Profile control method for immobile string of injection well

A technology for separating injection wells and moving pipes, which is used in earth-moving drilling, wellbore/well components, and production fluids, etc. The effect of avoiding back-spitting of blocking agent and saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

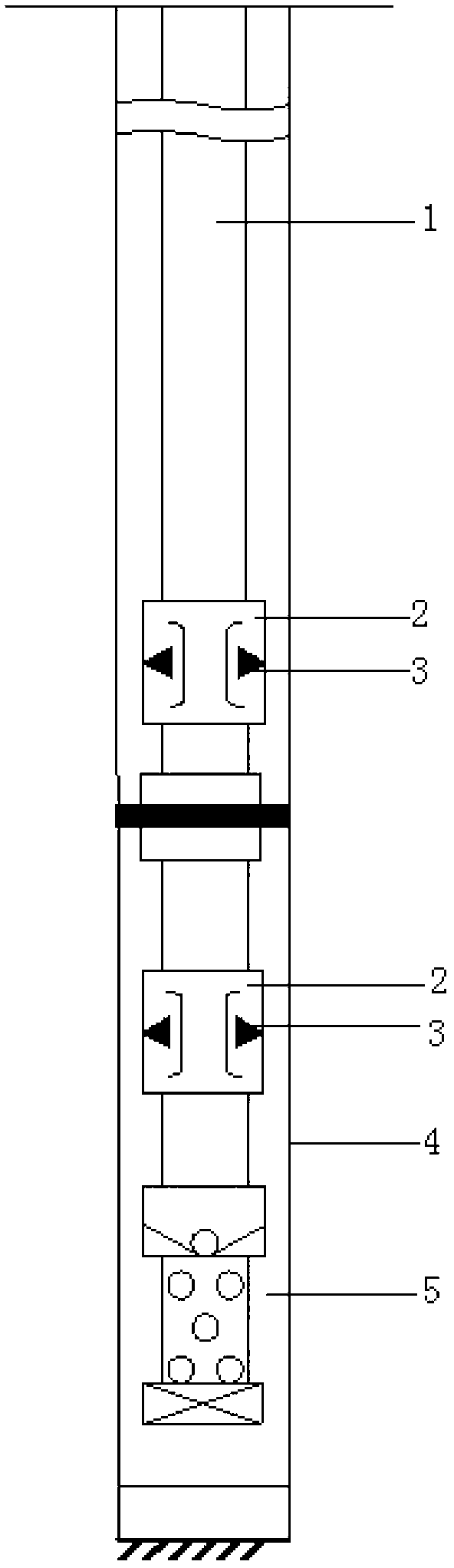

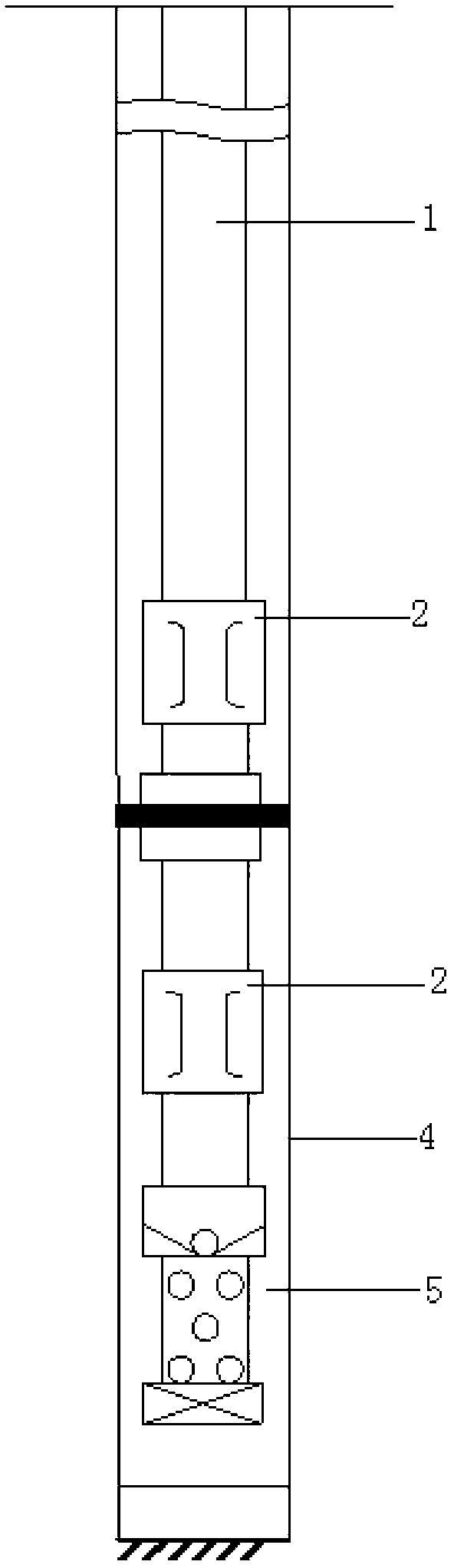

[0017] see figure 1 , is a structural schematic diagram of a water injection string in a separate injection well provided by the embodiment of the present invention. Before the profile control construction, all the water nozzles 3 on the eccentric water distributor 2 are picked up, which is the profile control string of the separate injection well. see figure 2 . Inject 30 cubic meters of clean water from oil pipe 1, and then inject high-viscosity temporary plugging agent from oil pipe 1; Temporarily block the space between the tubing 1 and the annulus 5 of the oil jacket to prevent subsequent plugging agents from settling therein. Then, inject gel particles, inorganic gel, and weak gel as plugging agents sequentially from oil pipe 1; the total amount of gel particles, inorganic gel, and weak gel is calculated by V=πR 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com