Electromagnetic flowmeter and determinator

An electromagnetic flowmeter and electrode technology, which is applied in the application of electromagnetic flowmeters to detect fluid flow, volume/mass flow generated by electromagnetic effects, etc., can solve problems such as gasket damage, gasket loss of shrinkage space, extrusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

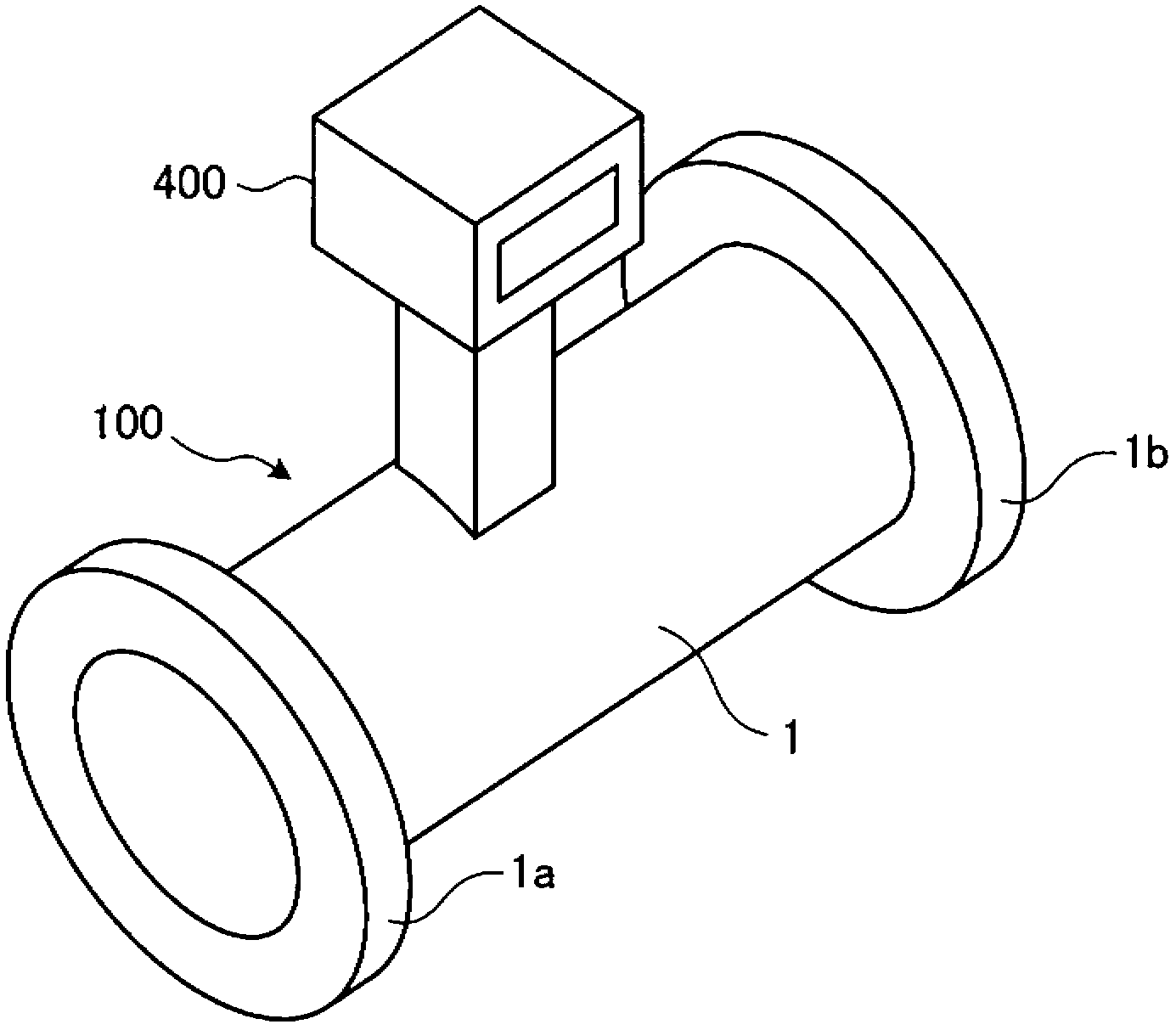

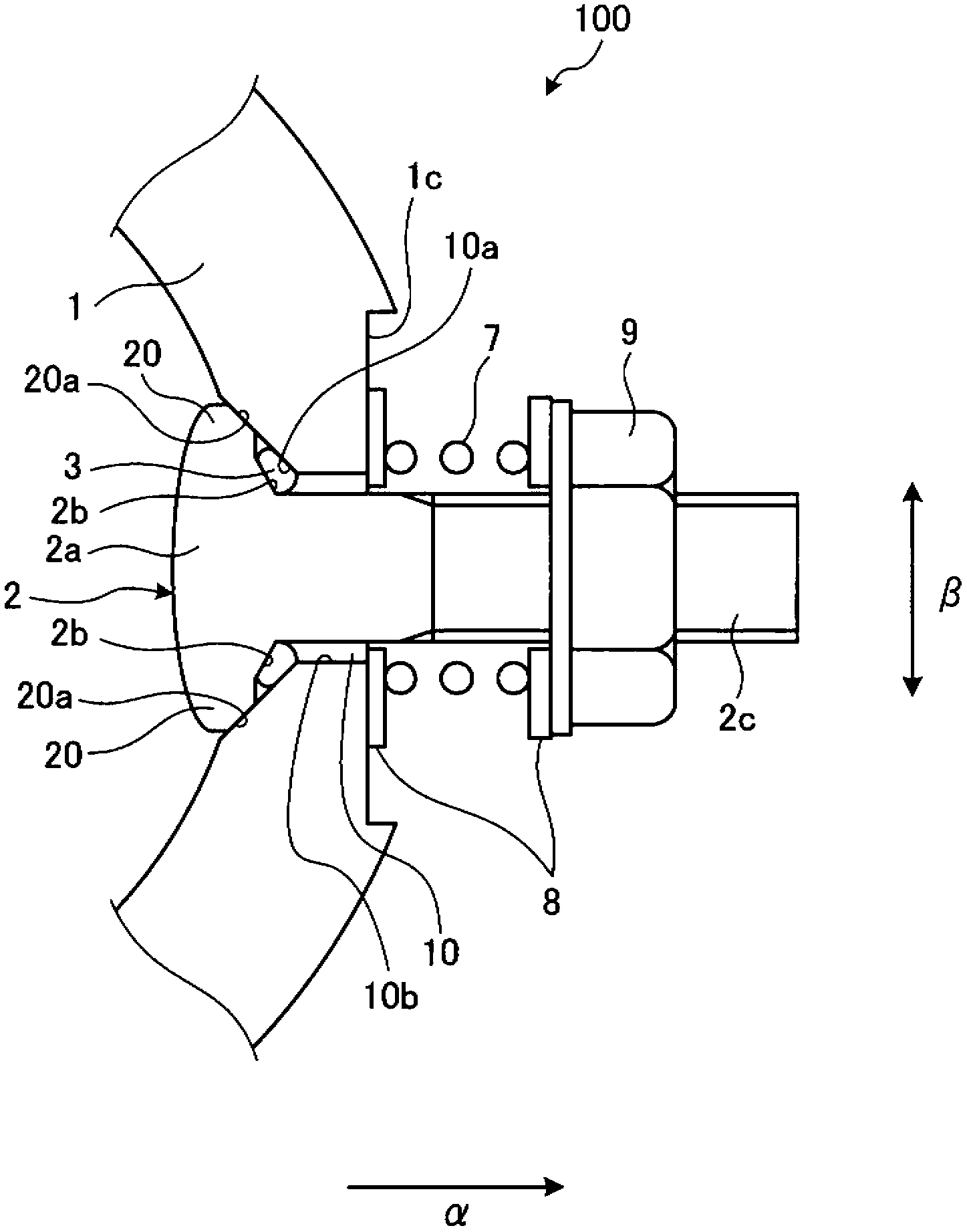

[0017] figure 1 It is an external perspective view of the measurement device of the first embodiment. Such as figure 1 As shown, the measurement device is used to measure the flow rate of a fluid as an object to be measured, and is composed of an electromagnetic flowmeter 100 and a control unit 400 . The electromagnetic flowmeter 100 is provided with: a measuring tube 1 through which a fluid as an object to be measured flows, and a pair of electrode members 2 facing the peripheral wall of the measuring tube 1 (see figure 2 ). In addition, flanges 1a and 1b for connecting to piping not shown are provided at both ends of the measuring tube 1 . The control unit 400 is integrally formed with the electromagnetic flowmeter 100 , and is usually installed above the measuring tube 1 of the electromagnetic flowmeter 100 .

[0018] Next, an outline of the operation of the measurement device will be described. In the measuring device, a magnetic field is formed inside the measuring ...

no. 2 approach )

