Uniform lubricating system of high-speed rolling bearings

A lubrication system and high-speed rolling technology, which is applied in the field of bearing lubrication system and uniform lubrication system of high-speed rolling bearings. It can solve problems such as temperature rise, affecting bearing performance, burning, etc., achieve uniform temperature distribution, improve service life and work performance , evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

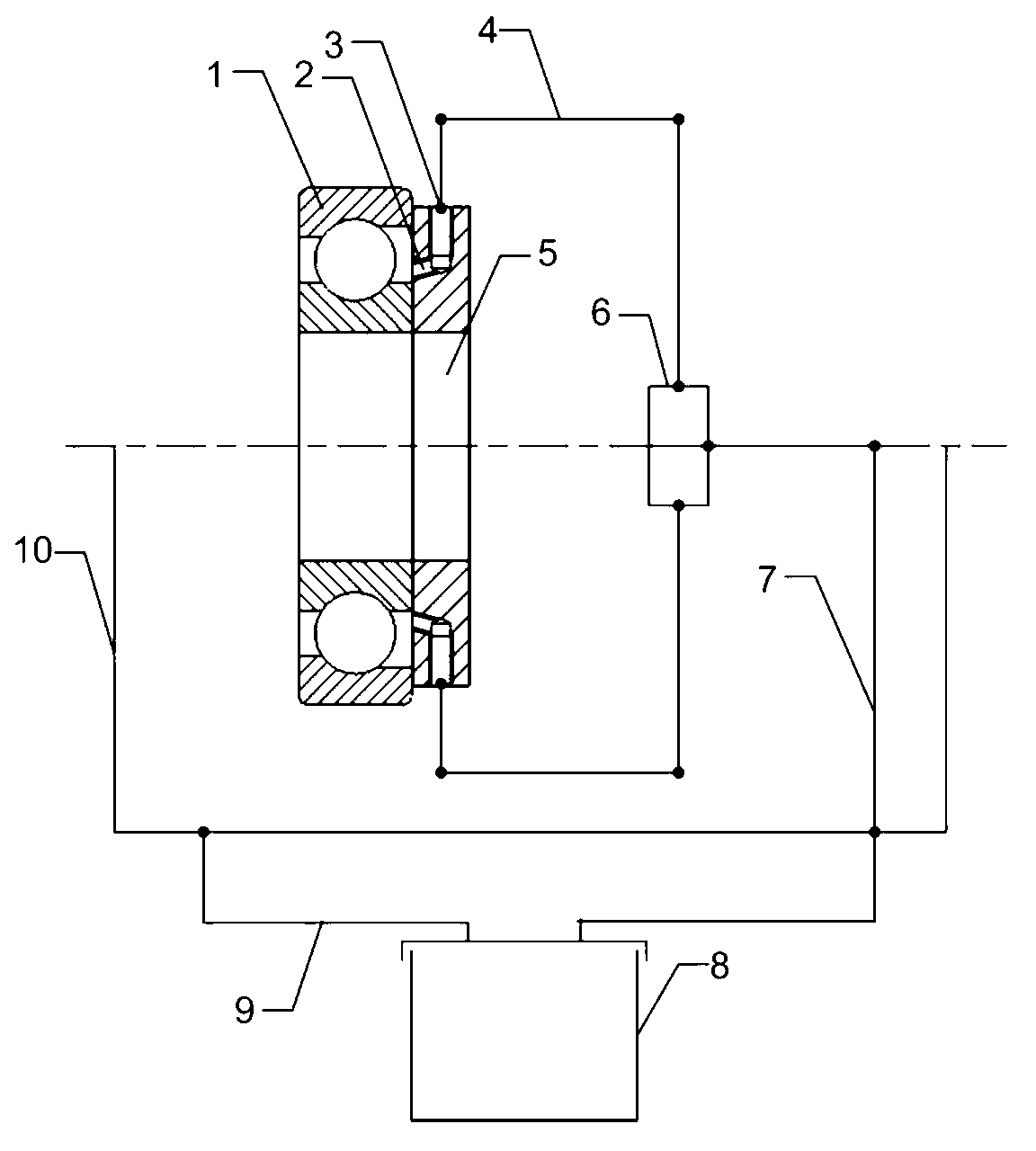

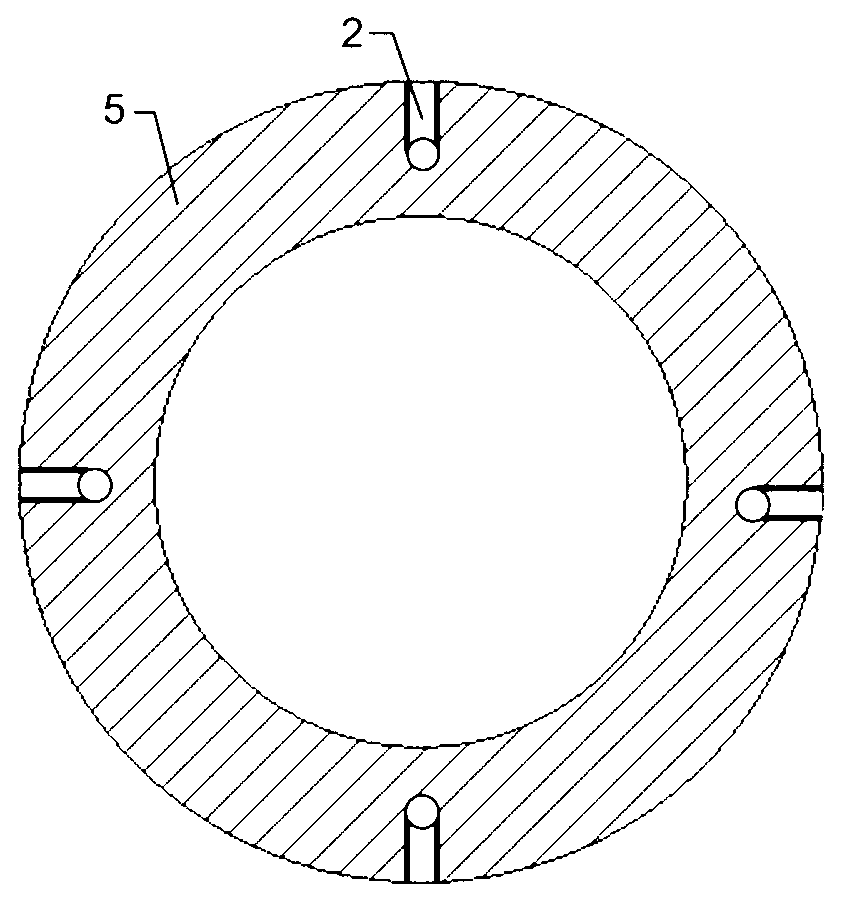

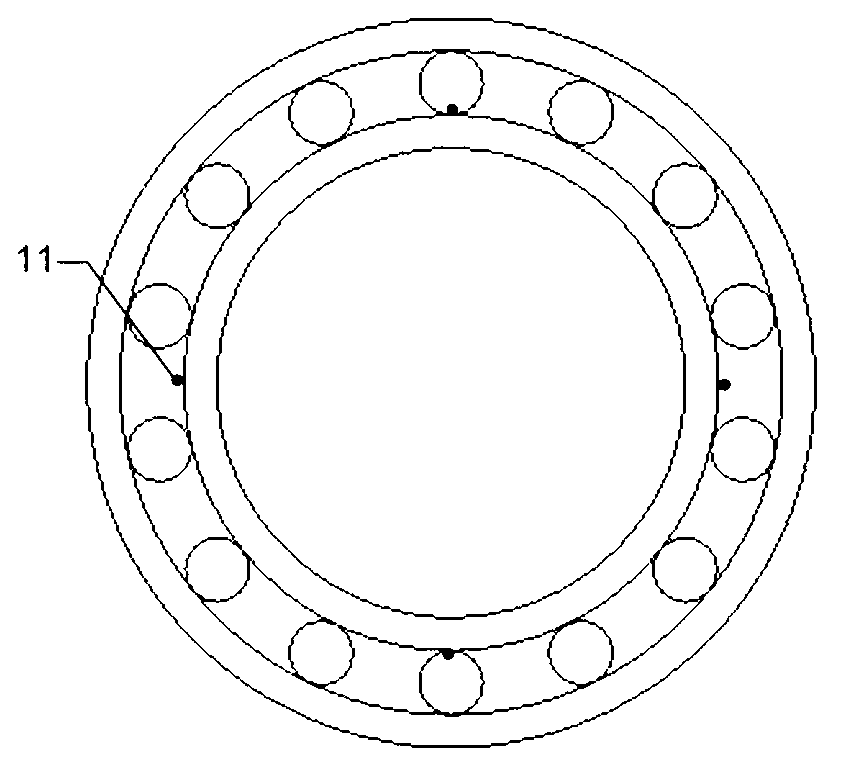

[0018] Such as figure 1 As shown, the technical solution specifically implemented by the present invention is a uniform lubrication system for high-speed rolling bearings, including bearing lubrication oil injection holes 2, lubrication nozzles 3, oil injection hole support plates 5, lubricating oil pipelines 4, and three-way valves 6;

[0019] The lubricating oil from the oil tank 8 reaches the three-way valve 6 after passing through the oil inlet pipeline 7. After passing through the three-way valve 6, the lubricating oil is divided into two paths, and then reaches the lubricating oil nozzle 3 through each oil distribution pipeline 4, and the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com