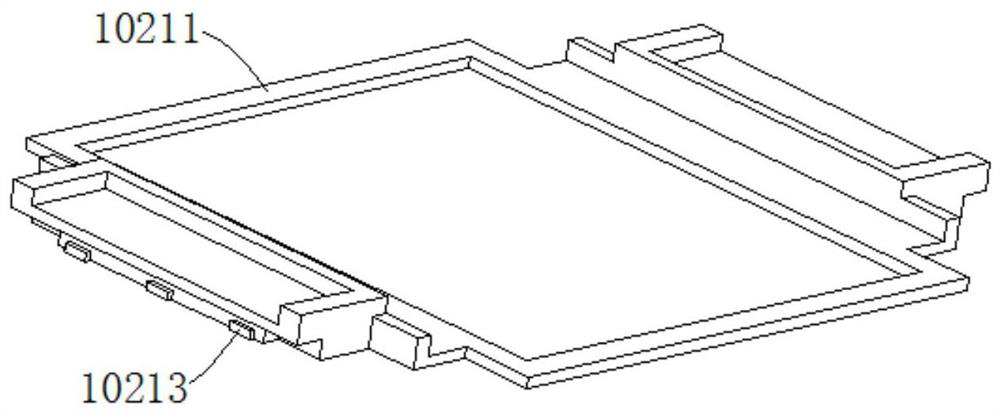

[0065] see Figure 7 , Figure 7 It is a structural schematic diagram of the camera module of the present invention. An embodiment of the present invention provides a camera module, which includes the above driving module 10 . Specifically, the camera module 20 includes a focus motor 30 and a lens assembly 40. The lens assembly 40 includes an image sensor. The focus motor 30 is connected to the lens assembly 40. When specifically connected, the lens assembly 40 is connected to the focus motor 30 On the carrier, the image sensor is connected to the X-direction bracket 10211 of the driving module 10. When the coil of the focus motor 30 is energized, the carrier can move along the optical axis direction of the lens assembly 40, so that the lens assembly 40 can be driven to realize automatic focusing; At the same time, the driving module 10 can perform shake compensation on the image sensor.

Embodiment 3

[0067] see Figure 8 , Figure 8 It is a structural schematic diagram of the electronic equipment of the present invention. An embodiment of the present invention provides an electronic device, which includes the aforementioned camera module 20 . Specifically, the electronic device 50 can be a mobile phone, a tablet computer, a phone watch, a security camera, a vehicle camera, etc., and the electronic device includes a camera module 20 and a casing 501 , and the camera module 20 is arranged on the casing 501 .

[0068] The above-mentioned drive module, camera module and electronic equipment are equipped with various focus motors on the drive module, and use the interaction between the stator component and the mover component to make the focus motor have optical anti-shake performance. Moreover, the present invention uses the X-direction shrapnel and the Y-direction shrapnel to replace the previous suspension wires, which increases the travel space and makes the optical anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com