Ventilation anti-puncture working boot

A labor protection boots, puncture-proof technology, applied in boot legs, clothing, shoe uppers and other directions, can solve the problems of inconvenient wearing and walking, reduced use performance, poor adhesion performance, etc., to avoid beriberi, wear light, sticky good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

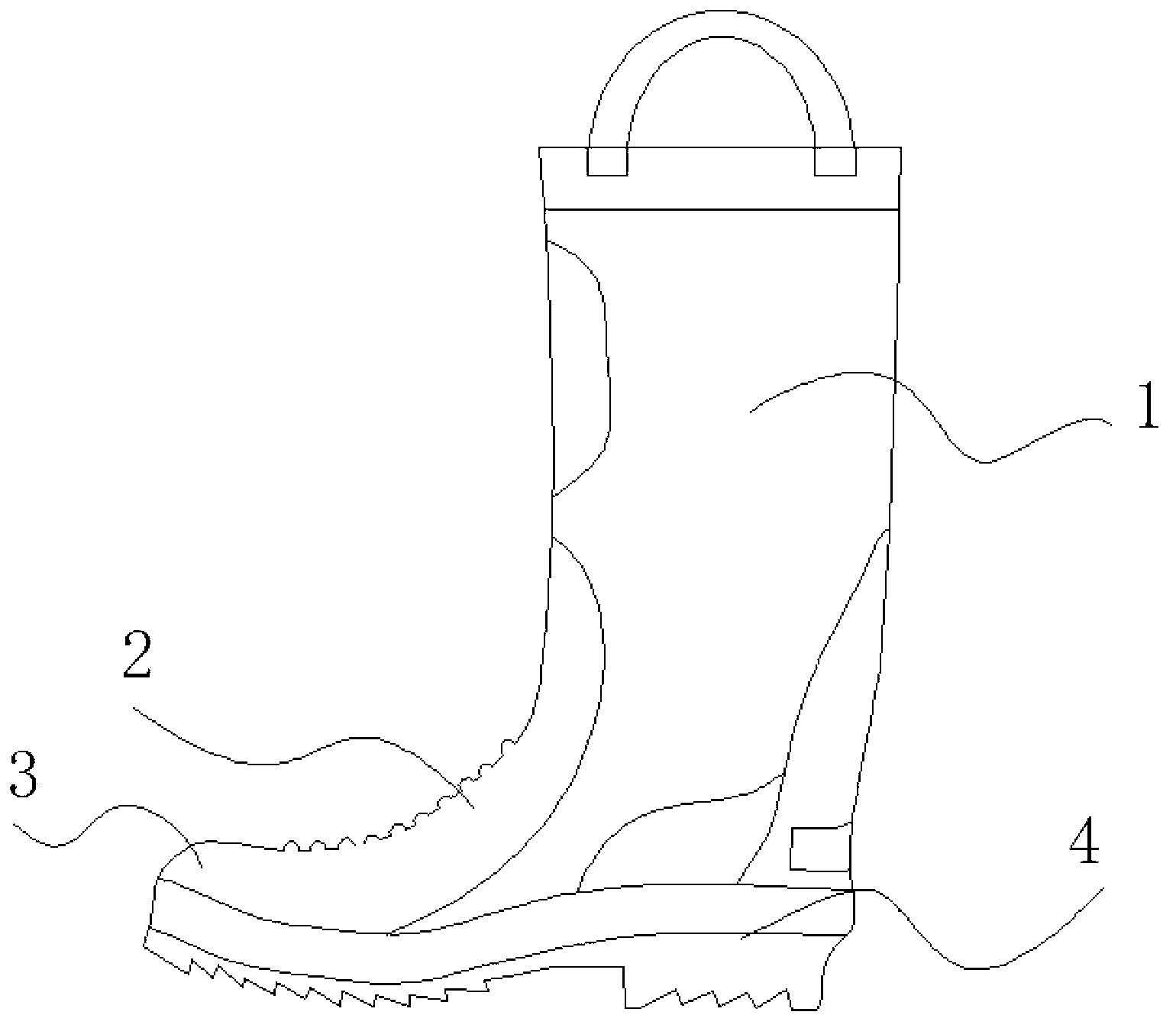

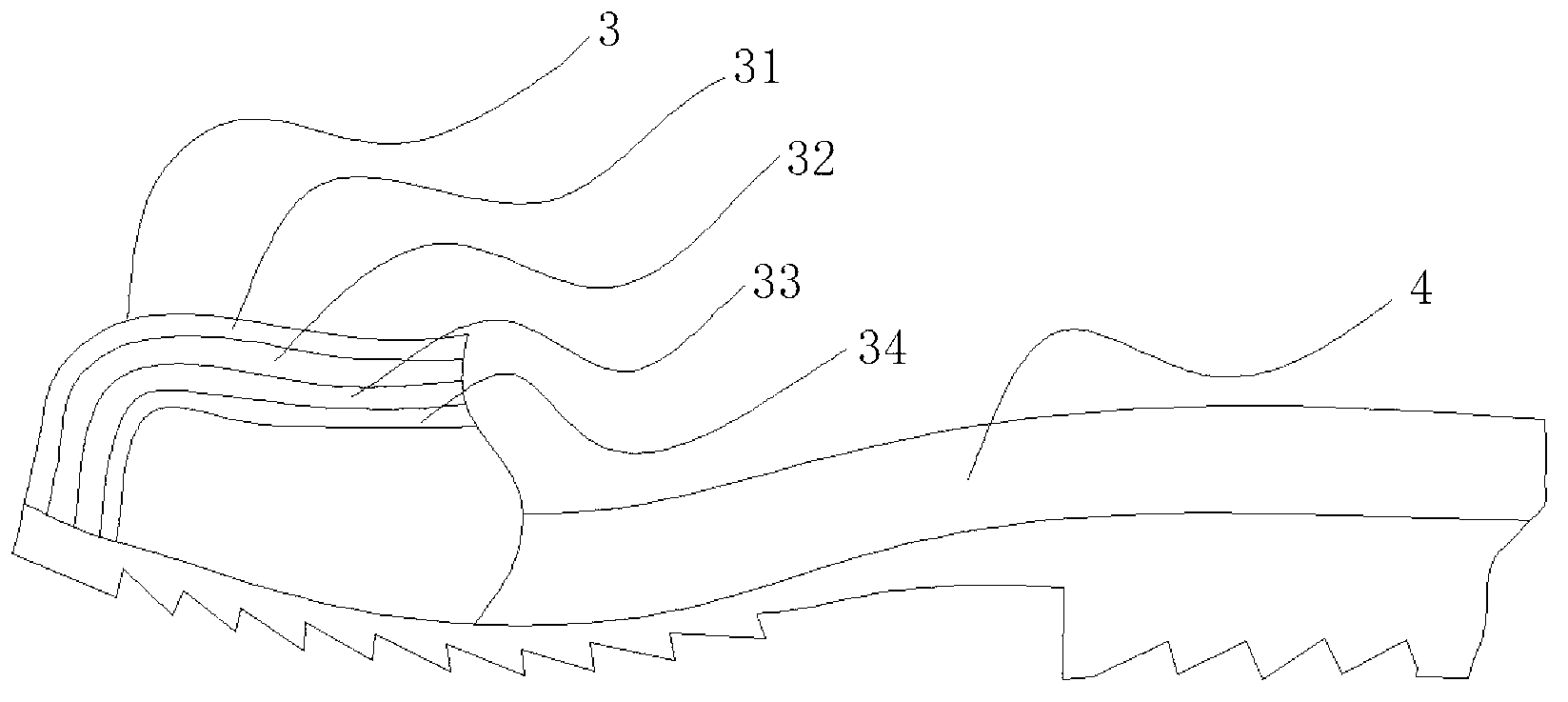

Embodiment 1

[0028] A kind of ventilated anti-puncture labor protection boots of the present embodiment, such as Figure 2-10 As shown, including the boot sole, boot toe, boot upper and boot shaft, the boot sole, boot toe, boot upper and boot shaft all include a rubber outer layer and a lining layer, the lining layer is knitted cotton, and the rubber outer layer of the boot toe The inner wall is bonded with a steel cover, the steel cover is a grid steel cover composed of three vertical ribs and three horizontal ribs, and the vertical ribs are arranged on the horizontal ribs, and the grid steel cover can withstand an impact force of not less than 250J , The pressure resistance is not less than 17KN, so it can meet the requirements of most working conditions. Since the steel cover is in the form of a mesh cover, on the one hand, it can save materials and reduce costs; on the other hand, it can reduce weight and be easy to wear. Layer bonding, the first elastic rubber layer is foam rubber, i...

