An external motor rotor bldc motor for a drum washing machine

A drum washing machine and motor rotor technology, applied to synchronous motors with stationary armatures and rotating magnets, electric components, electromechanical devices, etc., can solve the problem of small output torque, achieve the elimination of sliding wear, high energy conversion efficiency, The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

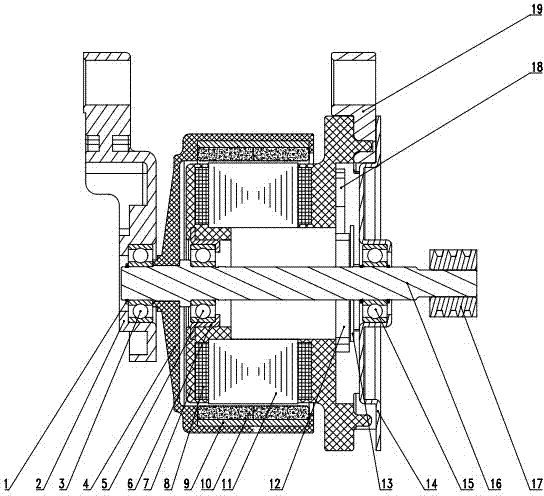

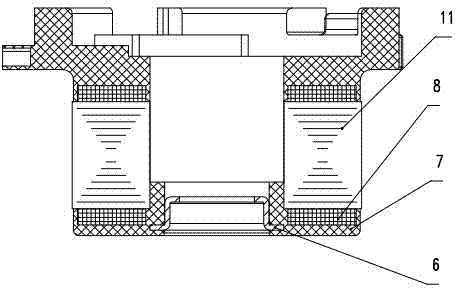

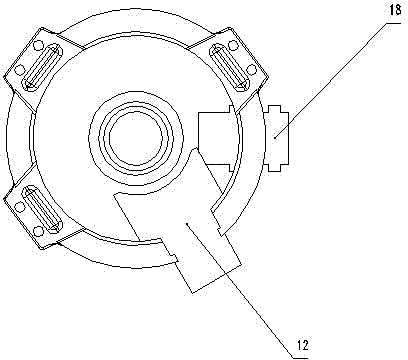

[0027] Such as Figure 1 to Figure 4 Shown is the structural representation of the present invention,

[0028] The reference signs therein are:

[0029] Open retaining ring 1, fixed bracket 2, third bearing 3, motor rotor 4, first bearing 5, first end cover 6, motor stator 7, electromagnetic coil 8, magnetic ring 9, permanent magnet 10, iron core 11, Hall element feedback assembly 12 , magnetic disk 13 , second end cover 14 , second bearing 15 , rotating shaft 16 , pulley 17 , lead wire assembly 18 , and fixed foot 19 .

[0030] Such as Figure 1 to Figure 4 as shown,

[0031] An outer motor rotor BLDC motor for a drum washing machine of the present invention includes a rotating shaft 16 with a pulley 17 installed at the right end, and is characterized in that it also includes a first end cover 6 and a second end cover 14, on which an elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com