Construction method for easy operating platform for high-altitude assembly of large-span steel truss

A technology of operating platform and steel truss, applied in the direction of house structure support, house structure support, pillars, etc., can solve the problems of increasing the amount of steel pipes, increasing the cost of measures, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

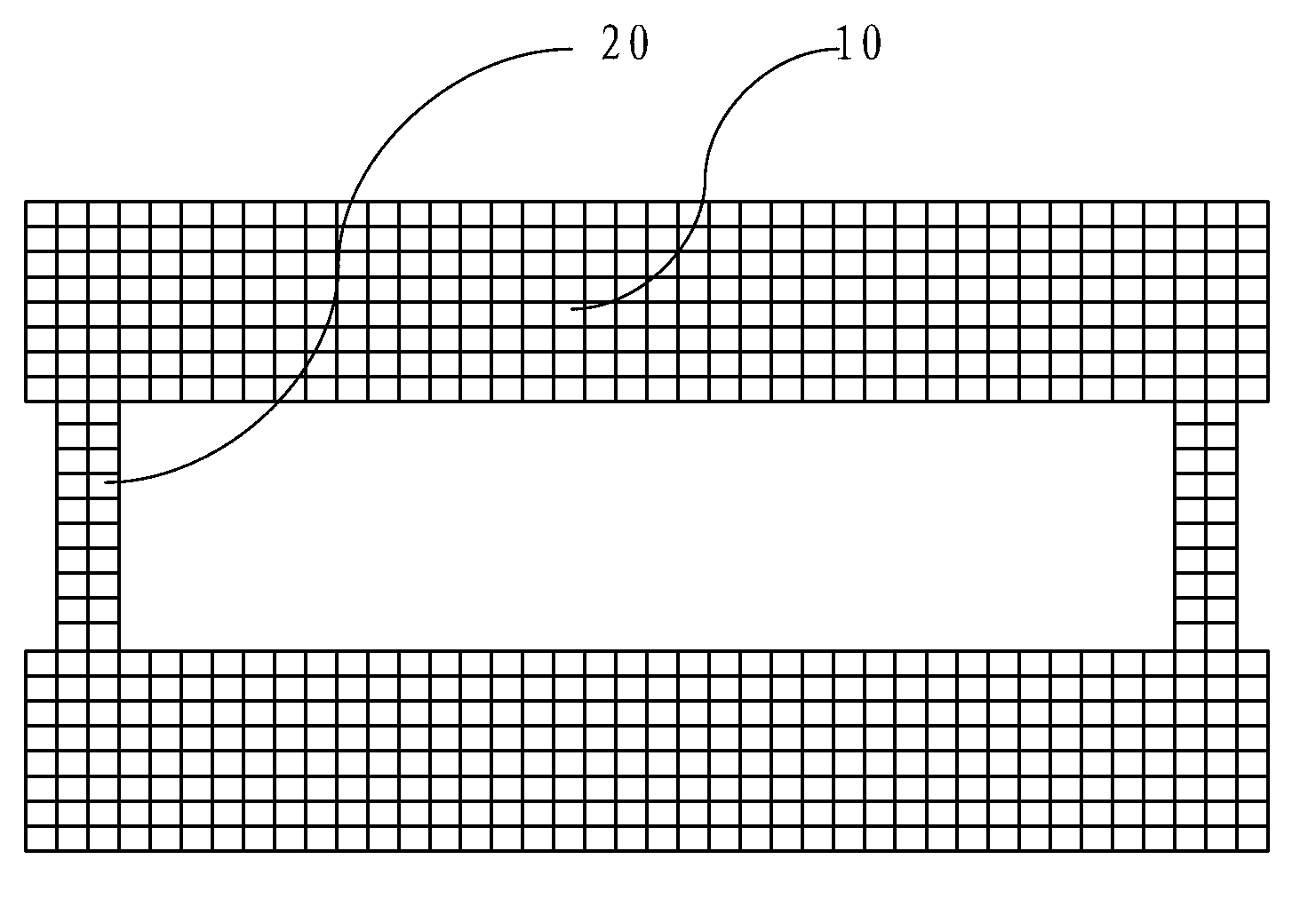

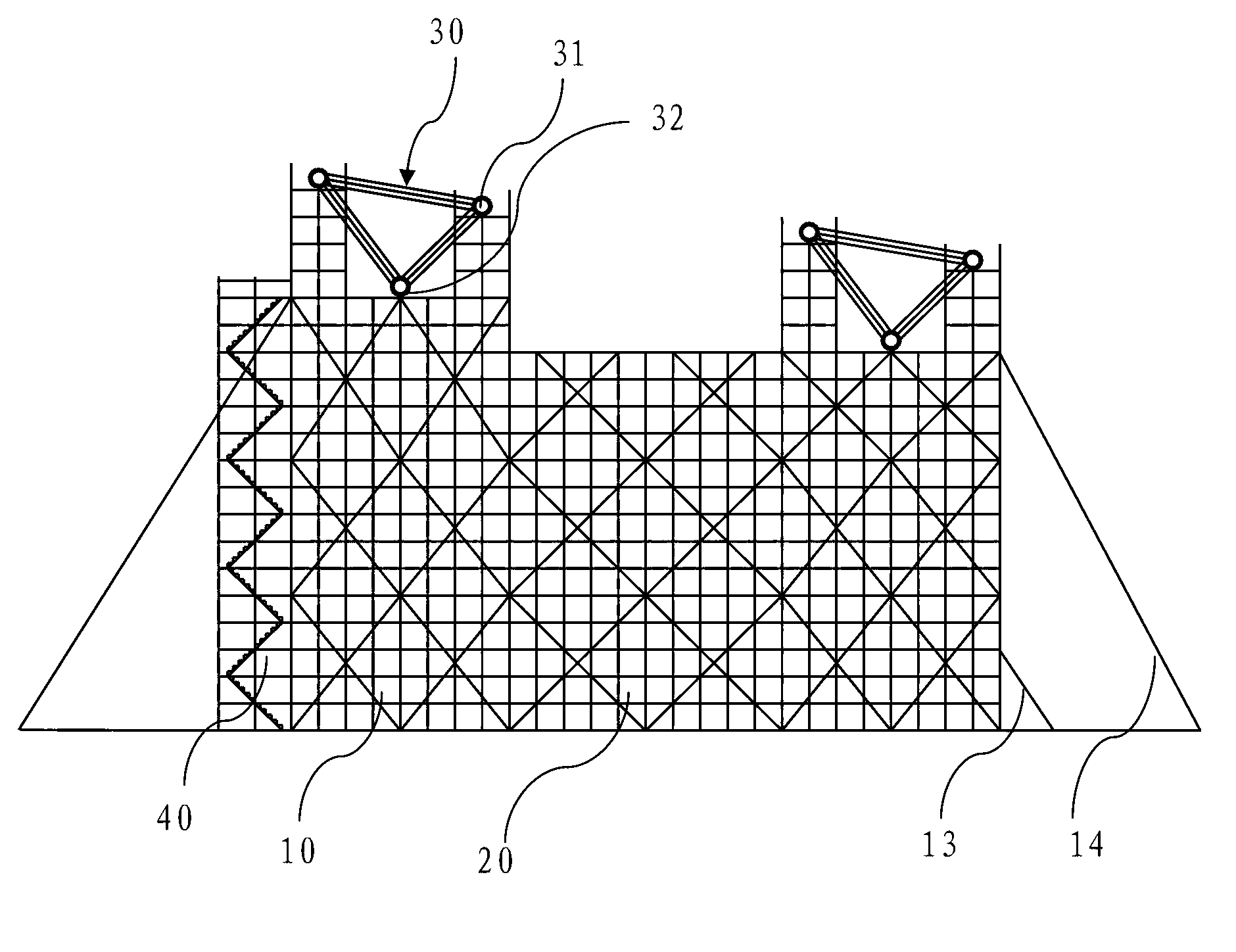

