Brake clearance manual adjusting arm device with umbrella tooth structures arranged at two ends of worm

A manual adjustment and brake clearance technology, applied in the direction of slack adjuster, etc., can solve the problems of damage to the adjustment shaft locking device, brake failure, and increase of brake clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

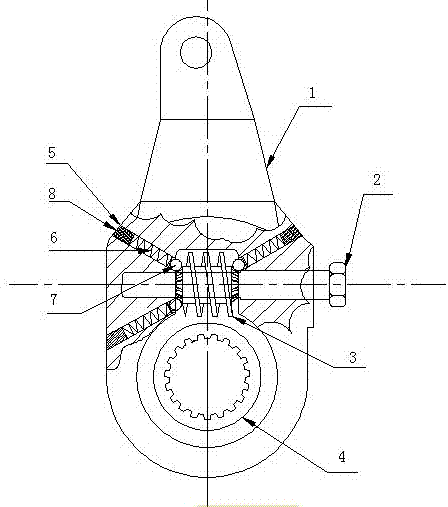

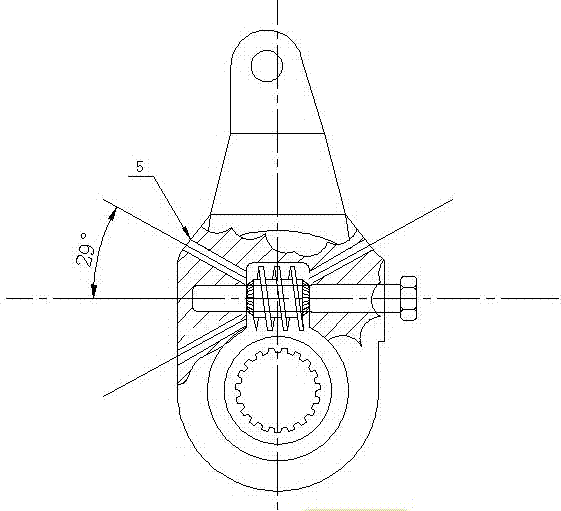

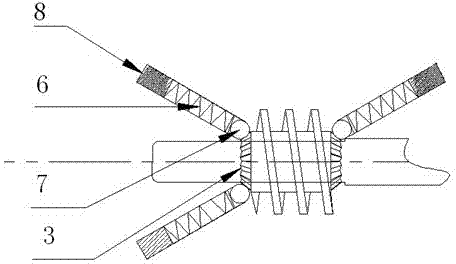

[0015] Such as figure 1 , figure 2 As shown, a brake gap manual adjustment arm device with a bevel tooth structure arranged at both ends of the worm, the locking adjustment arm of the worm with rack in the present invention mainly includes the adjustment arm housing (1), the adjustment shaft (2), the worm ( 3), the turbine (4) and other components, because there is an angled elastic material working hole (5) between the two matching surfaces of the adjustment arm housing (1) and the worm (3), the two ends of the worm (3) Bevel tooth structure and the steel ball (7) in the working hole (5) of elastic material match each other.

[0016] When adjusting the braking clearance of the vehicle, the worm shaft (2) rotates, and the bevel racks at both ends of the worm (3) rotate simultaneously, overcoming the pressure generated by the steel ball (7) in the working hole (5), and the steel ball (7) Move from the bottom of the bevel rack to the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com