Collagenous fiber non-woven hydroxyapatite biological scaffold material and preparation method thereof

A technology of hydroxyapatite and hydroxyapatite, which is applied in the field of collagen fiber non-woven hydroxyapatite bio-scaffold material and its preparation, and the preparation of artificial bone repair materials, which can solve the problem of uncontrollable coating process and preparation The method process is complicated, the interface binding force is weak, etc., and the effect of enhancing biomechanical properties, excellent biocompatibility, and improving mechanical strength is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

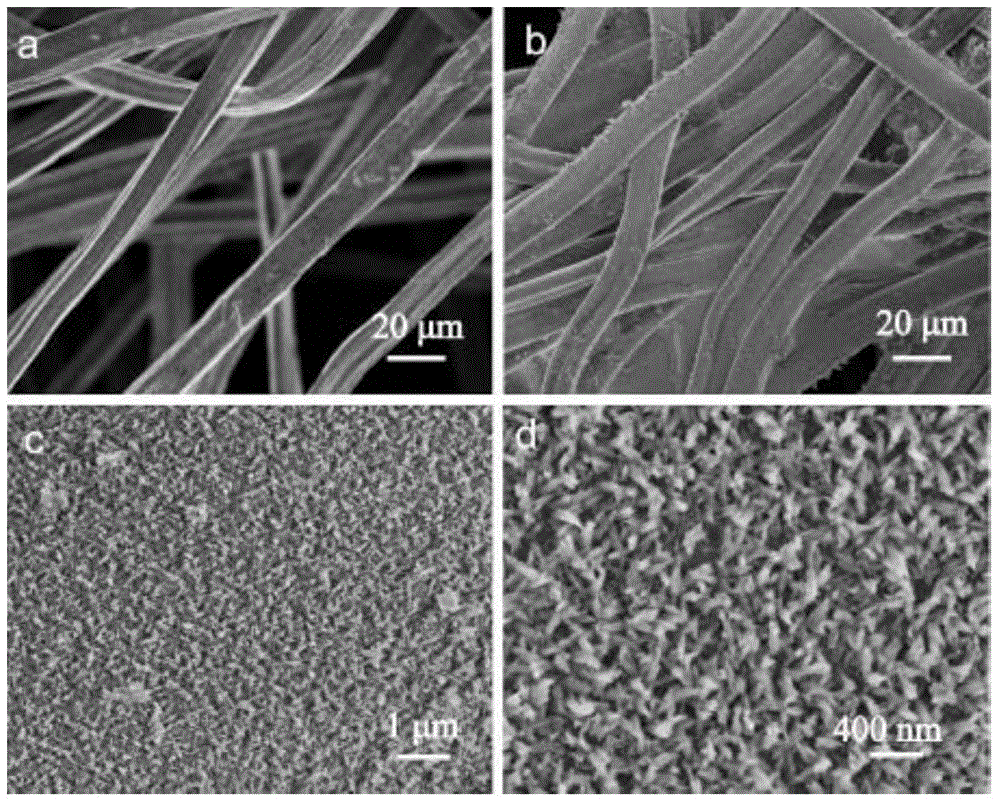

[0035] (1) Three-dimensional porous scaffolds of collagen fibers were prepared by acupuncture molding process:

[0036] 100g / m 2 After the collagen fibers are mixed and loosened, they are combed into a fiber web, and three of the fiber webs are laid in parallel so that the fibers are arranged in a longitudinal direction, and are reinforced by acupuncture. The acupuncture frequency is 1200 pricks / minute, and the acupuncture depth is 3mm. , cut the collagen fiber three-dimensional porous scaffold into the same shape as the required bone repair material, a square with a side length of 2 cm and a thickness of 3 mm, and the pore diameter of the scaffold is 20-200 μm. and dried in a drying oven at 40°C to obtain a three-dimensional porous scaffold of collagen fibers.

[0037] (2) The surface of the collagen fiber three-dimensional porous scaffold is enriched with calcium ions and phosphate ions:

[0038]Weigh 2.0g collagen and dissolve it in 100mL 4vt% acetic acid solution, stir c...

Embodiment 2

[0049] (1) Three-dimensional porous scaffolds of collagen fibers were prepared by acupuncture molding process:

[0050] 120g / m 2 After the collagen fibers are mixed and loosened, they are combed into a fiber web, and two of the fiber webs are laid in parallel so that the fibers are arranged in a longitudinal direction, and are reinforced by acupuncture. The acupuncture frequency is 1000 pricks / minute, and the acupuncture depth is 3mm. , cut the collagen fiber three-dimensional porous scaffold into the same shape as the required bone repair material, a square with a side length of 2 cm and a thickness of 3 mm, and the pore diameter of the scaffold is 40-200 μm. and dried in a drying oven at 30°C to obtain a three-dimensional porous scaffold of collagen fibers.

[0051] (2) The surface of the collagen fiber three-dimensional porous scaffold is enriched with calcium ions and phosphate ions:

[0052] Weigh 4.0g collagen and dissolve it in 100mL 4vt% acetic acid solution, stir co...

Embodiment 3

[0057] (1) The three-dimensional porous scaffold of collagen fibers was prepared by the acupuncture molding process as in Example 1.

[0058] (2) Weigh 4.0g collagen and dissolve it in 100mL 4vt% acetic acid solution, stir continuously to dissolve it completely, then weigh 1.1098g CaCl according to the calcium-phosphorus ratio of 1.67:1 2 with 0.6888g NH 4 h 2 PO 4 Dissolve in it; immerse the collagen fiber three-dimensional porous scaffold prepared in (1) into the above solution, and ultrasonically disperse it for 5 minutes, slowly pull out the scaffold at a speed of 5mm / s with tweezers, and place it in a 40°C drying oven Medium dry.

