Cooling system with coolant circulation duct

A coolant and pipeline technology, applied in the field of injection molding, can solve problems such as the inability to guarantee the expansion volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

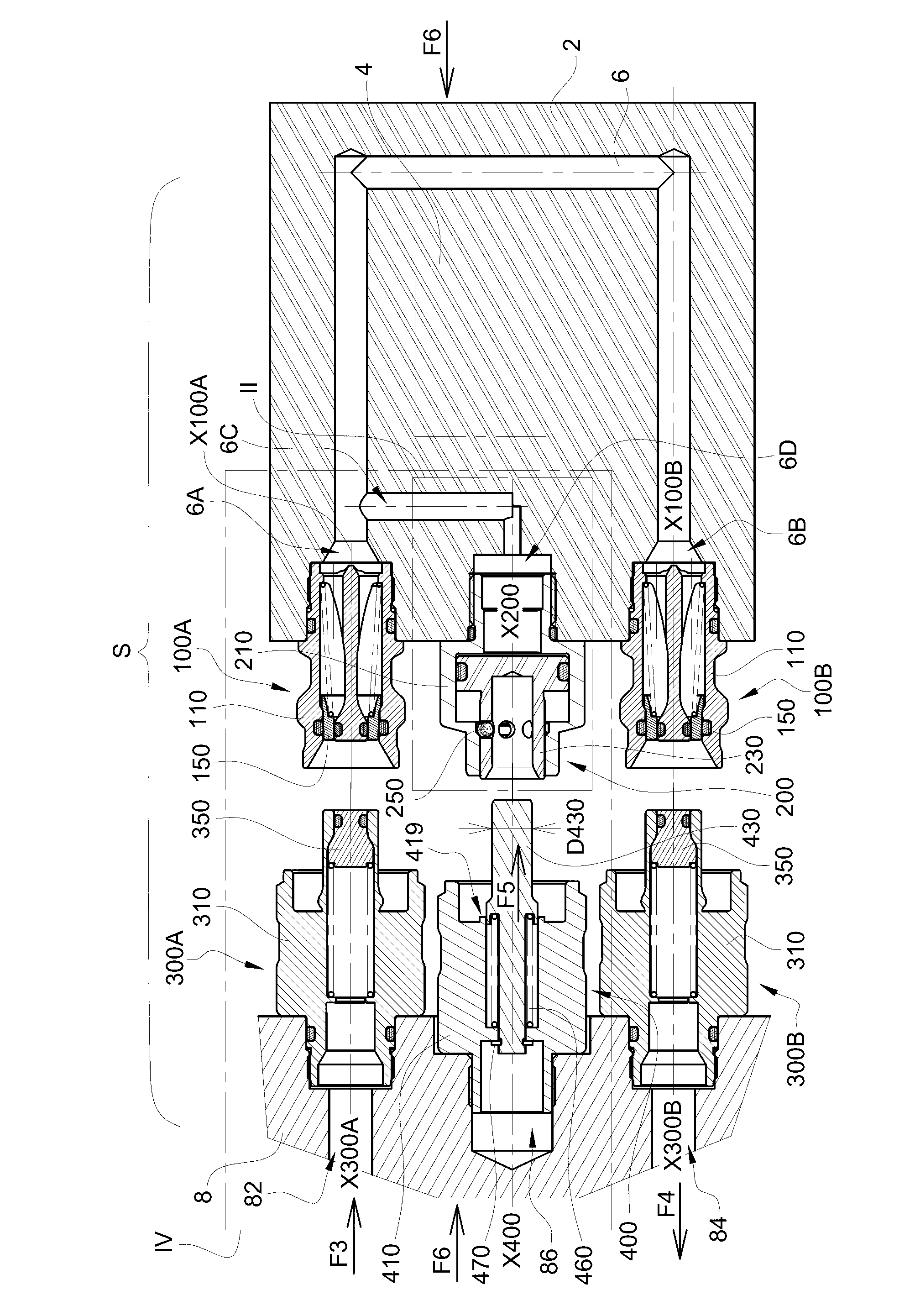

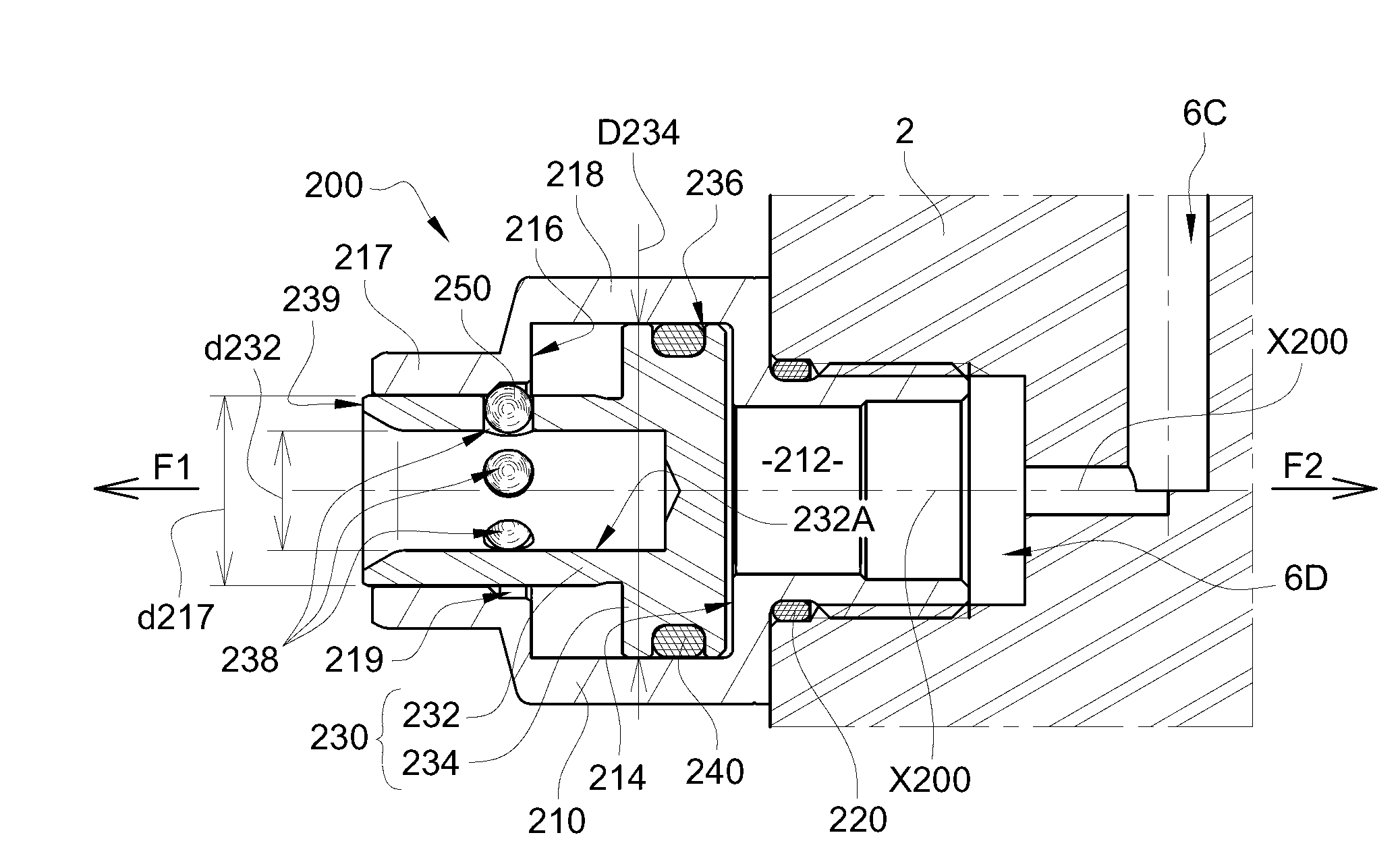

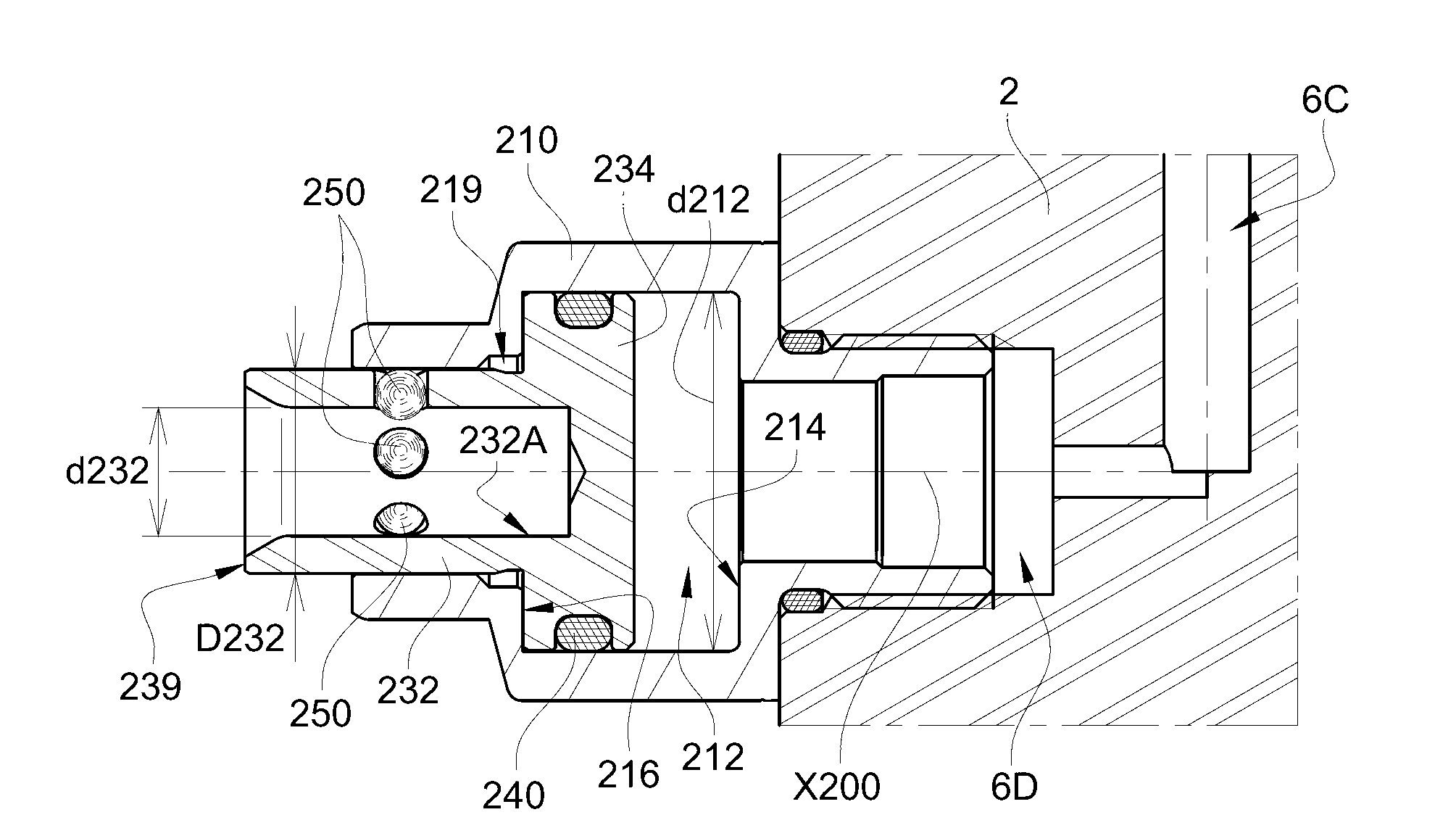

[0029] exist figure 1 In , a heat exchange plate 2 is used to cool electronic devices 4 of the Insulated Gate Bipolar Transistor (IGBT) type or any other components that become hot during operation. Circulation pipes 6 for a coolant such as water or oil are formed in the plate 2 and extend between a first end 6A and a second end 6B, each end being fitted with a connector element 100A or 100B respectively .

[0030] These connector elements 100A and 100B are identical and each comprise a body 110 screwed into a corresponding threaded hole of the corresponding board 2 and inserting a seal 120 . Each body 110 is hollow and defines a central bore 130 within which a push-piece 140 is stationary relative to said body 110 . Said central hole 130 constitutes the internal conduit of the connector element 100A. A closure element or valve 150 is mounted in the central bore 130 and is acted upon by an elastic return spring 160 for springing the closure element 150 back onto the seat 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com