Valve timing changing device

A timing changing device and air distribution technology, which is applied to valve devices, engine components, machines/engines, etc., can solve problems such as increased size of shell rotor and blade rotor, knocking sound and poor movement, and wear of locking pins , to achieve the effect of miniaturization of the device, prevention of knocking noise and wear, and stable starting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

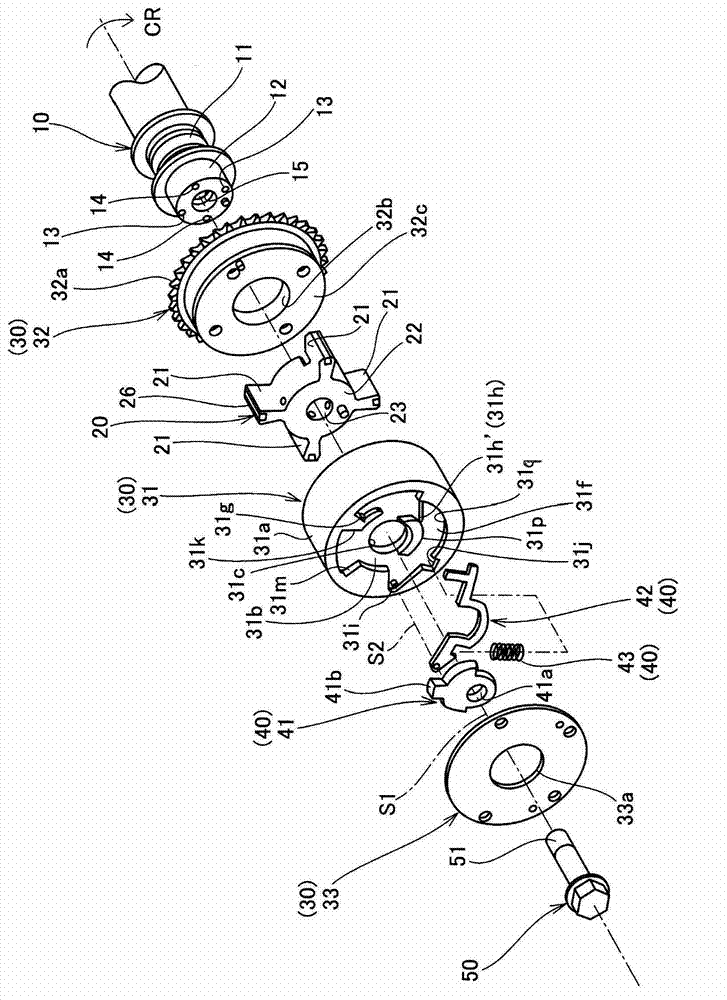

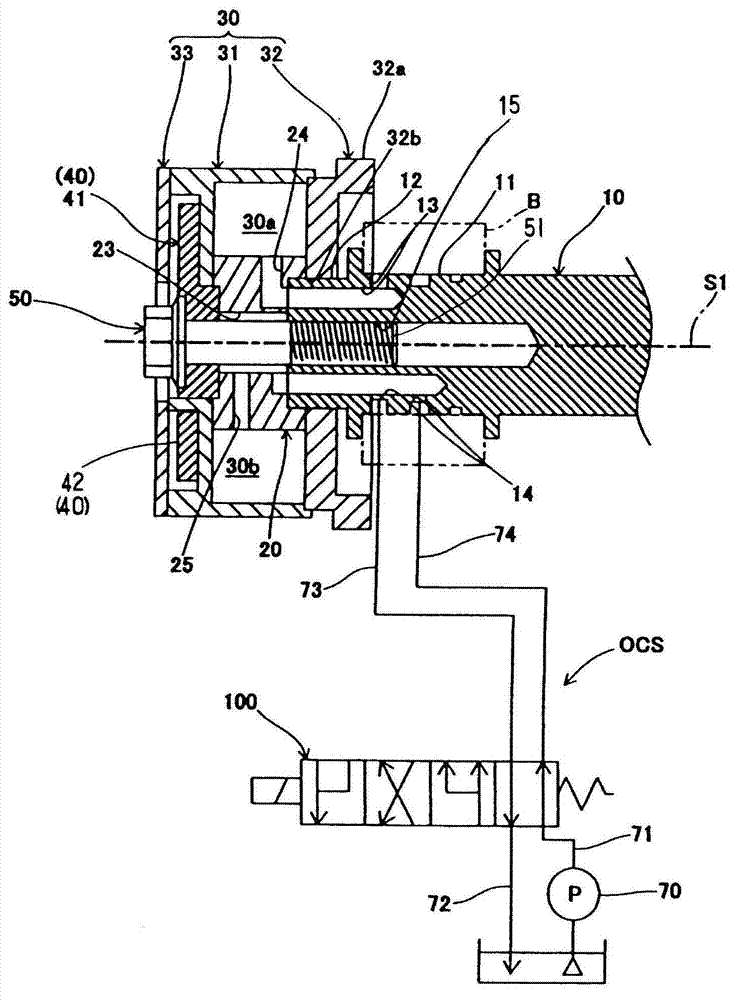

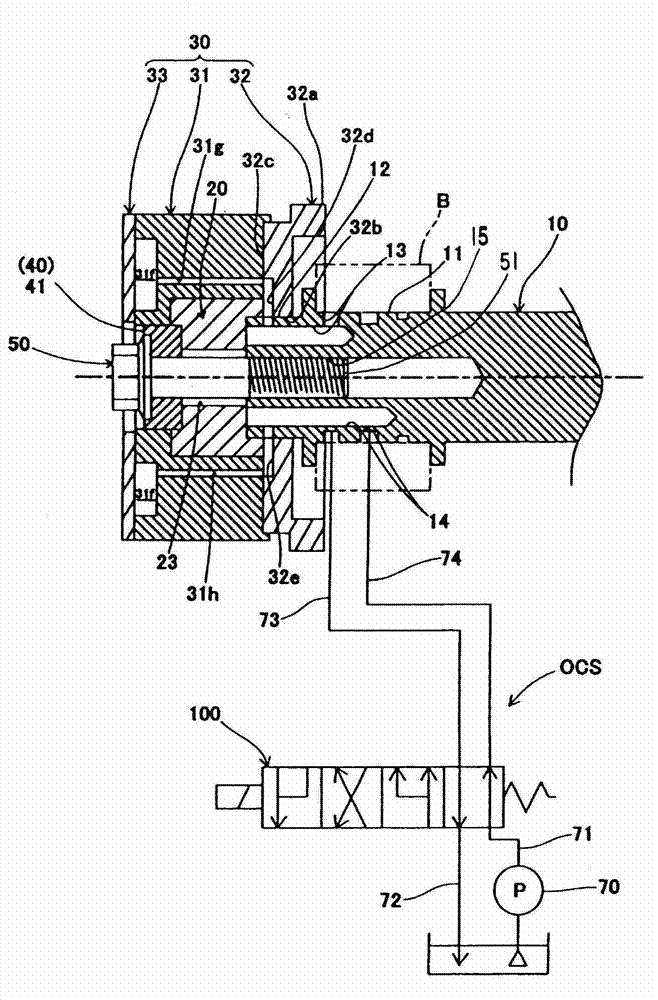

[0108] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0109] The valve timing changing device is a hydraulic valve timing changing device that uses the hydraulic pressure of the working oil in the engine to change the valve timing, such as Figure 1 to Figure 3 As shown, it includes the following components, etc.: a vane rotor 20 that is detachably fixed to the camshaft 10; a housing rotor 30 that rotates on the rotation axis S1 of the camshaft 10 and accommodates the vane rotor 20 as Can be rotated relatively, and the casing rotor 30 cooperates with the vane rotor 20 to define an advanced angle chamber 30a and a retarded angle chamber 30b; the locking mechanism 40 (locking cam 41, locking lever 42, force application member 43), its configuration The isolation chamber of the housing rotor 30 to lock the vane rotor 20 in the middle position relative to the housing rotor 30; the central bolt 50, which fastens the vane rotor ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap