Making process of black tea

A processing technology and technology of black tea, applied in the direction of tea treatment before extraction, etc., can solve the problems of low black tea output, high price, and inability to meet the needs of industrial products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

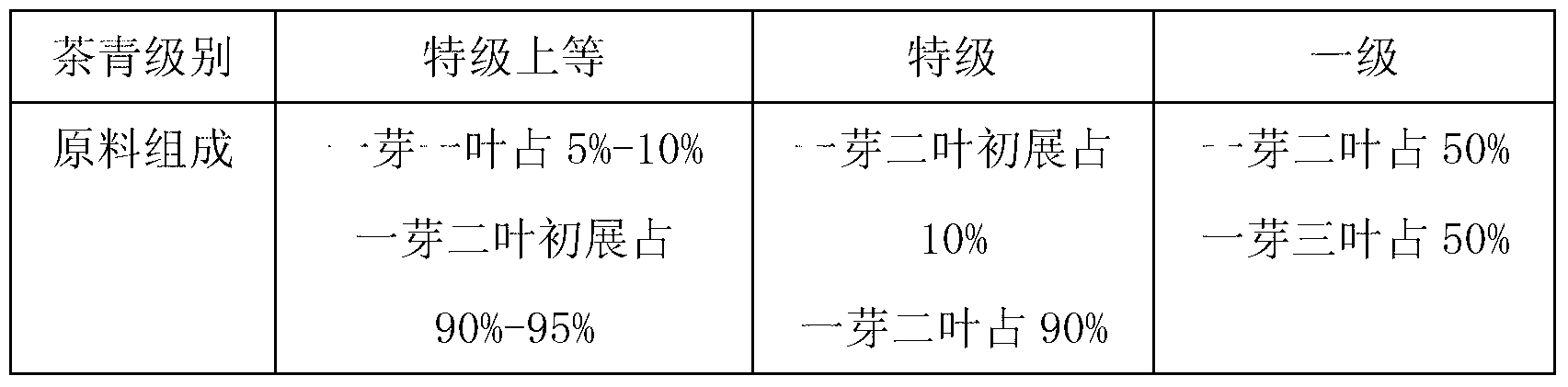

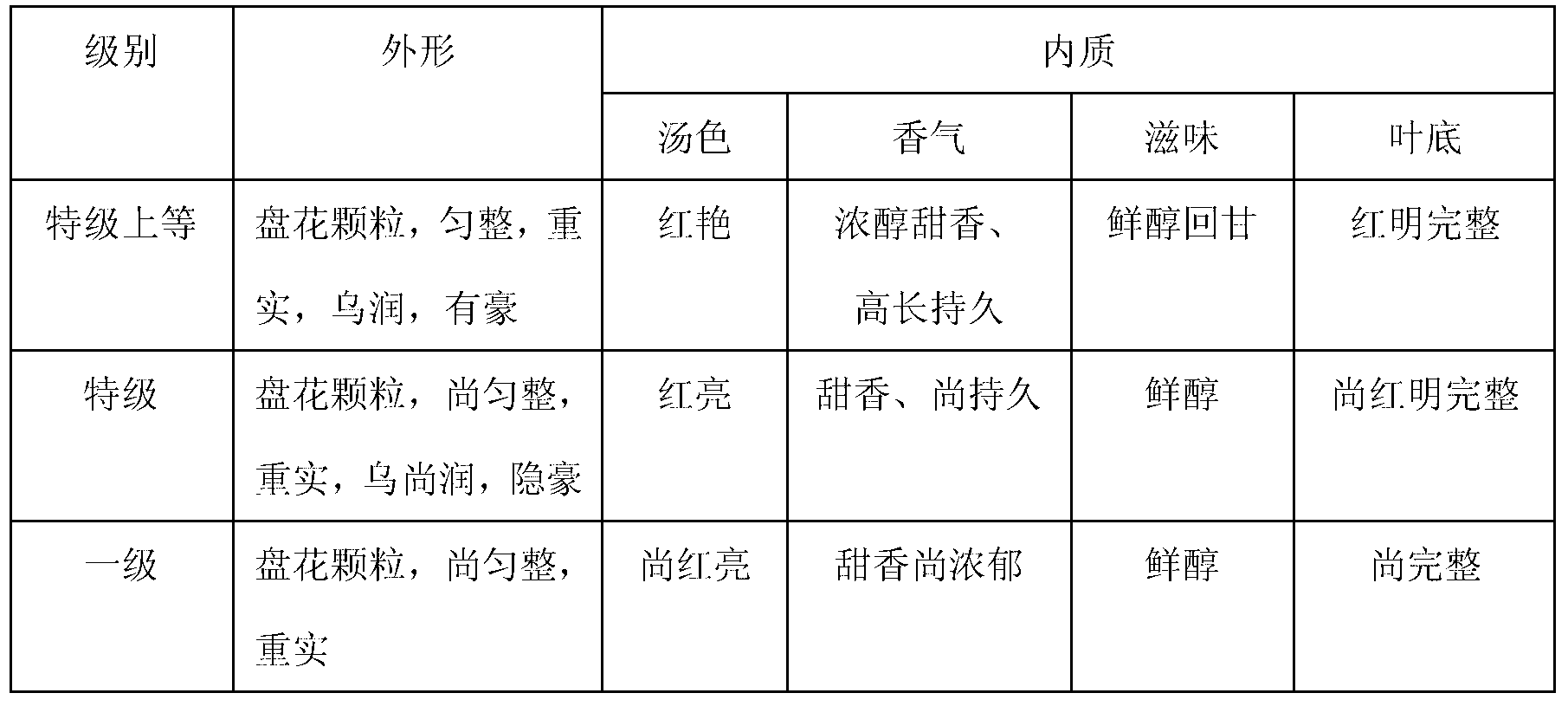

Method used

Image

Examples

Embodiment 1

[0036] Described black tea is made according to the following steps:

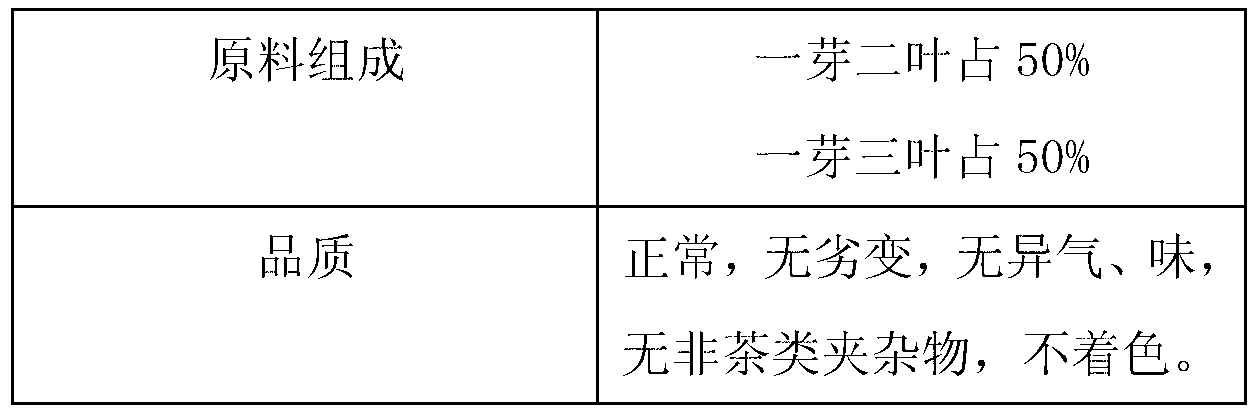

[0037] A Withering: Take fresh leaf materials containing one bud, two leaves, and three leaves, and place them in a withering tank with a thickness of 10cm. The hot air withering temperature is 30°C, and the withering time is 24 hours. During this period, shake once every 2 hours. , until the water content is 60-62%;

[0038] B Kneading: Under the conditions of temperature 20-24°C and humidity 80-90%, use 6CR-55 kneading machine to knead. The loading capacity of each tube is 30kg. 35 rpm, kneading time is 90 minutes, knead until the tea strips are tightly rolled, the tea juice is fully kneaded without loss, the leaves are partially red, and emit a strong fragrance, the strip forming rate reaches 95%, and the cell destruction rate If it reaches 78-85%, it is appropriate to knead. After the kneading is completed, get off the machine in time to deblock, put it in a bamboo basket, and transport it to the ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com