Plate producing and winding control system

A control system and winding machine technology, applied in secondary battery manufacturing, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as inability to achieve process continuity, multi-manpower, material change, and time-consuming charging. , to achieve the effect of saving manpower, saving waste and saving material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0035] The film making and winding control system of the present invention is used in a fully automatic winding machine. Three independent human-machine interfaces are used to operate the positive electrode production part, negative electrode production part and battery winding part of the automatic winding machine respectively. Compared with the existing control systems of other similar automatic winding machines that use a man-machine interface to operate the whole machine, the present invention is more convenient in terms of operation.

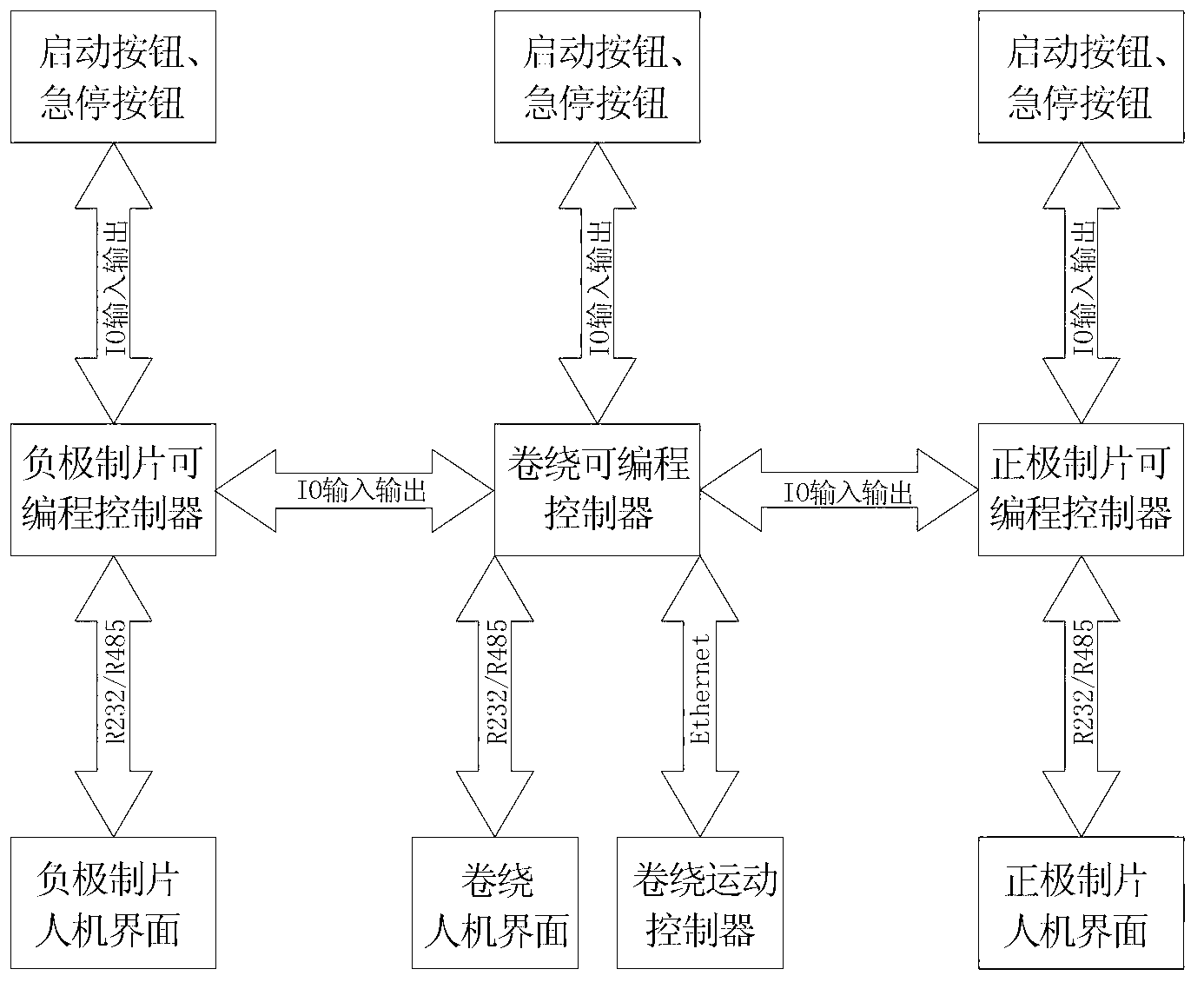

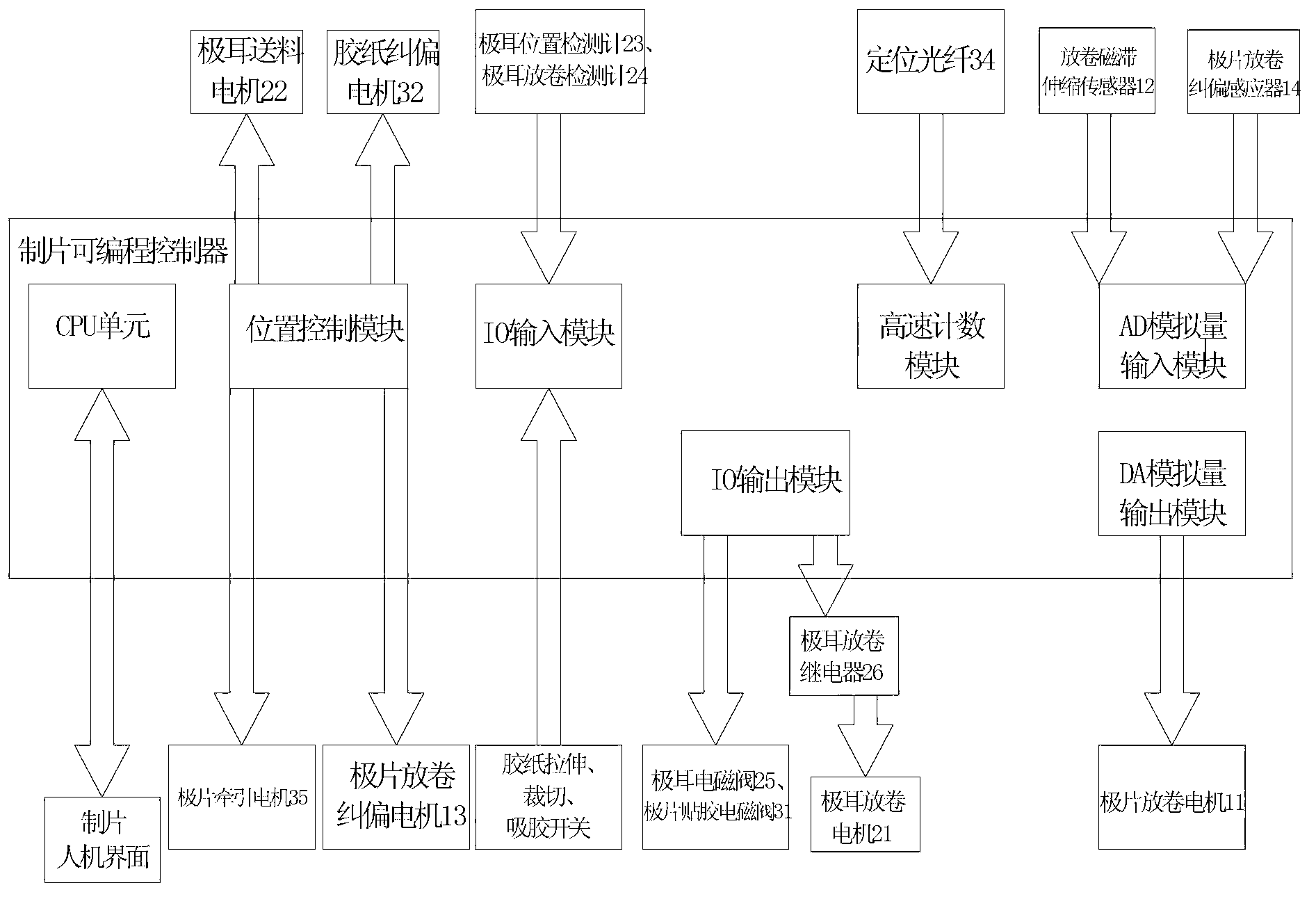

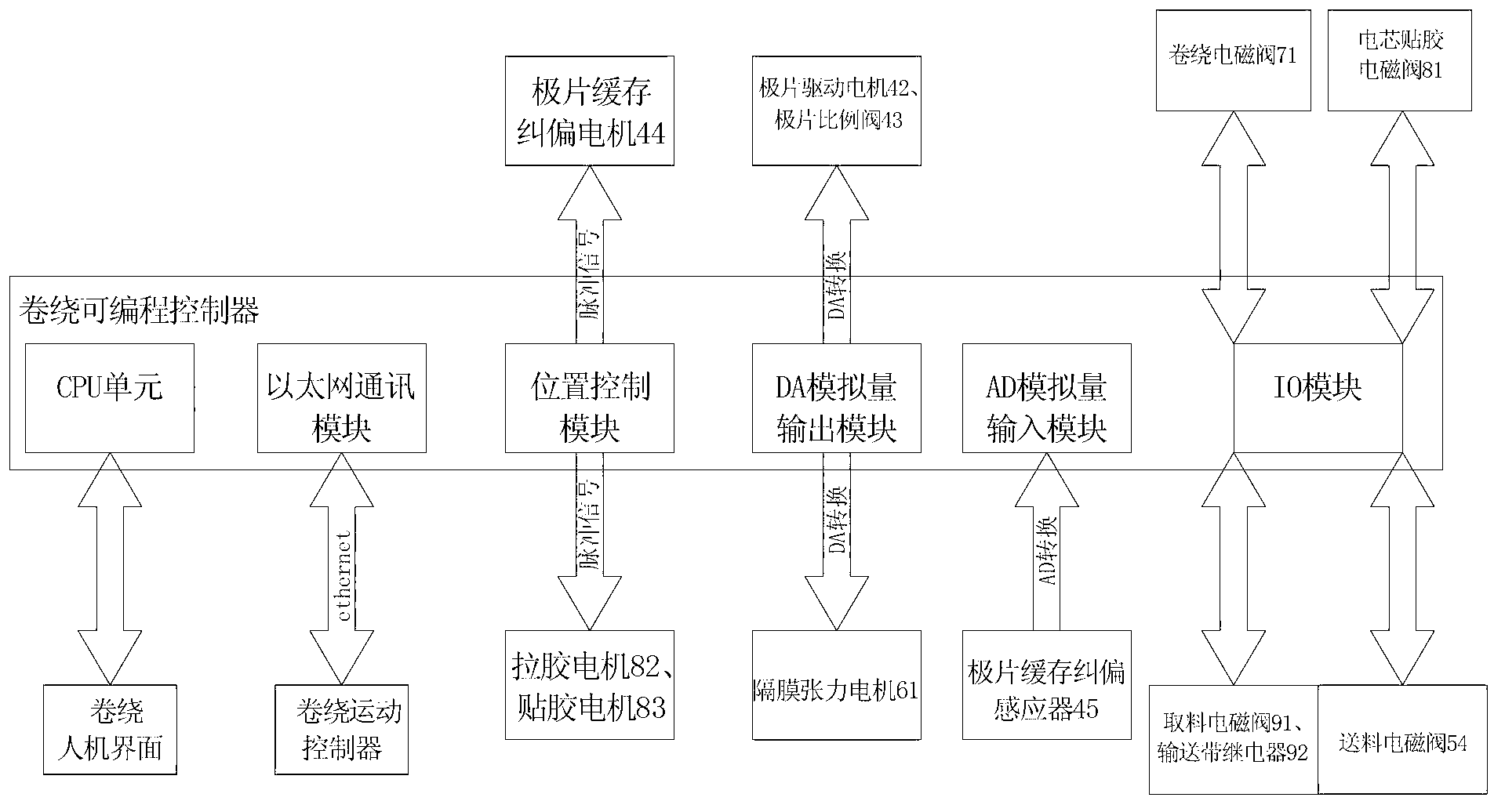

[0036] like figure 1 As shown, the positive electrode production part, the negative electrode production part and the cell winding part of the automatic winding machine are each controlled by a programmable controller, and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com