Low cost and high efficiency ice machine

An ice maker and evaporator technology, applied in the directions of ice making, refrigerator, ice making, etc., can solve the problem of R-410A coolant/refrigerant transfer characteristics consideration, etc., to increase the heat transfer ratio, reduce the temperature difference, improve the The effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

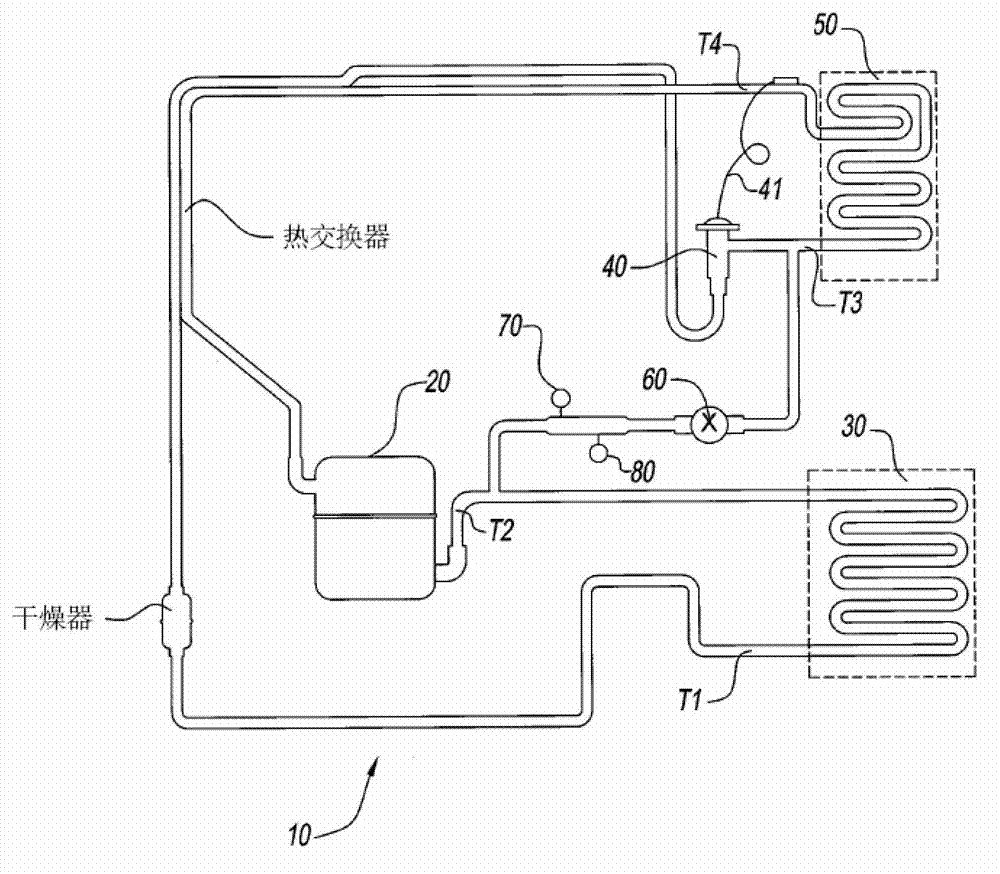

[0023] figure 1 A general flow diagram of the coolant / refrigerant system of an ice maker such as those that are the subject of this invention is depicted. figure 1In the closed coolant / refrigerant system 10 containing the coolant / refrigerant, the compressor 20 within the coolant / refrigerant system 10 is filled to a suitable level with a suitable gaseous coolant / refrigerant. The compressor 20 increases the pressure of the coolant / refrigerant thereby increasing the temperature of the coolant / refrigerant. As the compressor 20 pressurizes the entire system, the coolant / refrigerant exits the compressor 20 and passes along it to the condenser 30 where the high pressure coolant / refrigerant releases its heat and liquefies. The high-pressure coolant / refrigerant releases its heat via ambient heat exchange with the environment in the form of the high-pressure coolant / refrigerant passing through the serpentine-like coils of the condenser. The coolant / refrigerant leaves the condenser a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com