Process and system for producing light hydrocarbon and LNG (Liquefied Natural Gas) from oilfield associated gas

A technology for oilfield associated gas and light hydrocarbons, which is used in the petroleum industry, gas fuel, liquid hydrocarbon mixture recovery, etc., and can solve the problems of complex cold boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

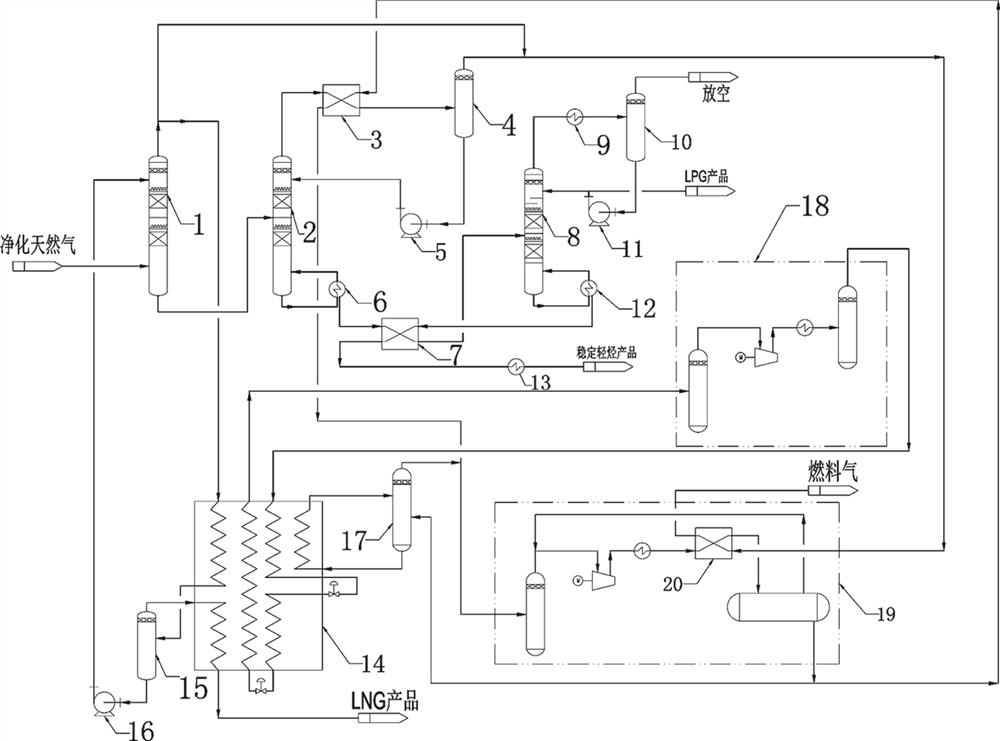

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] Such as figure 1 , The system embodiment of the present invention includes a low temperature scrubber 1, a demethylation ethane tower 2, a liquefied gas tower 8, a low temperature separator 15, a demethylation ethane tower top condenser 3 and a cold box 14. The low-temperature scrubber 1 has an inlet port, an outlet port, a washing liquid inlet port and a heavy hydrocarbon outlet used as the inlet of oilfield associated gas (which has been decarburized and dehydrated before entering the system). The gas outlet port is connected to the first The inlet and the gas outlet port of the low-temperature scrubber 1 can also be connected with fuel gas pipes through pipelines. The first outlet of the cold box 14 is connected to the inlet of the low-temperature separator 15 by a pipeline, and the first outlet of the low-temperature separator 15 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com