Punching and cutting rivet

A technology of rivets and nail mandrels, which is applied in the direction of rivets, thin-plate connections, and connecting components, can solve problems such as production difficulties, lower production efficiency, and drilling processing difficulties, so as to solve processing difficulties, improve production efficiency, reduce labor intensity and The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

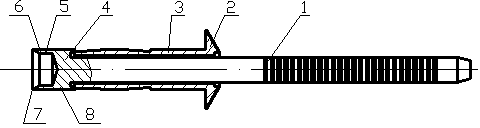

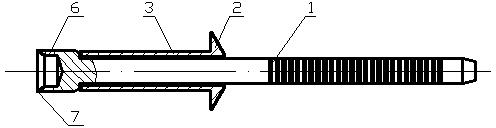

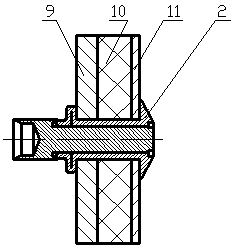

[0022] Such as figure 1 , image 3 , Figure 5 As shown, the reserved hole is processed at the same time after the pressing plate and the riveted workpiece are pressed to ensure the concentricity of the reserved hole, and then a flexible material pad is placed between the pressing plate and the riveted workpiece; body, insert the mandrel rod into the nozzle of the riveting tool, align the head of the mandrel cap with the reserved hole on the pressure plate, and make the piercing cutting edge vertically press the flexible material pad, push forward with force, and the piercing and cutting edge cuts Wear a flexible material pad, and then pull the riveting after the mandrel cap head compacts the riveted workpiece. The mandrel cap head and part of the pipe body pass through the pressing plate, the flexible material pad and the riveted workpiece are locked together. Since there is a countersunk hole in the cap head of the nail core, the end face of the countersunk hole is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com