Embodiment 2

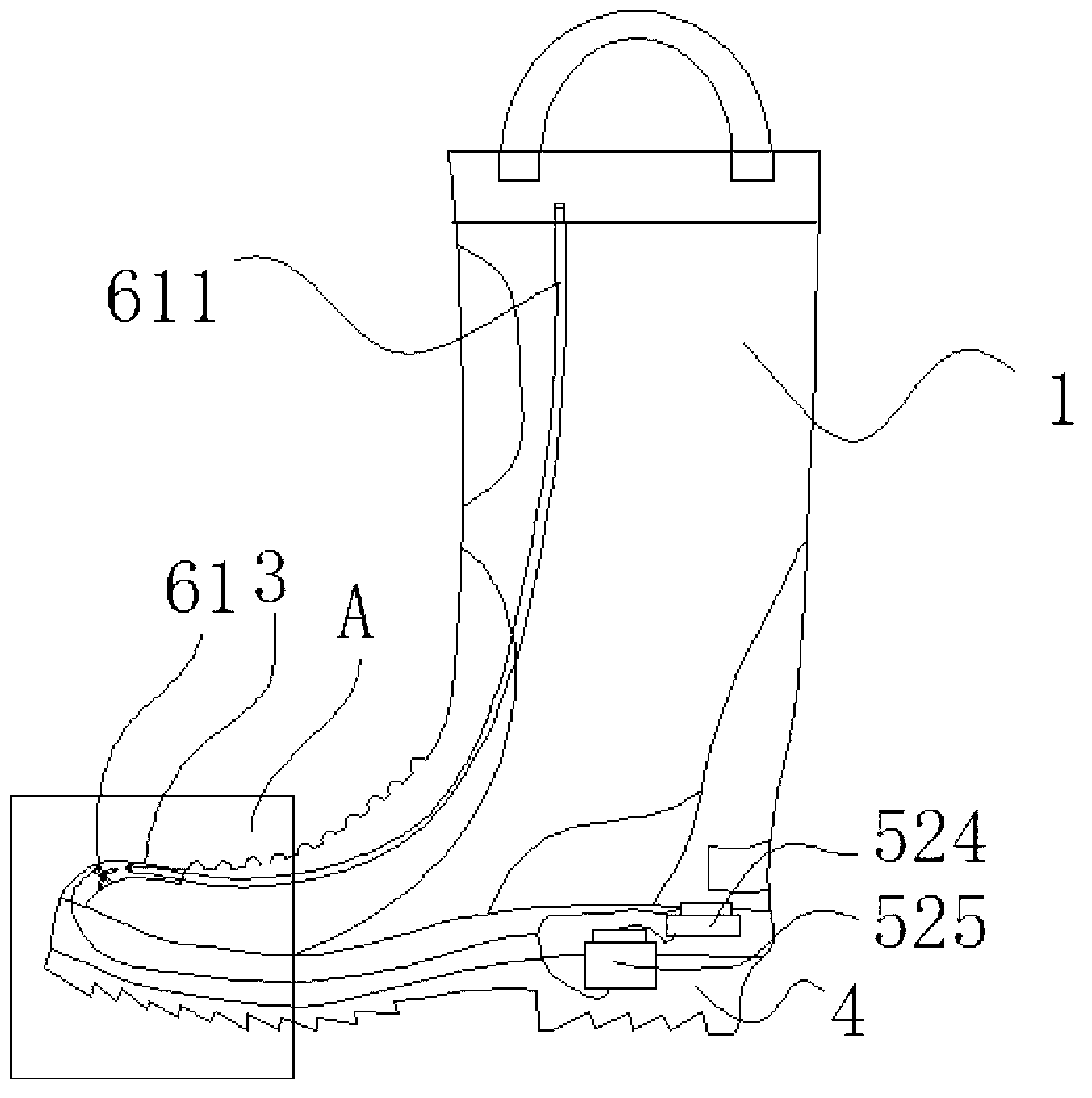

[0031] The difference between this embodiment and embodiment 1 is: as Figure 11As shown, the ventilation structure is an exhaust structure, and the exhaust structure includes an exhaust fan, a power supply and a switch. The exhaust fan, the power supply and the switch are connected in series through wires, and the power supply is arranged at the position of the heel of the boot sole. The switch is arranged at the position of the heel of the boot sole, or the switch is arranged on the boot shaft, the bonding part of the boot shaft is located at the rear side wall of the boot shaft, and the exhaust fan is arranged on the rear side wall of the boot shaft, because The rear side wall is the bonding place when the boot shaft is made, so it has high rigidity and can support the weight of the exhaust fan, so no additional supporting parts are needed. In order to better achieve the effect of ventilation, add an air intake pipe and an air outlet pipe, the air inlet of the air intake pi...

Embodiment 3

[0033] The difference between this embodiment and the above-mentioned embodiment is that: Figure 12 , 13 As shown, the ventilation structure is an air bag air supply structure, and the air bag air supply structure includes an elastic air bag, a one-way inlet valve, a one-way air outlet valve, more than one elastic conduit, the toe of the boot toe and the sole One or more air exchange holes are provided, preferably, an air exchange hole is provided on the toe of the boot, and an air exchange hole is provided on the toe of the boot sole. The air exchange hole, the one-way air intake valve and the elastic The air inlet of the airbag is connected in series through a conduit, and one or more air outlet holes are arranged on the top of the boot, and the air outlet, the one-way outlet valve, and the air outlet of the elastic airbag are connected in series through a conduit. The more air exchange holes and air outlet holes, the better the air exchange effect. When there is one elast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com