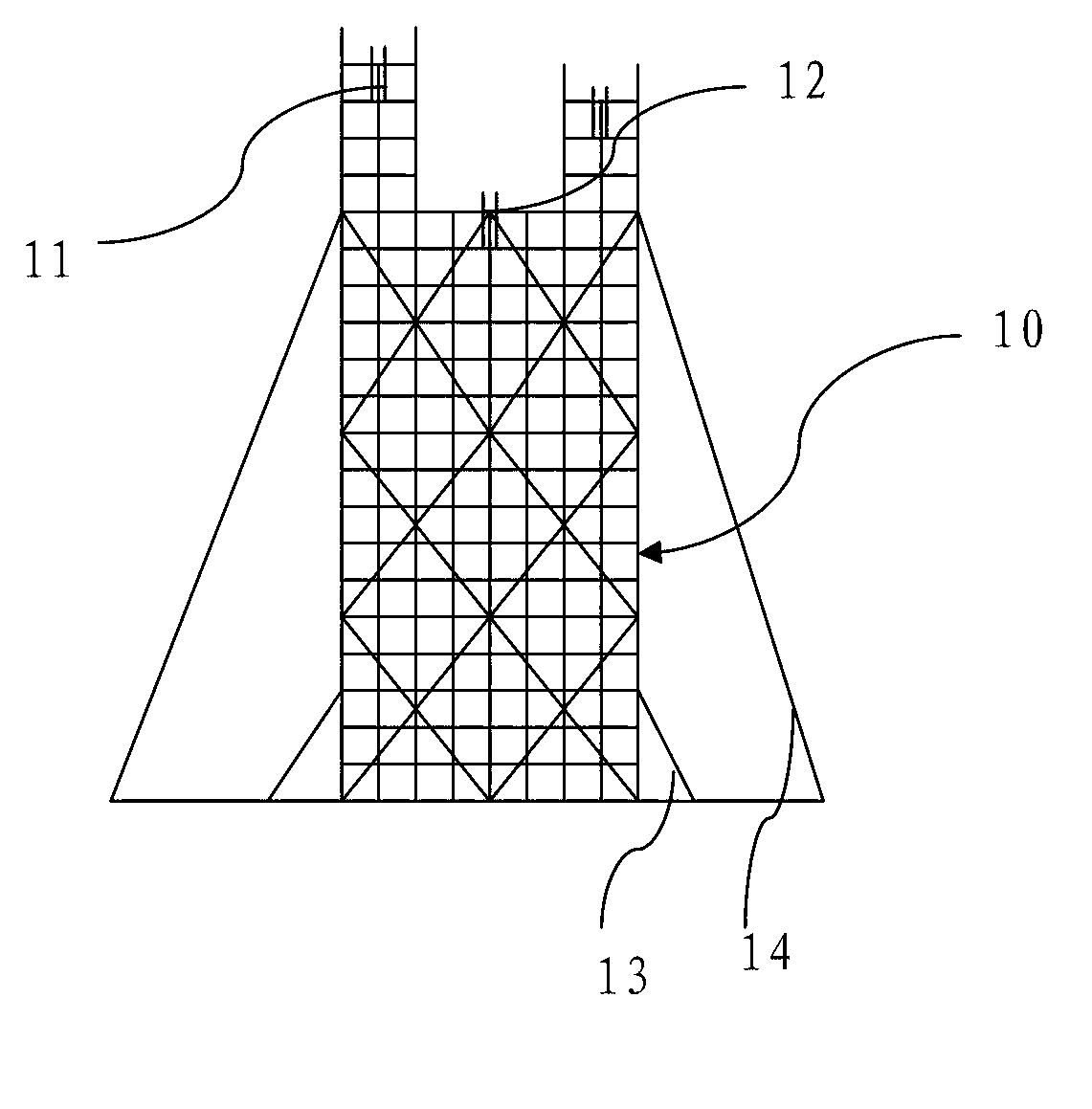

[0015] Such as figure 1 with figure 2 As shown, the large-span steel truss high-altitude scattered simple operation platform includes a single truss operation platform 10 and a connecting truss 20 connecting the single truss operation platform 10 together. The slot 11 and the lower chord support the steel pipe 12 . Build a passageway 40 for people on one side of the hand frame tire frame.

[0016] refer to figure 2 , the construction method of the large-span steel truss high-altitude scattered simple operation platform of the present invention comprises the following steps: building a strip-shaped scaffolding as a single-truss operating platform 10; setting up a connecting truss 20 to connect adjacent single-truss operating platforms; A plurality of jacking slots 11 and lower chord support steel pipes 12 are installed on the truss operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com