Ceramic diaphragm and application of same to lithium ion battery

A technology of ceramic diaphragm and secondary battery, applied in the field of electrochemistry, can solve the problems of affecting the performance of ceramic diaphragm, poor uniformity, powder drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

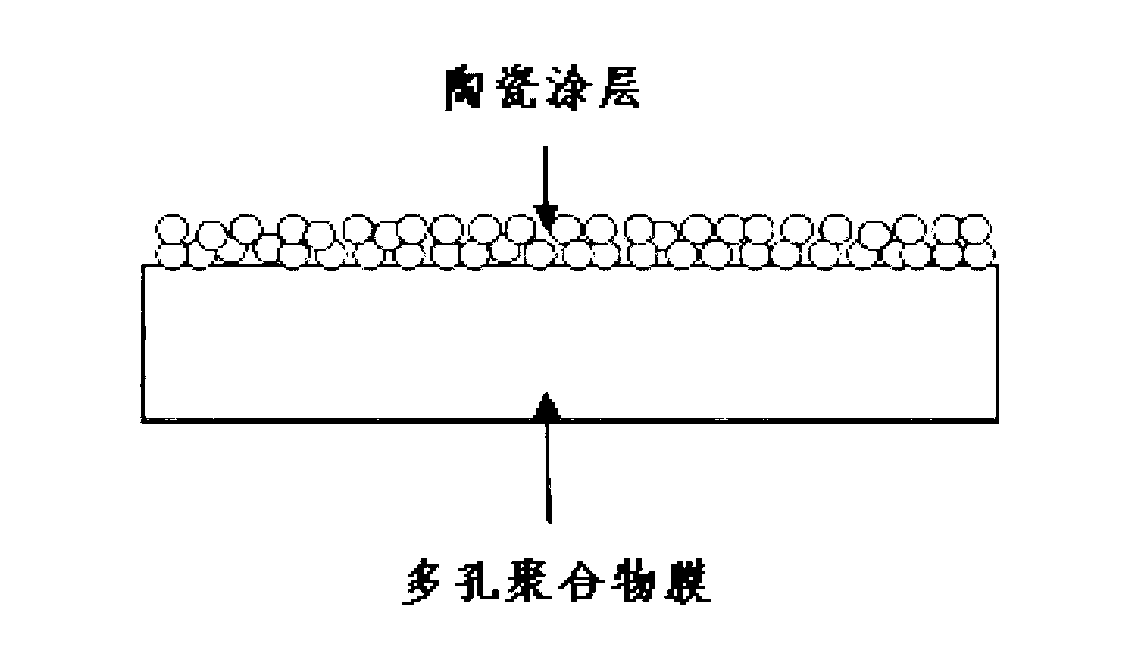

Method used

Image

Examples

Embodiment 1

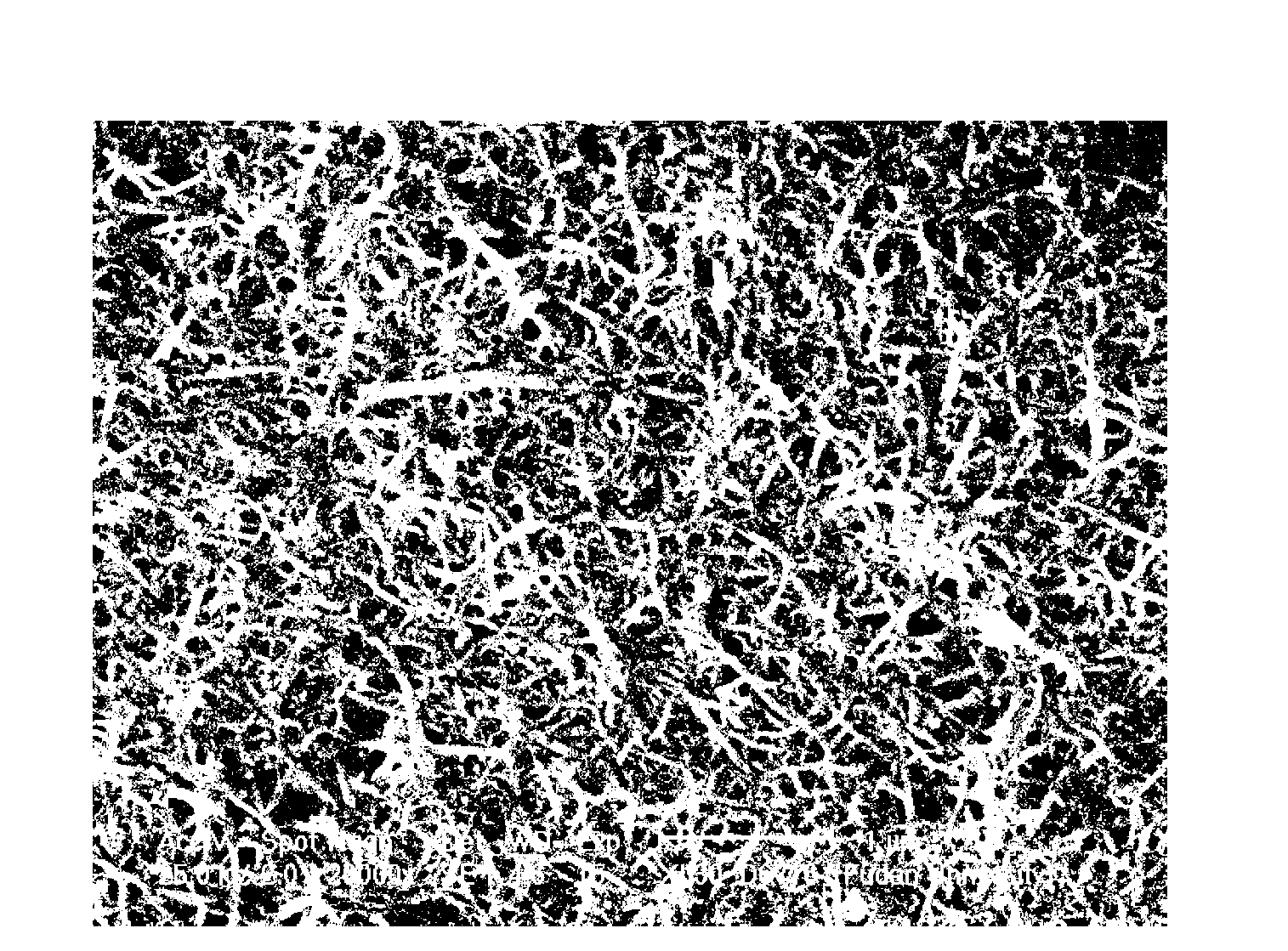

[0081] Using silica nanowires with a number-average diameter of 10 nanometers, a number-average length of about 2 microns, and an aspect ratio of about 200:1 as powder, polymethyl methacrylate as a binder is dispersed in acetone. After dispersing for 10 hours under the condition of mechanical stirring, one-side coating was carried out on the polyethylene microporous diaphragm by casting method, and dried under vacuum condition at room temperature. The scanning electron micrographs of the obtained ceramic separator are as follows: figure 2 As shown, it can be seen from the figure that the silica nanowires are uniformly coated on the surface of the polyethylene microporous membrane.

Embodiment 2

[0083] Titanium dioxide nanotubes with a number-average diameter of 5 nanometers, a number-average length of 10 microns, and an aspect ratio of 2000:1 are used as powder, and polyvinylidene fluoride is used as a binder to disperse in N-methylpyrrolidone. After dispersing for 5 hours, double-sided coating was carried out on the polyethylene diaphragm on a GTB780 type coater at a speed of 2 m / min, and a ceramic diaphragm was obtained after drying.

Embodiment 3

[0085] Aluminum oxide nanorods with a number-average diameter of 50 nanometers, a number-average length of 1 micron, and an aspect ratio of 20:1 were used as powder, and polyvinylidene fluoride was used as a binder to disperse in dimethylformamide. After dispersing for 5 hours under mechanical stirring conditions, double-sided coating was carried out on the vinylidene fluoride-hexafluoropropylene copolymer film on a GTB780 type coater at a speed of 2 m / min, and a ceramic separator was obtained after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap