Material of yellow mud added with gel for preventing spontaneous combustion of residual coal

A technology of yellow mud and coal residue, applied in the field of new fire-fighting materials, can solve problems such as high operating costs, different effects, and complex technologies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

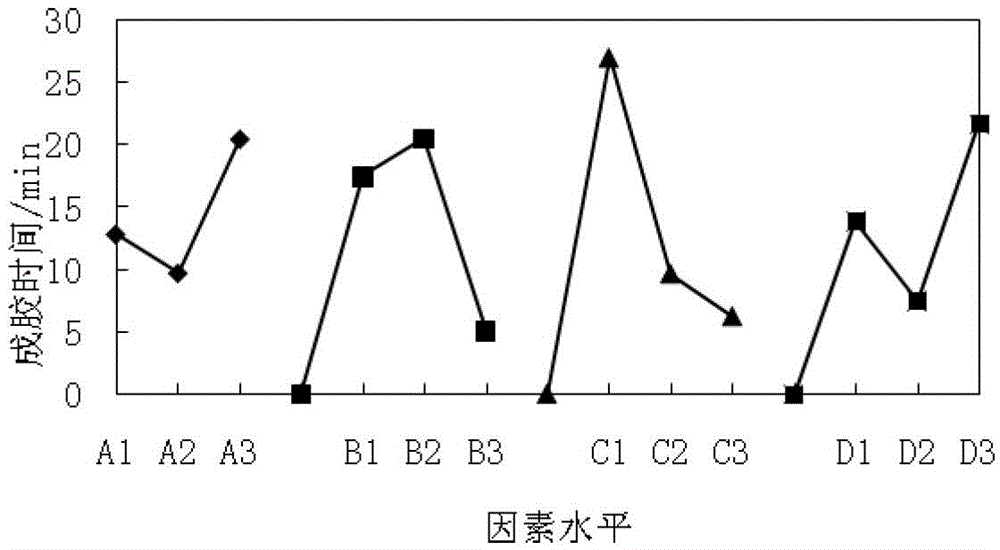

[0014] Embodiment 1: Determination of the ratio of adding gel material to yellow mud

[0015] The gel material added to yellow mud is mainly composed of yellow mud, water, coagulant, and polymer additives. The main factors that affect the gelation time of adding gel materials to yellow mud are: A—water-soil ratio, B—the amount of base material (accounting for the slurry quality), C—the amount of coagulant (accounting for the slurry quality), D— The amount of polymer additives per ‰ (accounting for the mass of the slurry), each factor takes three levels, as shown in Table 1.

[0016] Table 1 Influencing factors and factor levels of adding gel materials to yellow mud

[0017]

[0018] According to Table 1, the factors affecting the gelation time of yellow mud adding gel material and the levels of each factor, select L 9 (3 4 ) Orthogonal experiment table arrangement experiment, experiment order arrangement and the final result of each experiment are shown in Table 2 below....

Embodiment 2

[0030] Example 2: Cost Analysis

[0031] The cost of adding gel material to yellow mud is related to the requirement of gelation time during use. The gelation time is different, the ratio of materials is different, and the cost of materials used is also different. According to the optimal ratio gelling time obtained in the final experiment, when the gelling time is 3.24 minutes, the consumption and cost of raw materials for pure silicic acid gel and yellow mud slurry added gel are compared and analyzed, as shown in Table 4.

[0032] It can be seen from the calculation of the data in Table 4 that under the same gelation time, the cost of adding gel material to the yellow mud slurry with the optimal ratio is more than 25% lower than that of pure gel.

[0033] Table 4 Comparative Analysis of Cost of Colloidal Raw Materials

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com