Stuffing structure of split type stuffing box and stuffing replacing method

A stuffing box, split-type technology, applied in non-variable pumps, liquid fuel engines, components of pumping devices for elastic fluids, etc., can solve the problem that the quality of work cannot be guaranteed, and all packing cannot be taken out or installed Problems such as positioning and high labor intensity can be solved to achieve the effect of improving work efficiency and work quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

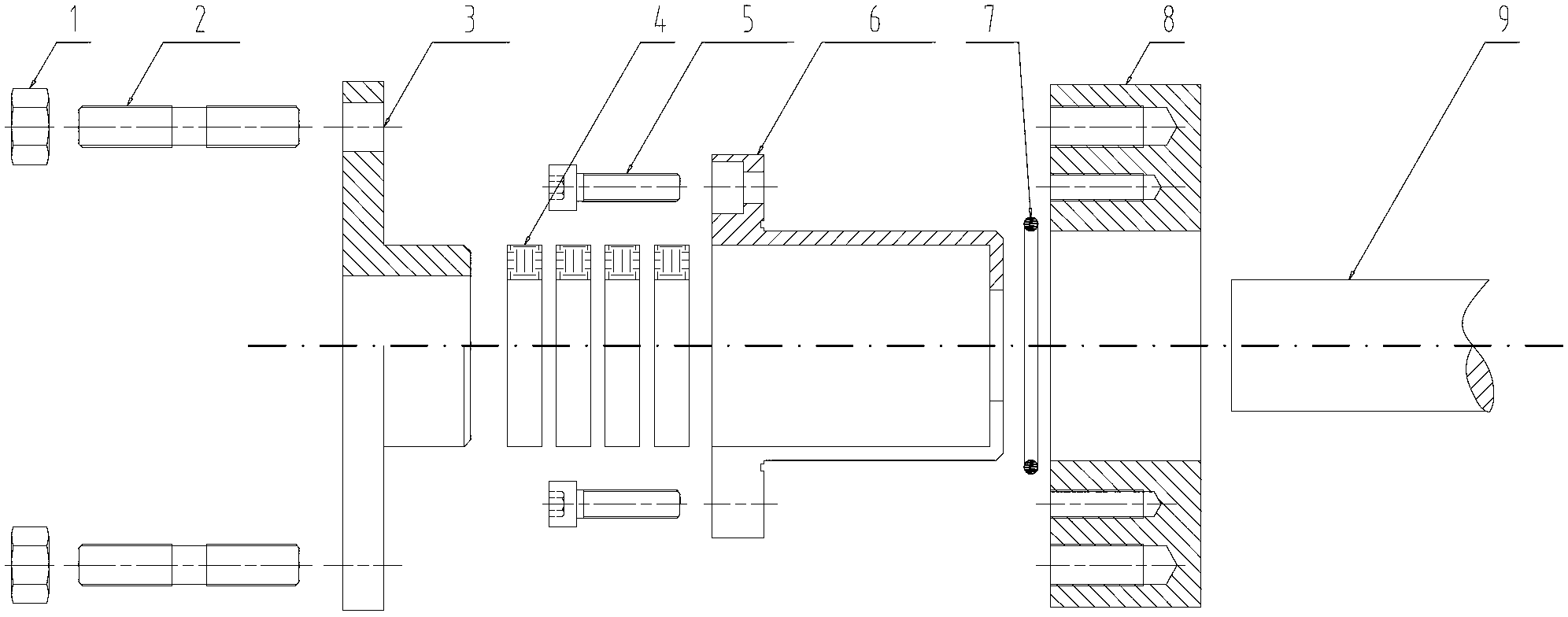

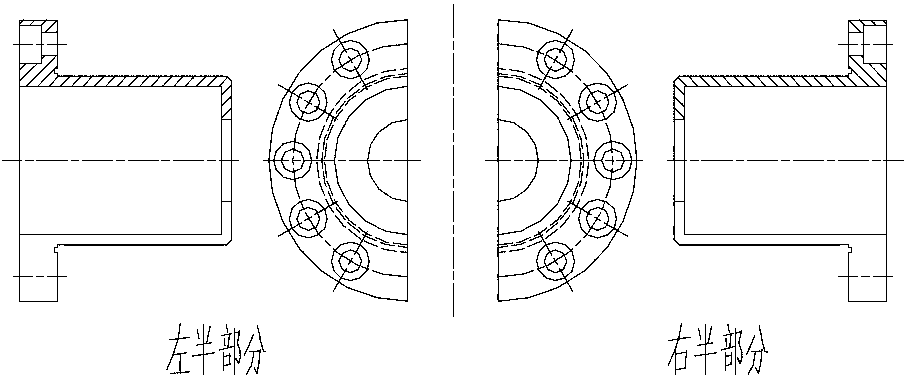

[0015] Combine below Figure 1 to Figure 2 detail

[0016] A split stuffing box stuffing structure and stuffing replacement method, which includes figure 2 The two semicircular sleeves on the left and right, the two semicircular sleeves 6 can be combined to form a cylindrical stuffing box. In addition, a fixed flange is provided on the outer end of the semicircular sleeve, and a flange hole is provided on the flange for connecting with the pump body. The inner end is provided with a shaft hole to allow the pump shaft to pass through.

[0017] After it is installed correctly, the attached figure 1 As shown, the semicircular sleeve 6 presses the O-ring 7 and positions it on the pump body 8 through ten hexagon socket bolts 5 to form a stuffing box, which is cup-shaped, so that the split stuffing box and the pump shaft 9 A circular space for accommodating the packing 4 is formed between them. Then put the packing 4 suitable for the specifications and sizes into the stuffing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com