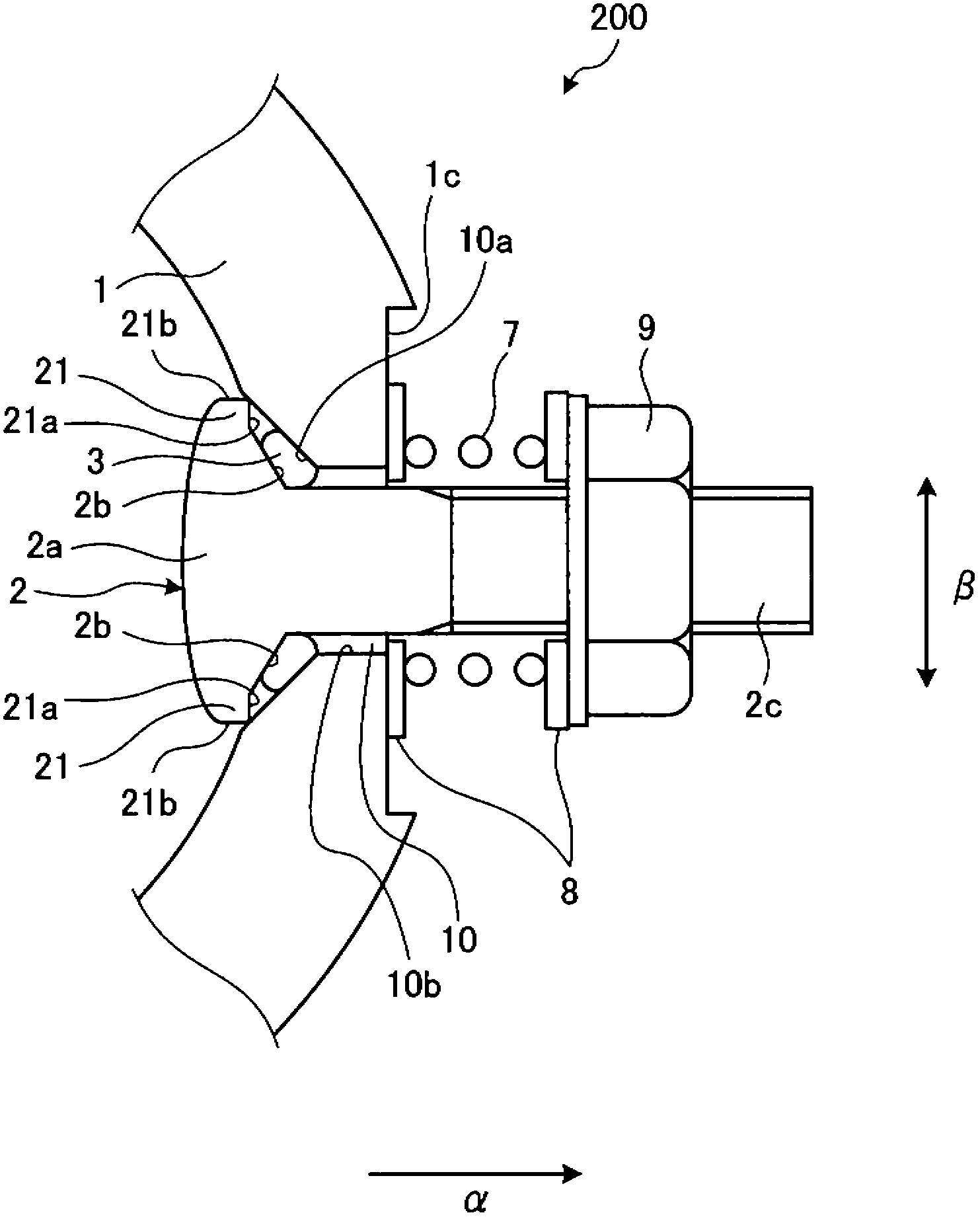

[0035] The electromagnetic flowmeter of the first embodiment is configured such that the electrode member 2 is provided with a protruding portion 20 having an inclined surface 20a in a direction intersecting the direction from the inside of the measuring tube 1 toward the outside (see figure 2 ). On the other hand, in the electromagnetic flowmeter of this embodiment, the electrode member is formed with a protruding portion that does not have the inclined surface 20a.

[0036] image 3 It is a sectional view of an electrode and its peripheral part of the electromagnetic flowmeter of the second embodiment. The electromagnetic flowmeter 200 of this embodiment mainly includes a measuring tube 1 , an electrode member 2 , a gasket 3 , a spring 7 , a spacer 8 , and a nut 9 . Here, the structures and functions of the measuring tube 1 , the washer 3 , the spring 7 , the spacer 8 , and the nut 9 are the same as those of the first embodiment, and therefore description thereof will be ...

no. 3 approach )

[0047] The electromagnetic flowmeter of the first embodiment is configured such that the electrode member 2 is provided with a protruding portion 20 having an inclined surface 20a in a direction intersecting the direction from the inside of the measuring tube 1 toward the outside (see figure 2 ). On the other hand, in the electromagnetic flowmeter of the present embodiment, the electrode member is formed with a protruding portion protruding in a direction from the inside of the measuring tube toward the outside.

[0048] Figure 4 It is a sectional view of an electrode and its peripheral part of the electromagnetic flowmeter of the third embodiment. The electromagnetic flowmeter 300 of this embodiment mainly includes a measuring tube 1 , an electrode member 2 , a gasket 3 , a spring 7 , a spacer 8 , and a nut 9 . Here, the structures and functions of the measuring tube 1 , the washer 3 , the spring 7 , the spacer 8 , and the nut 9 are the same as those of the first embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com