Low Latitude Dish Stirling Solar Power Plant

A technology of a power generation device and a Stirling engine, which is applied in the field of Stirling solar power generation systems, can solve the problems of less than 90°, unable to control the deviation of the light spot, etc., and achieves the effects of high radiation intensity and long sunlight time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

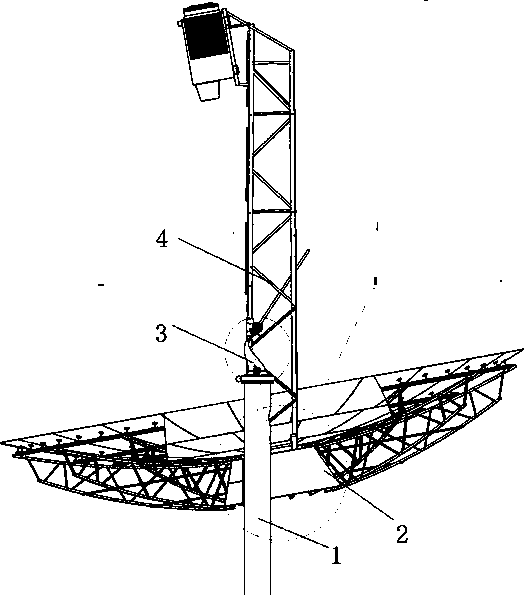

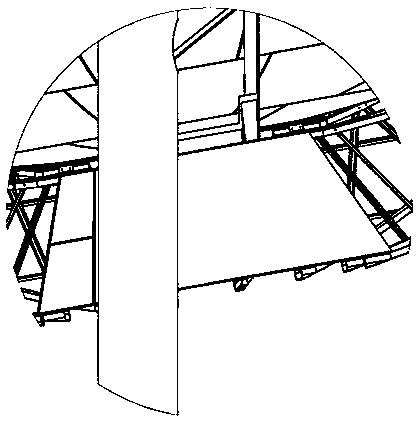

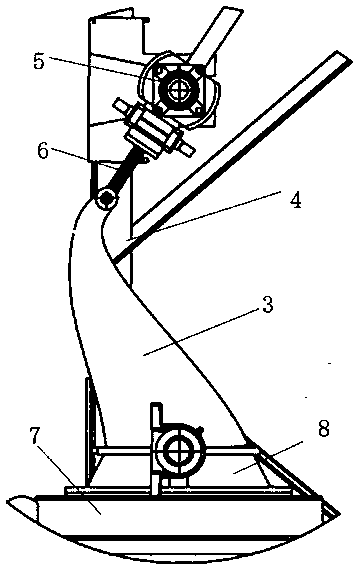

[0017] As shown in the figure, compared with the prior art, the specific modifications in the design of the mechanical structure are as follows: 1. The screw support arm 4 is changed from an upright structure to an olecranon shape. 2. The disc support flange 2 is changed from the same upper and lower sides to a trumpet shape with a small top and a big bottom.

[0018] The Tirling engine is installed on the dish concentrator through the Stirling arm 4. The dish surface support flange 2 of the dish concentrator is in the shape of a trumpet with a small upper part and a larger lower part, and is set on the column 1. The upper end of the column 1 is installed The rotating flange 7 is equipped with a mounting base 8 on the upper end of the rotating flange 7, and the Stirling arm 4 is hinged on the center of the mounting base 8 above the rotating flange 7. 3 is an olecranon shape, and its upper end deviates in the opposite direction to the opening of the U-shaped groove of the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com