Surface pad assembly machine of cylindrical battery

A cylindrical battery and assembly machine technology, which is applied to equipment for manufacturing primary batteries, cylindrical shell batteries/batteries, and battery assembly machines, etc., can solve the problems of slow speed and low efficiency, and achieve the effect of improving efficiency and saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

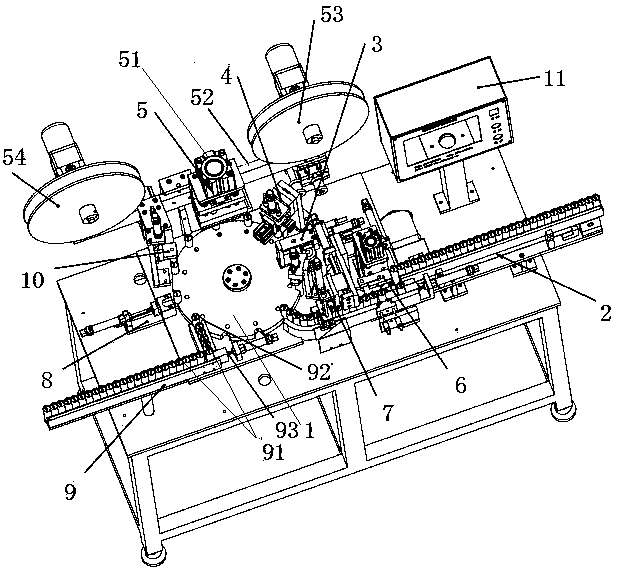

[0018] Such as figure 1 As shown, the surface pad assembly machine for cylindrical batteries disclosed in the present invention pre-places batteries with tabs and welding pins in the battery case, specifically including the indexing plate 1 installed on the frame and the battery feeding In the device 2, arc-shaped grooves for holding batteries are evenly distributed on the circumference of the index plate 1. The battery feeding device 2 includes a feeding chute 21 and a belt driven by a motor in the feeding chute. The feeding chute 21 is also equipped with an inductor for sensing the battery. On the rotating belt of device 2, the sensor senses that a battery is loaded, and the subsequent devices will work in sequence. A negative electrode lug welding device 6 and a needle pulling device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com