Krischner wire with sliding sleeve

A K-wire and sliding sleeve technology, applied in the field of K-wires, can solve the problems of incompatibility, reduction, and inconvenience in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

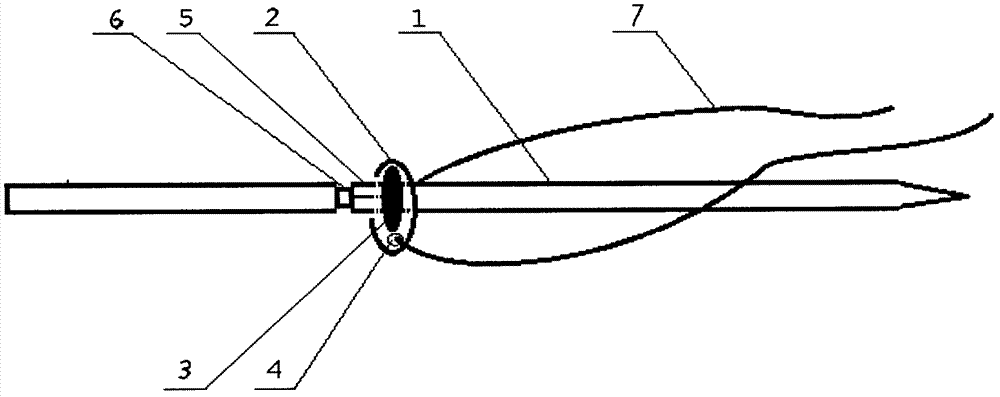

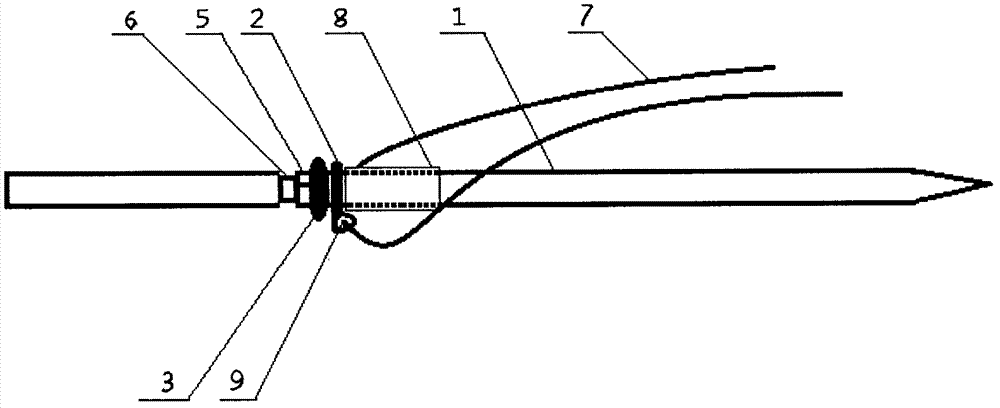

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings.

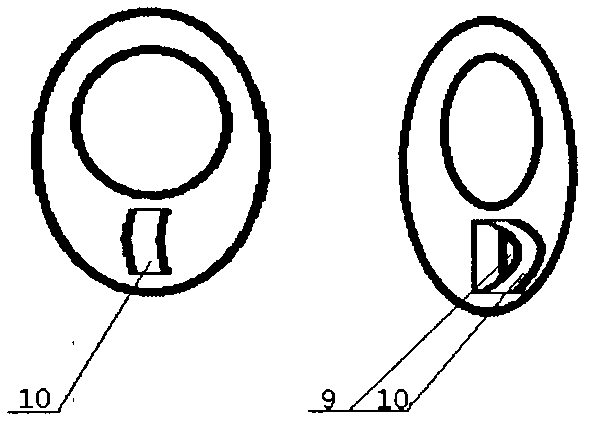

[0009] as attached figure 2 As shown, there is a boss (3) on the needle tail side of the needle body section of the Kirschner wire (1), and a small section of thread (8) protruding from the surface of the Kirschner wire on the needle tip side, between the boss (3) and the thread There is a sliding sleeve (2) between the (8), and the sliding sleeve (2) can freely rotate along the longitudinal axis of the needle body, but the sliding sleeve (2) is restricted by the boss (3) and the thread (8), and cannot rotate along the needle body. The longitudinal axis of the body moves up and down obviously, and an ear handle (10) with a hole (9) protrudes from the side of the sliding sleeve, so that the tension band material (7) can pass through the hole (9), and the end of the Kirschner wire The caudal half of the side boss (3) is a section of polyhedron (5), which is convenien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com