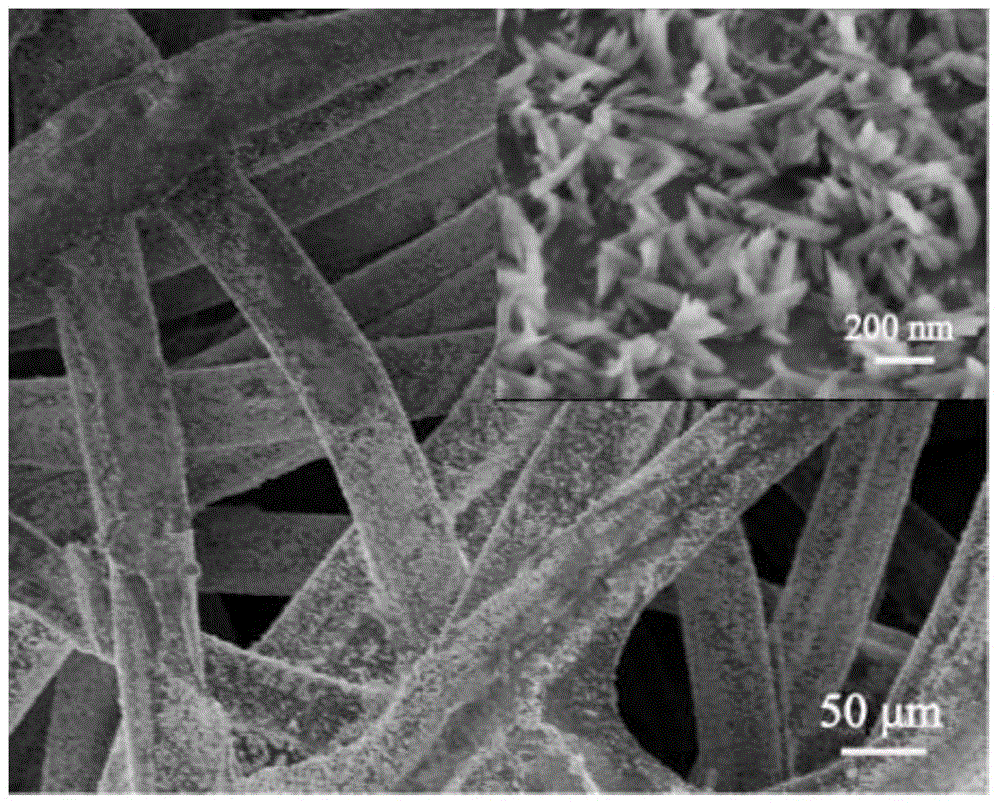

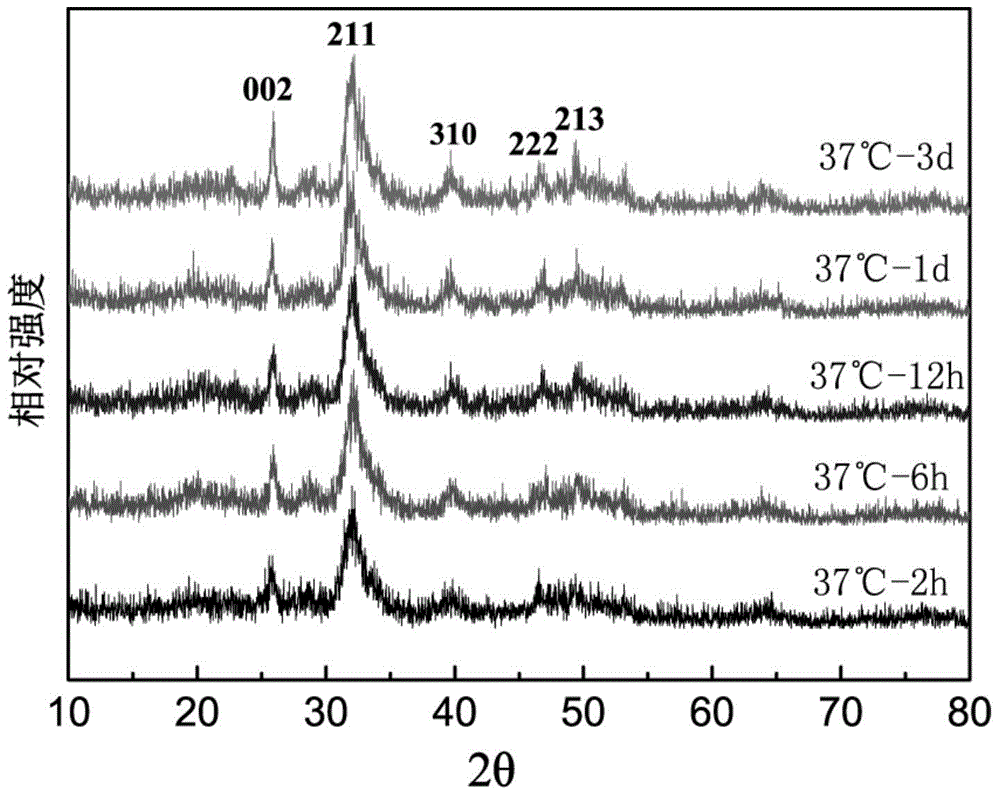

[0059] (3) Depositing hydroxyapatite on the surface of collagen fiber three-dimensional porous scaffold by biomineralization method:

[0060] Place the three-dimensional porous scaffold of collagen fibers enriched in calcium ions and phosphate ions obtained in step (2) in a medium containing 3.12g NaH 2 PO 4 2H 2 In the NaOH alkaline sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com