Paint can extender

a paint can and extender technology, applied in the field of containers, can solve the problems of changing the thermal properties of paint, overflowing paint, and the small opening of the paint can that cannot provide a snug snap-fit connection, so as to reduce space and material, and achieve efficient configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

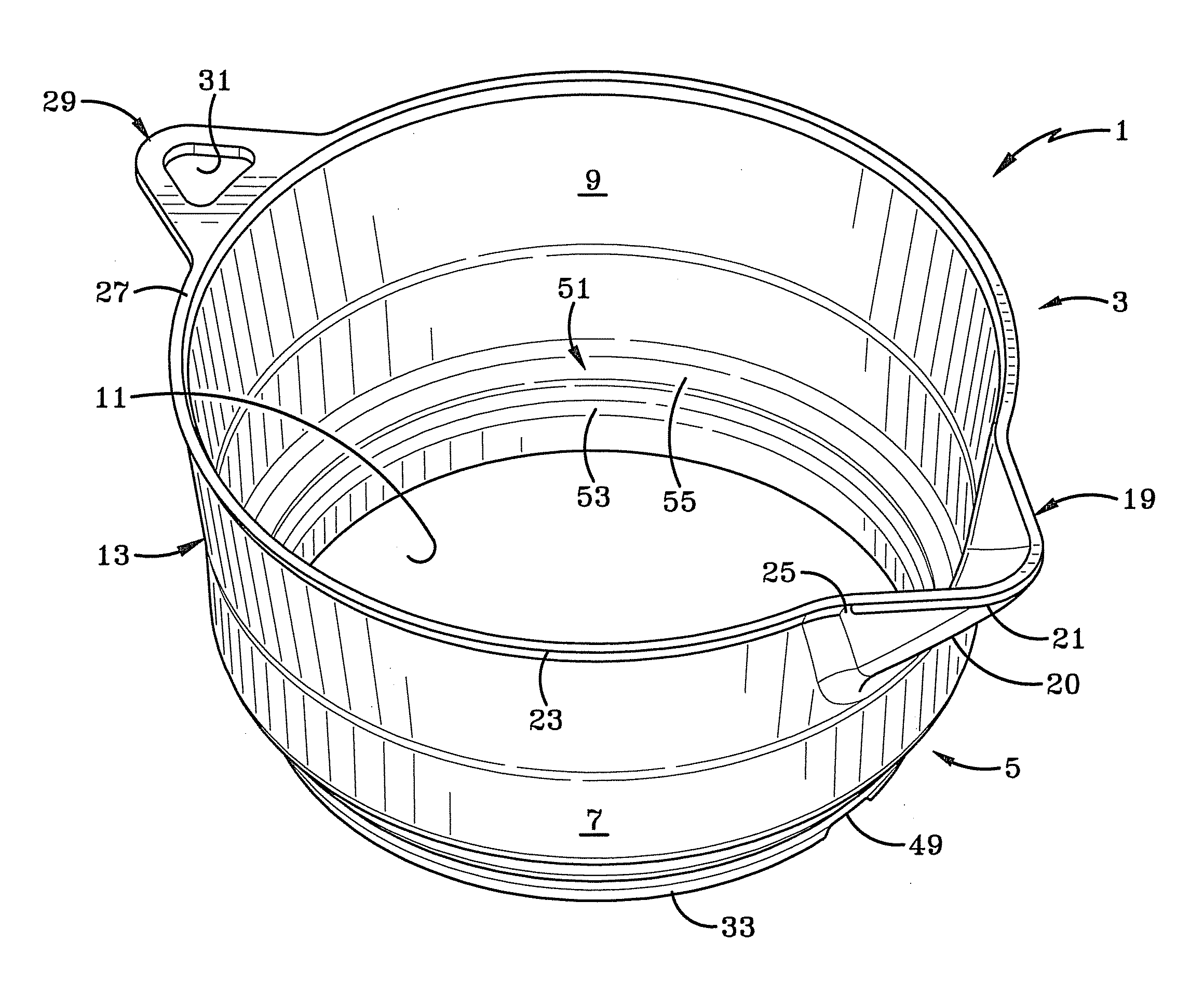

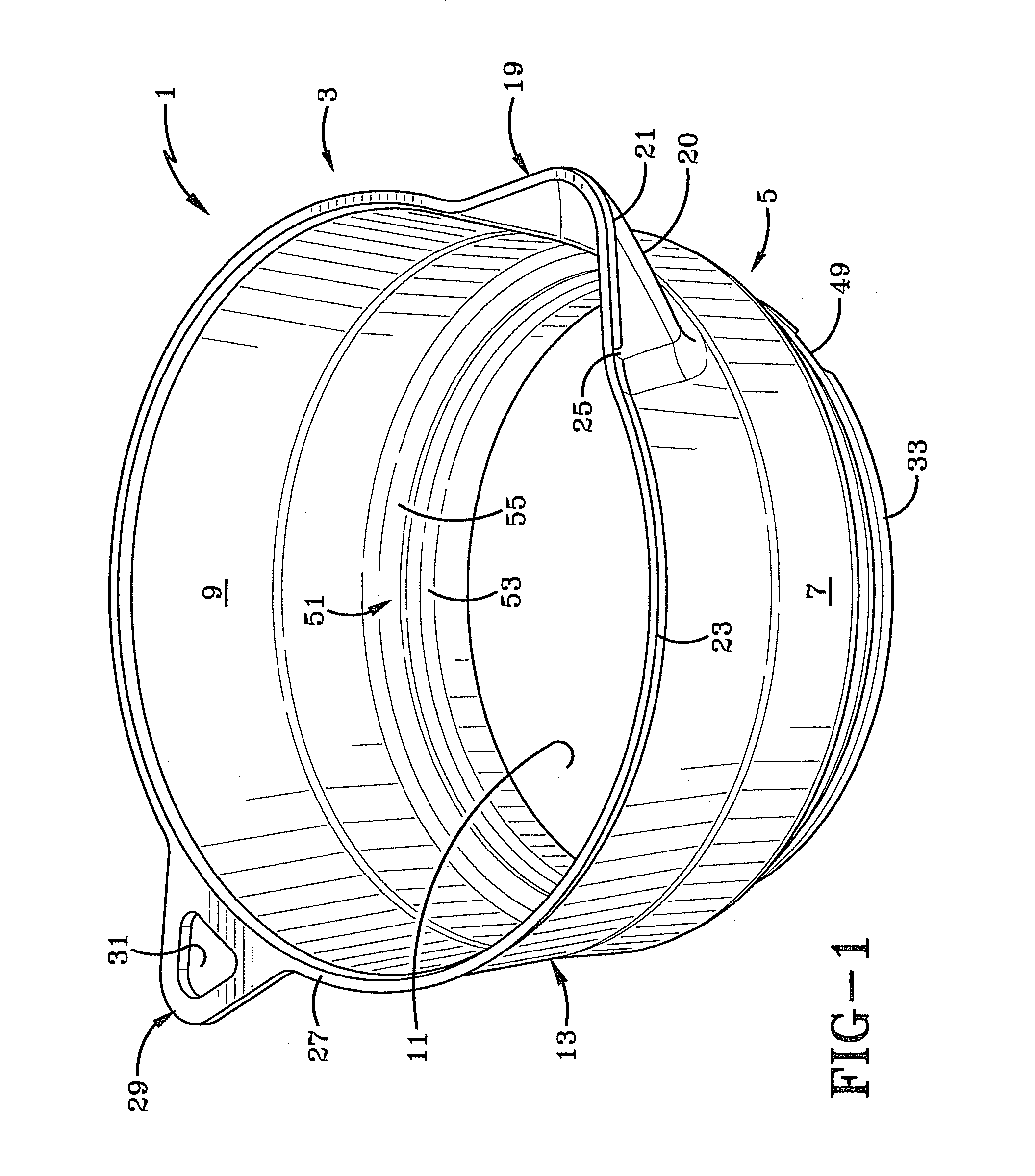

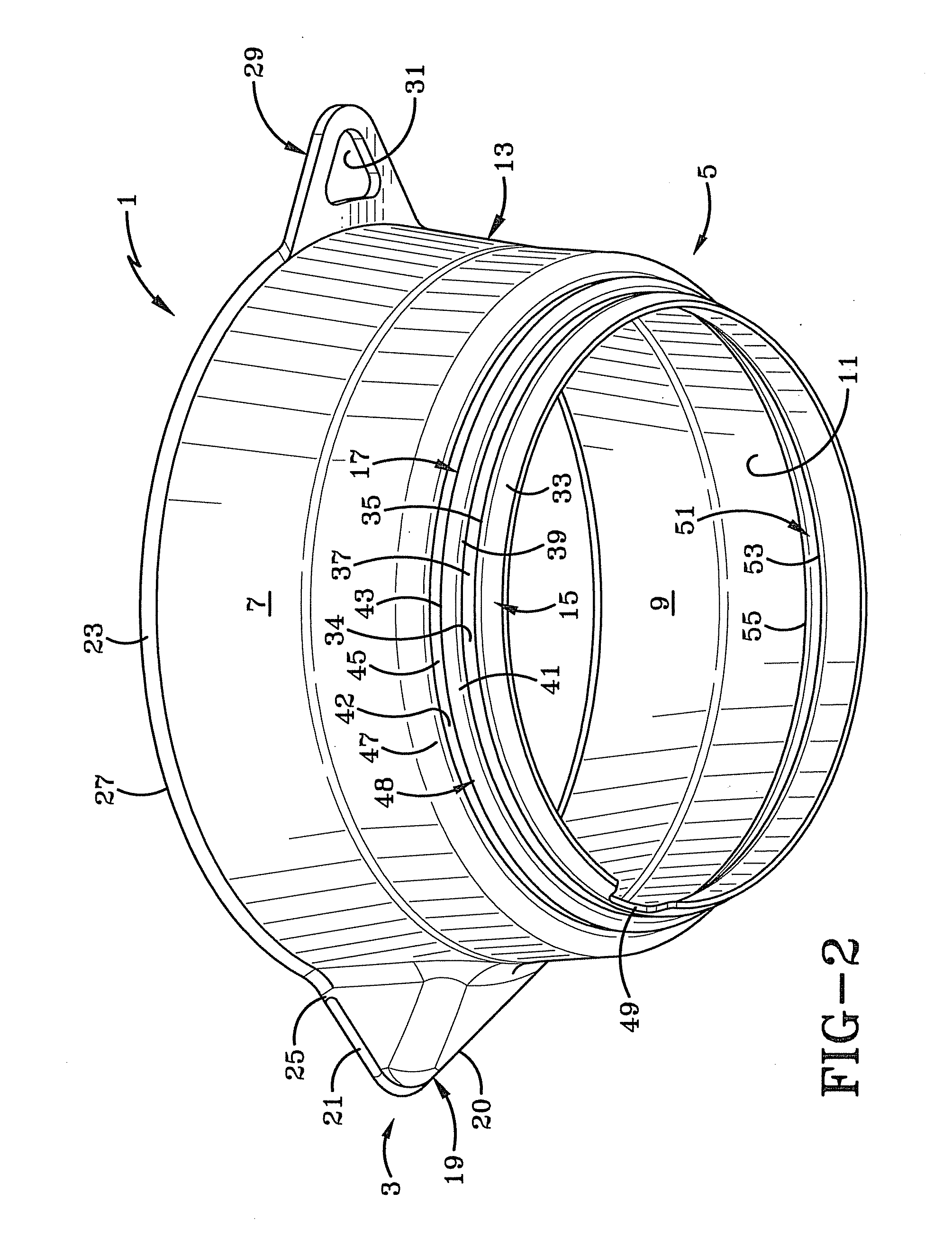

[0026]The paint can extender of the present invention is shown in FIGS. 1-13 and is indicated generally at 1. As shown in FIGS. 1-3, paint can extender 1 is integrally molded of a plastic material and is formed as a one-piece member, and has a generally cylindrical shape which includes an upper end 3, a lower end 5, an outer surface 7, and an inner surface 9 defining an inner channel 11 therethrough. A main body 13 extends from two annular stepped portions proximate lower end 5, whereby the two annular stepped portions define a first connection member 15 and a second connection member 17. Proximate upper end 3, main body 13 includes a pour spout 19 defined by an angled surface 20 and a pour lip 21.

[0027]As shown in FIGS. 1-4, main body 13 terminates proximate upper end 3 in a flared edge 23 which extends substantially around the periphery of the top-most portion of paint can extender 1 terminating at pour lip 21. Flared edge 23 is defined by the intersection of outer surface 7 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com